In addition to providing high-performance hybrid stepper linear motors, MOONS' provides high-quality leadscrews and nuts, opening up new avenues for equipment designers who need high performance and superior durability. The MOONS' actuators generate more force than similar actuators due to their special stator geometry and optimized magnet materials.

Our proven permanent magnet linear actuators are ideal for simple designs with lower performance requirements.

There are four types of linear stepper motors: external drive linear stepper motors (including lead screw and ball screw), straight shaft linear stepper motors, push rod linear stepper motors, and permanent magnet linear stepper motors.

Our proven permanent magnet linear actuators are ideal for simple designs with lower performance requirements.

There are four types of linear stepper motors: external drive linear stepper motors (including lead screw and ball screw), straight shaft linear stepper motors, push rod linear stepper motors, and permanent magnet linear stepper motors.

External Nut Hybrid Linear Stepper Motors

External Nut linear actuator for easy installation and reliable performance.

Non-captive Hybrid Linear Stepper Motors

Non-captive hybrid linear stepper motors for easy installation and reliable performance.

Captive Hybrid Linear Stepper Motors

Captive linear actuator for easy installation and reliable performance.

Ball Screw Hybrid Linear Stepper Motors

Ball screw external nut linear actuator for easy installation and reliable performance.

Permanent Magnet Linear Stepper Motors

MOONS' offers two types of PM linear stepper motors: Permanent Magnet (PM) Stepper Motor Non-Captive and Captive, with push/pull force ratings of 24N(86.3oz) to 50N(179.9oz).

What is the positioning accuracy and repeatability of a linear stepper motor?

Positioning accuracy:error on the estimated position of a receiver related to the true position.Ball Screw Positioning Accuracy:±0.052mm/300mm

Lead Screw Positioning Accuracy:±0.21mm/300mm

Repeatability:the closeness of the agreement between the results of successive measurements of the same measure, when carried out under the same conditions of measurement.

Ball Screw Repeatability:±0.02mm

Lead Screw with Standard Nut Repeatability:±0.05mm

Lead Screw with Anti-BacklashBlack Nut Repeatability:±0.02mm

Comparison chart of positioning accuracy and repeatability

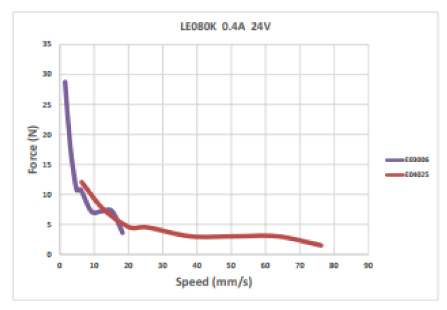

What is the maximum speed of a linear stepper motor?

As the speed of a linear stepping motor increases, the torque will decrease, so when selecting a linear stepping motor, you need to refer to the speed-thrust table for selection. (see example following)

How to calculate the linear travel / step of a linear stepper motor?

travel/step refers to the displacement of the slider in the axial direction every time the motor rotates by a step angle.Travel/Step=Leads/( 360°/Step Angle )

Lead is the linear travel the nut makes per one screw revolution

Pitch is the distance between screw grooves and is commonly used with inch sized products and specified as threads per inch. The pitch and lead are equal with single start screws. For multiple start screws the lead is the pitch multiplied by the number of starts.

How to solve the noise problem of linear stepping motor?

Check if the stepper motor is running in the low speed resonance area. When the stepper motor runs within 200pps, it is prone to low frequency resonance, and it is necessary to avoid this working range as much as possible.When the thrust is greater than the load, the drive current can be reduced to reduce noise

Use MOONS' recommended grease to greatly reduce noise and increase nut life

For stepper-servo motors, check if the PID parameters are reasonable

If you are using a MOONS' driver, you can enable anti-resonance, torque ripple smoothing, microstep emulation, etc. to reduce noise

Download

| Linear Motion Product General Catalogue   |

LE08 Series

LE08 Series

LE11 Series

LE11 Series  LE14 Series

LE14 Series  LE17 Series

LE17 Series  LE23 Series

LE23 Series  LN08 Series

LN08 Series  LN11 Series

LN11 Series  LN14 Series

LN14 Series  LN17 Series

LN17 Series  LN23 Series

LN23 Series  LC08 Series

LC08 Series  LC11 Series

LC11 Series  LC14 Series

LC14 Series  LC17 Series

LC17 Series  LC23 Series

LC23 Series  BE11 Series

BE11 Series  BE14 Series

BE14 Series  BE17 Series

BE17 Series  BE23 Series

BE23 Series