The difference between brushed motors and brushless motors

Brushless motors and brushed motors can be distinguished by their different structures, working principles, and parameters. Brushed motors and brushless motors have different structures or working principles, which makes them easy to distinguish.  Iron core motor

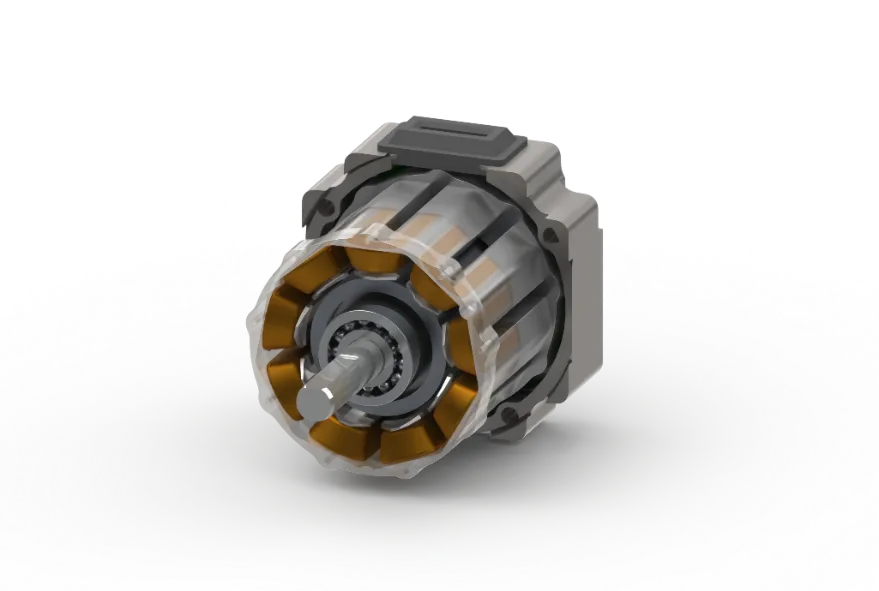

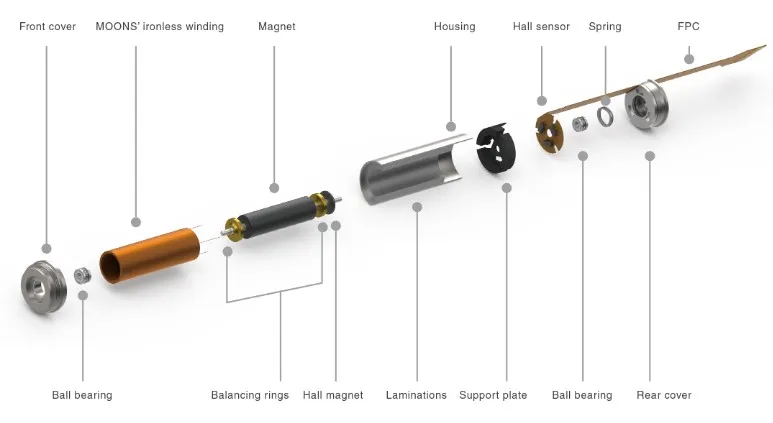

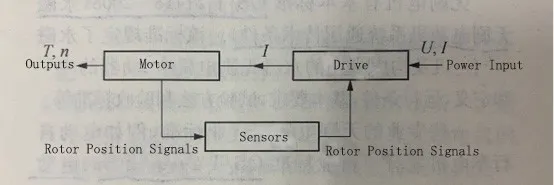

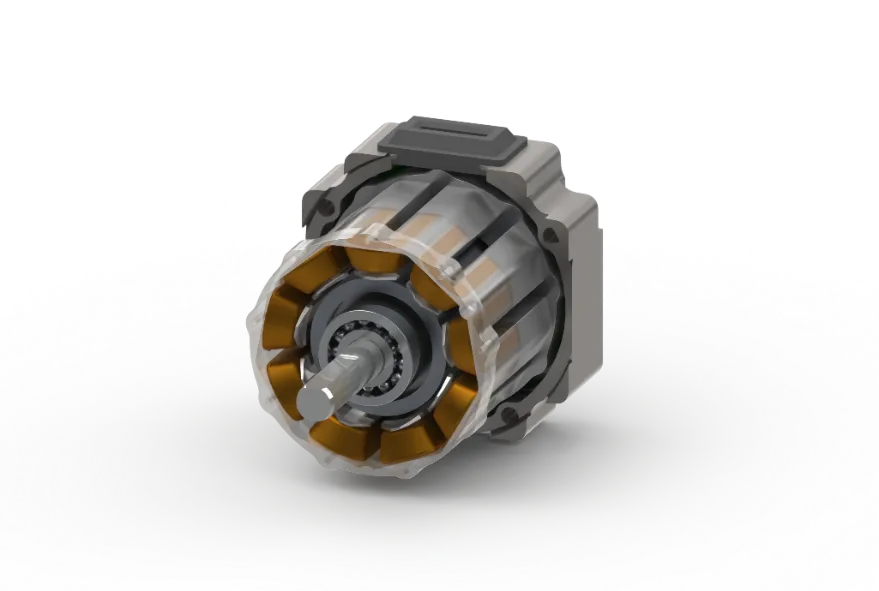

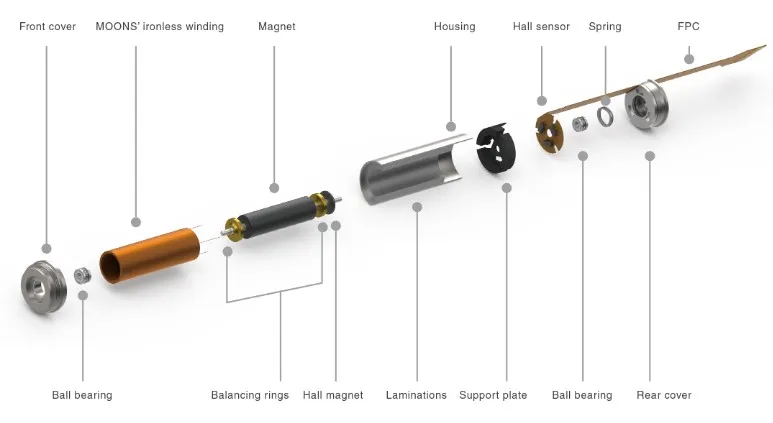

Iron core motor  Brushed coreless motor Brushless motor structure: There are many varieties of brushless motors with different structures. To form a brushless motor system, it consists of a rotor, a stator, and a motor control part. Permanent magnets are used in the rotor, and coil windings and iron cores are used in the stator. In the motor control part, switching and phase detection components are included as well as a brushless motor controller. A rotor is composed of an outer rotor and an inner rotor. On the rotor, there are multi-pole block magnets or annular magnets. There are windings on the stator poles. To control the normal switching of the motor, position detection components and controllers are placed at specific locations on the stator. Phase, most of them now use Hall elements, and there are other methods for controlling commutation. When the electronic switching part of the brushless motor is not taken into consideration, the brushless motor's structure can be compared with the structure of an AC synchronous motor.

Brushed coreless motor Brushless motor structure: There are many varieties of brushless motors with different structures. To form a brushless motor system, it consists of a rotor, a stator, and a motor control part. Permanent magnets are used in the rotor, and coil windings and iron cores are used in the stator. In the motor control part, switching and phase detection components are included as well as a brushless motor controller. A rotor is composed of an outer rotor and an inner rotor. On the rotor, there are multi-pole block magnets or annular magnets. There are windings on the stator poles. To control the normal switching of the motor, position detection components and controllers are placed at specific locations on the stator. Phase, most of them now use Hall elements, and there are other methods for controlling commutation. When the electronic switching part of the brushless motor is not taken into consideration, the brushless motor's structure can be compared with the structure of an AC synchronous motor.  slotted motor

slotted motor  Structural diagram of slotless motor

Structural diagram of slotless motor  Work principle of the brushless motor

Work principle of the brushless motor  Brushless motor: Brushless motors generally have 3 wires (without Hall) or 8 wires (with Hall), and a few 2 wires (built-in driver). They are wired in the form of a wire harness and are divided into square and round body.

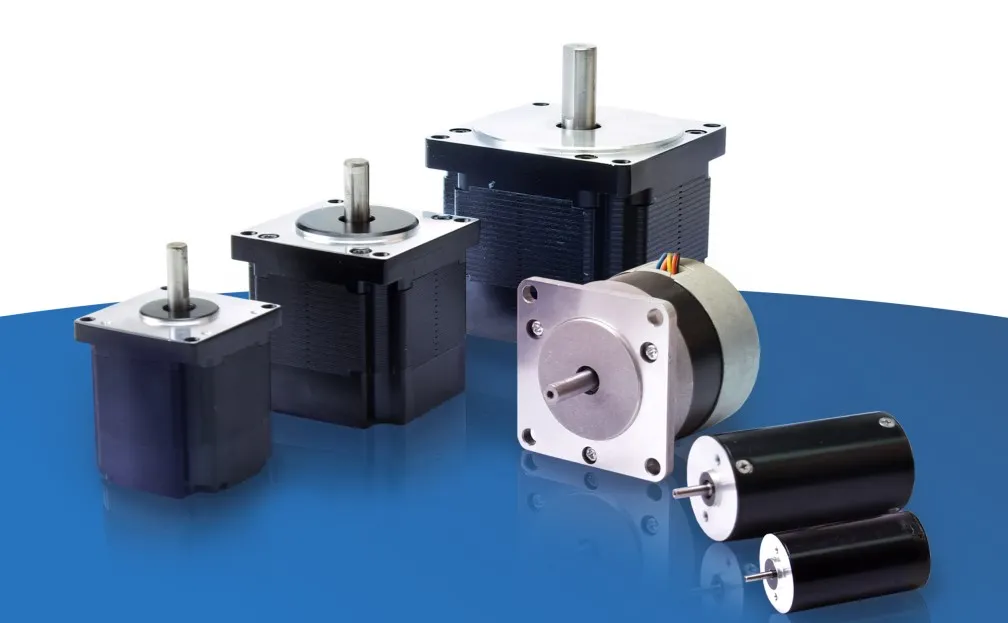

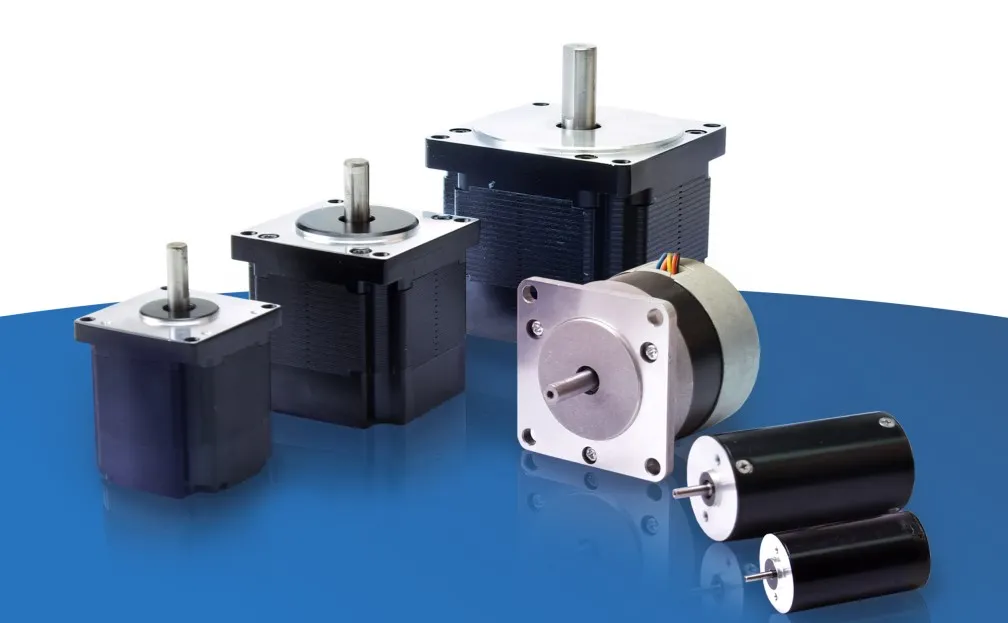

Brushless motor: Brushless motors generally have 3 wires (without Hall) or 8 wires (with Hall), and a few 2 wires (built-in driver). They are wired in the form of a wire harness and are divided into square and round body.  MOONS' brushless motor products A brushless motor can be understood in this way: It is a type of motor that uses electronic commutation to replace the mechanical commutator in brushed motors. Brushless motors have mechanical properties that are very similar to those of brushed motors. A comparison of the performance of brushed motors and brushless motors is presented in the following table.

MOONS' brushless motor products A brushless motor can be understood in this way: It is a type of motor that uses electronic commutation to replace the mechanical commutator in brushed motors. Brushless motors have mechanical properties that are very similar to those of brushed motors. A comparison of the performance of brushed motors and brushless motors is presented in the following table.

Basic performance of drive motor In terms of power density, peak efficiency, speed range, reliability, operating life, and structural solidity, brushless motors perform better than brushed motors. Only the controller is more expensive than brushed motors. In terms of performance and other factors, it is more advantageous than brushed motors. It is anticipated that with the rapid development and popularization of electronic control technology, the cost of controllers will be lower, the size will be smaller, and the power density will be higher. National defense and military, aerospace, office machinery, computers, audio, ventilation, household air conditioning, automatic control, instrumentation, automobiles, and other fields make extensive use of brushless motors. MOONS' slotless & coreless series motors feature patented windings. This special design provides high torque, high torque, and low noise, and the product can be purchased directly online.  Slotless Brushless DC motor EC series Slotless Brushless DC motors are available in a variety of outer diameter and body length specifications such as Ø13mm, Ø16mm, Ø22mm, etc. Each series provides multiple rated voltage versions.

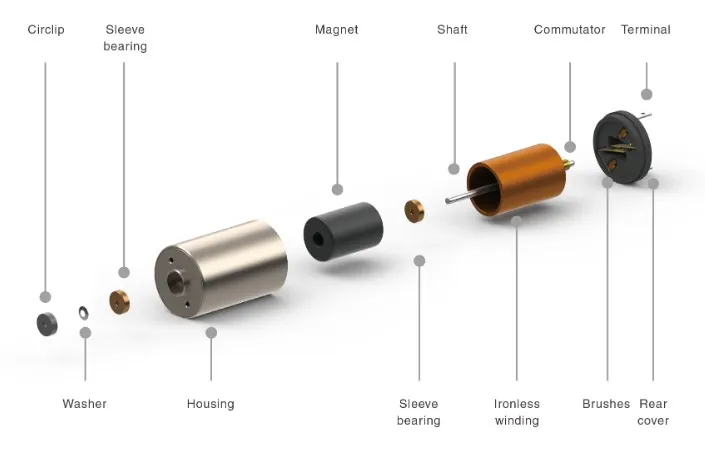

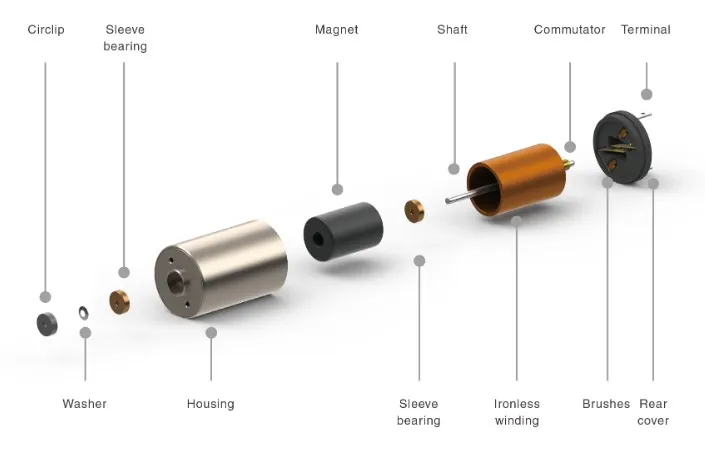

Slotless Brushless DC motor EC series Slotless Brushless DC motors are available in a variety of outer diameter and body length specifications such as Ø13mm, Ø16mm, Ø22mm, etc. Each series provides multiple rated voltage versions.  Coreless Brushed DC Motor DCU series Coreless Brushed DC Motors are available in a variety of outer diameter and body length specifications from Ø8mm to Ø24mm. They adopt a hollow rotor design and feature high acceleration, low moment of inertia, no cogging effect, no iron loss, small size and light weight.

Coreless Brushed DC Motor DCU series Coreless Brushed DC Motors are available in a variety of outer diameter and body length specifications from Ø8mm to Ø24mm. They adopt a hollow rotor design and feature high acceleration, low moment of inertia, no cogging effect, no iron loss, small size and light weight.  Brushless DC motor Brushless DC motors can benefit customers by optimizing their design to reduce noise, reduce vibration, and extend working life.

Brushless DC motor Brushless DC motors can benefit customers by optimizing their design to reduce noise, reduce vibration, and extend working life.

The structural difference between brushed motors and brushless motors

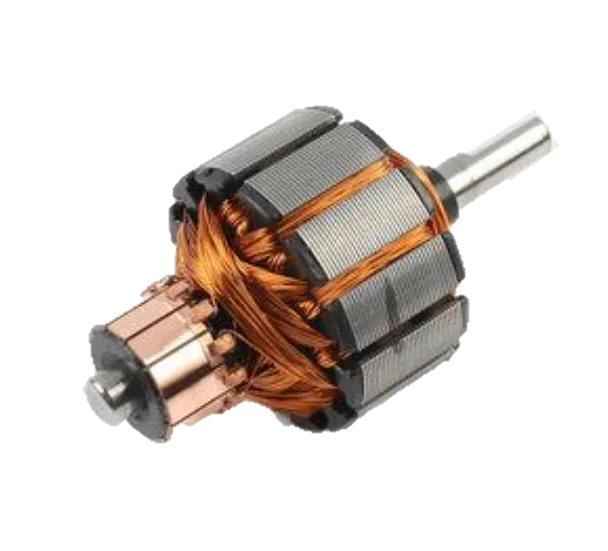

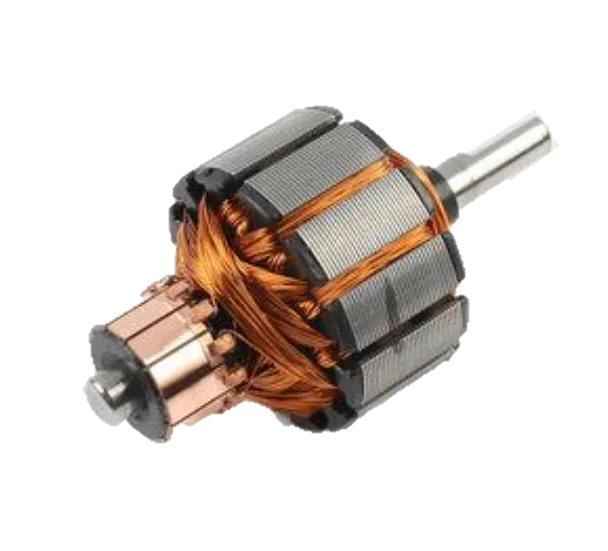

Brushed motor structure: A brushed motor consists of a rotating motor containing a brush device that converts electrical energy into mechanical energy (motor). Iron core motor

Iron core motor  Brushed coreless motor Brushless motor structure: There are many varieties of brushless motors with different structures. To form a brushless motor system, it consists of a rotor, a stator, and a motor control part. Permanent magnets are used in the rotor, and coil windings and iron cores are used in the stator. In the motor control part, switching and phase detection components are included as well as a brushless motor controller. A rotor is composed of an outer rotor and an inner rotor. On the rotor, there are multi-pole block magnets or annular magnets. There are windings on the stator poles. To control the normal switching of the motor, position detection components and controllers are placed at specific locations on the stator. Phase, most of them now use Hall elements, and there are other methods for controlling commutation. When the electronic switching part of the brushless motor is not taken into consideration, the brushless motor's structure can be compared with the structure of an AC synchronous motor.

Brushed coreless motor Brushless motor structure: There are many varieties of brushless motors with different structures. To form a brushless motor system, it consists of a rotor, a stator, and a motor control part. Permanent magnets are used in the rotor, and coil windings and iron cores are used in the stator. In the motor control part, switching and phase detection components are included as well as a brushless motor controller. A rotor is composed of an outer rotor and an inner rotor. On the rotor, there are multi-pole block magnets or annular magnets. There are windings on the stator poles. To control the normal switching of the motor, position detection components and controllers are placed at specific locations on the stator. Phase, most of them now use Hall elements, and there are other methods for controlling commutation. When the electronic switching part of the brushless motor is not taken into consideration, the brushless motor's structure can be compared with the structure of an AC synchronous motor.  slotted motor

slotted motor  Structural diagram of slotless motor

Structural diagram of slotless motor The principle difference between brush motor and brushless motor

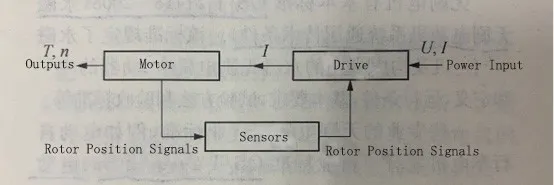

Principle of brush motor: The brushed motor does not require a driver and completes commutation mechanically. A segmented copper sleeve, called a commutator, is installed on the motor shaft. Brushes slide along the commutator as the motor rotates, coming into contact with different commutator segments. This creates a dynamic magnetic field inside the motor. Due to their relative sliding, brushes, and commutators are the most susceptible to wear. Due to the presence of brushes, it is referred to as "brushed". A brushless motor consists of a motor body and a driver, also called an electronic commutated motor. As opposed to brushed motors, brushless motors have the opposite structure: The rotor is a coil winding connected to the output shaft and the stator is a permanent magnet; the rotor of brushless motors is a permanent magnet, connected to the output shaft, and the stator is a coil winding. Since there are no brushes, it is called "brushless". The brushless motor is a mechatronic device that consists of a motor, a sensor, and a driver. The position sensor detects the magnetic pole signal from the rotor. Based on this signal, the controller performs logical processing and generates the corresponding switch signal. A certain sequence of events triggers the switch signal. In the driver, a power switching device distributes the power supply current to each phase winding of the motor in a logical manner, causing the motor to rotate and generate continuous torque. The following figure shows the working principle of the brushless motor. Work principle of the brushless motor

Work principle of the brushless motor The difference between brushed motors and brushless motors

Brushed motors: Under normal circumstances, brushed motors can be distinguished by the form of the wires, usually 2 wires, in the form of wire harnesses or terminals, and most of them have round bodies. Brushless motor: Brushless motors generally have 3 wires (without Hall) or 8 wires (with Hall), and a few 2 wires (built-in driver). They are wired in the form of a wire harness and are divided into square and round body.

Brushless motor: Brushless motors generally have 3 wires (without Hall) or 8 wires (with Hall), and a few 2 wires (built-in driver). They are wired in the form of a wire harness and are divided into square and round body.  MOONS' brushless motor products A brushless motor can be understood in this way: It is a type of motor that uses electronic commutation to replace the mechanical commutator in brushed motors. Brushless motors have mechanical properties that are very similar to those of brushed motors. A comparison of the performance of brushed motors and brushless motors is presented in the following table.

MOONS' brushless motor products A brushless motor can be understood in this way: It is a type of motor that uses electronic commutation to replace the mechanical commutator in brushed motors. Brushless motors have mechanical properties that are very similar to those of brushed motors. A comparison of the performance of brushed motors and brushless motors is presented in the following table. | Project | Brushed motor | Brushless motor |

| Power density | low | high |

| Peak efficiency (%) | 85~89 | 95~97 |

| Load efficiency (%) | 80~87 | 85~97 |

| Speed range (r/min) | 1000~10000 | 500~10000 |

| Reliability | Average | Excellent |

| Operating life | short | long |

| Structural sturdiness | Poor | Average |

| Motor dimensions | large | small |

| Control operation performance | Good | Good |

| Controller cost | low | high |

Slotless Brushless DC motor EC series Slotless Brushless DC motors are available in a variety of outer diameter and body length specifications such as Ø13mm, Ø16mm, Ø22mm, etc. Each series provides multiple rated voltage versions.

Slotless Brushless DC motor EC series Slotless Brushless DC motors are available in a variety of outer diameter and body length specifications such as Ø13mm, Ø16mm, Ø22mm, etc. Each series provides multiple rated voltage versions.  Coreless Brushed DC Motor DCU series Coreless Brushed DC Motors are available in a variety of outer diameter and body length specifications from Ø8mm to Ø24mm. They adopt a hollow rotor design and feature high acceleration, low moment of inertia, no cogging effect, no iron loss, small size and light weight.

Coreless Brushed DC Motor DCU series Coreless Brushed DC Motors are available in a variety of outer diameter and body length specifications from Ø8mm to Ø24mm. They adopt a hollow rotor design and feature high acceleration, low moment of inertia, no cogging effect, no iron loss, small size and light weight.  Brushless DC motor Brushless DC motors can benefit customers by optimizing their design to reduce noise, reduce vibration, and extend working life.

Brushless DC motor Brushless DC motors can benefit customers by optimizing their design to reduce noise, reduce vibration, and extend working life.