How to Select and Install a Coupling

Servo motors, stepper motors, intelligent motors, and ball screws are widely used in machine tools and automation, and flexible couplings are widely used to transfer torque and protect motors and lead screws. However, most people are unaware of how to use the coupling. Unreasonable selection of couplings and incorrect installation are common occurrences, resulting in an increasing number of couplings being damaged. Due to the unexpected shutdown, the production of the loss is also greater. This paper describes how to select and install a coupling in conjunction with MOONS' coupling products.  ● Refer to the coupling size table, according to the drive shaft diameter, select the appropriate size of the coupling.

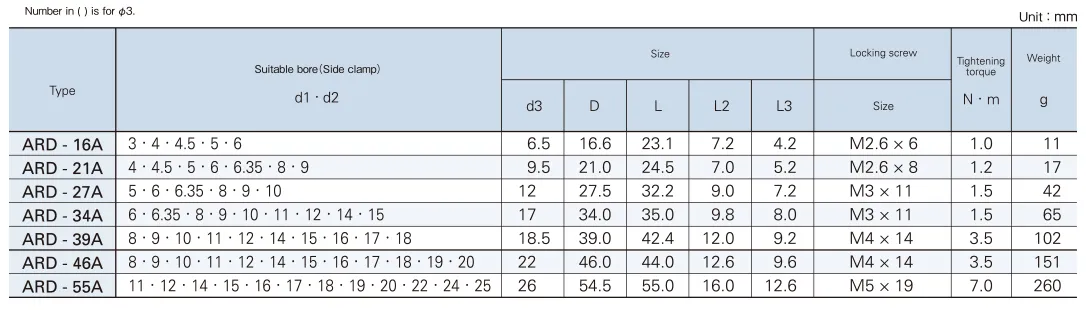

● Refer to the coupling size table, according to the drive shaft diameter, select the appropriate size of the coupling.

● After confirming that there is no axial force on the coupling, start locking the screws.

● After confirming that there is no axial force on the coupling, start locking the screws.

A. Choose steps

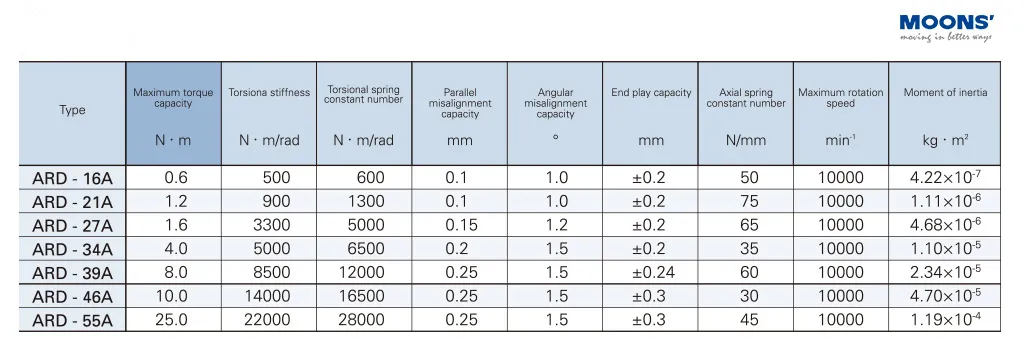

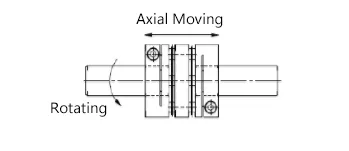

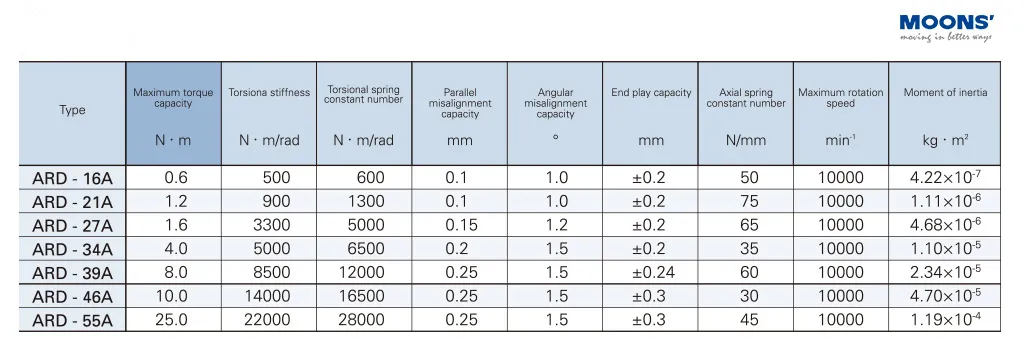

● Calculate the torque(Ta) applied to the coupling Ta (Nm) =P (Kw)*9550/N (rpm) Remark: P: The power output of the driving motor is described by stepper motors as holding torque, AC motors as rated torque, and servo motors as maximum torque. N: the working speed. ● Calculate the compensating torque (Td) applied to the coupling. Td=Ta * K, Remark: K is the safety factor (K=1.2 ~ 1.5) As long as the maximum torque capacity of the coupling exceeds Td, the coupling selection data should be checked according to the compensation torque value. ● Refer to the coupling size table, according to the drive shaft diameter, select the appropriate size of the coupling.

● Refer to the coupling size table, according to the drive shaft diameter, select the appropriate size of the coupling.

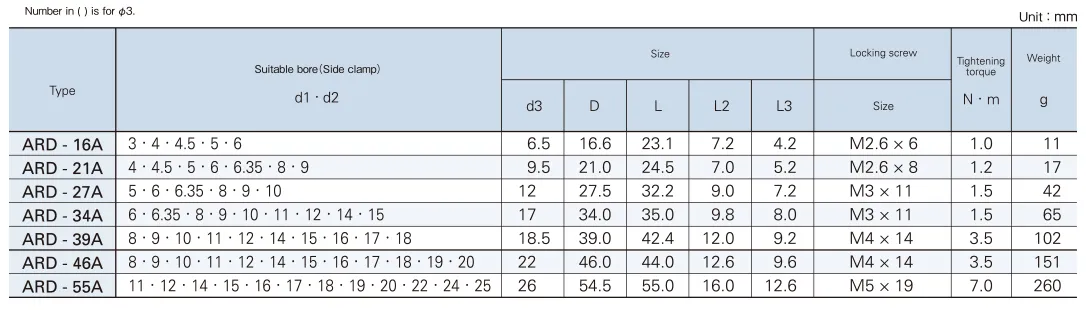

B. Installation of coupling

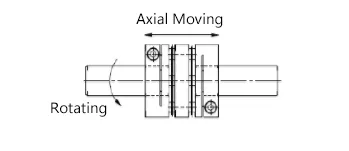

When the coupling is strongly impacted, the assembly results will be affected, so professional intervention is required. The product can be damaged during installation, so please handle it with care. The following steps are required for installation: ● Loosen clamp screw, clean shaft surface, and inner hole of coupling. ● When installing couplings, avoid applying an external force to elastic components such as compression and traction. The coupling may be subjected to excessive compression force after installation. ● When the locking screw is loose, it is necessary to verify that the coupling can move easily along the axial and rotational directions. If cannot be moved, please readjust the axis's concentricity. ● After confirming that there is no axial force on the coupling, start locking the screws.

● After confirming that there is no axial force on the coupling, start locking the screws.