What is the type of DC servo motor?

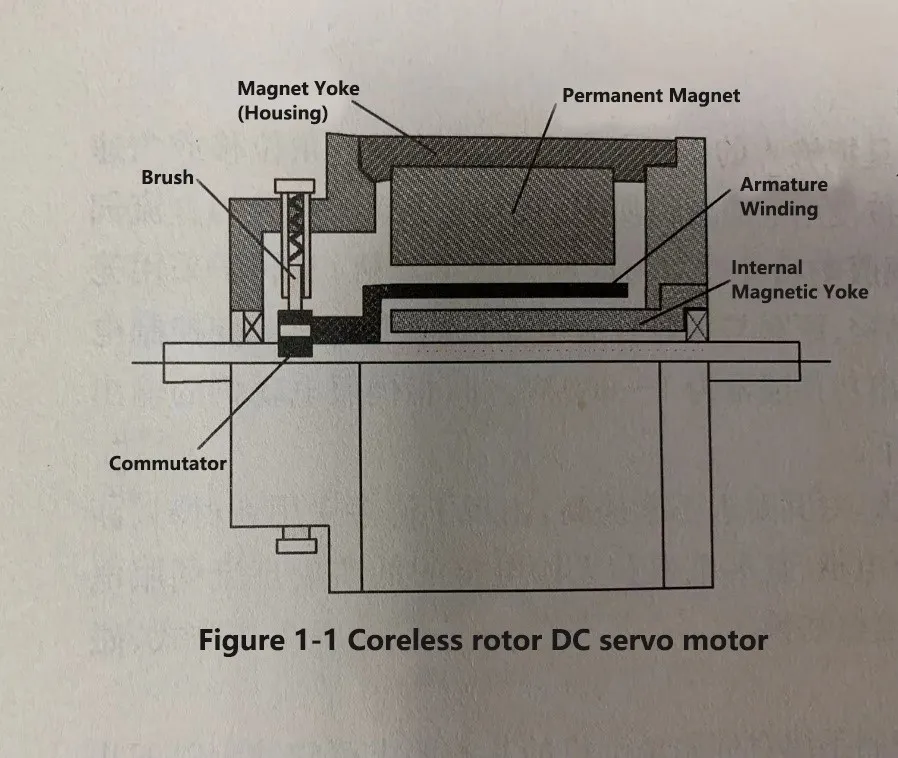

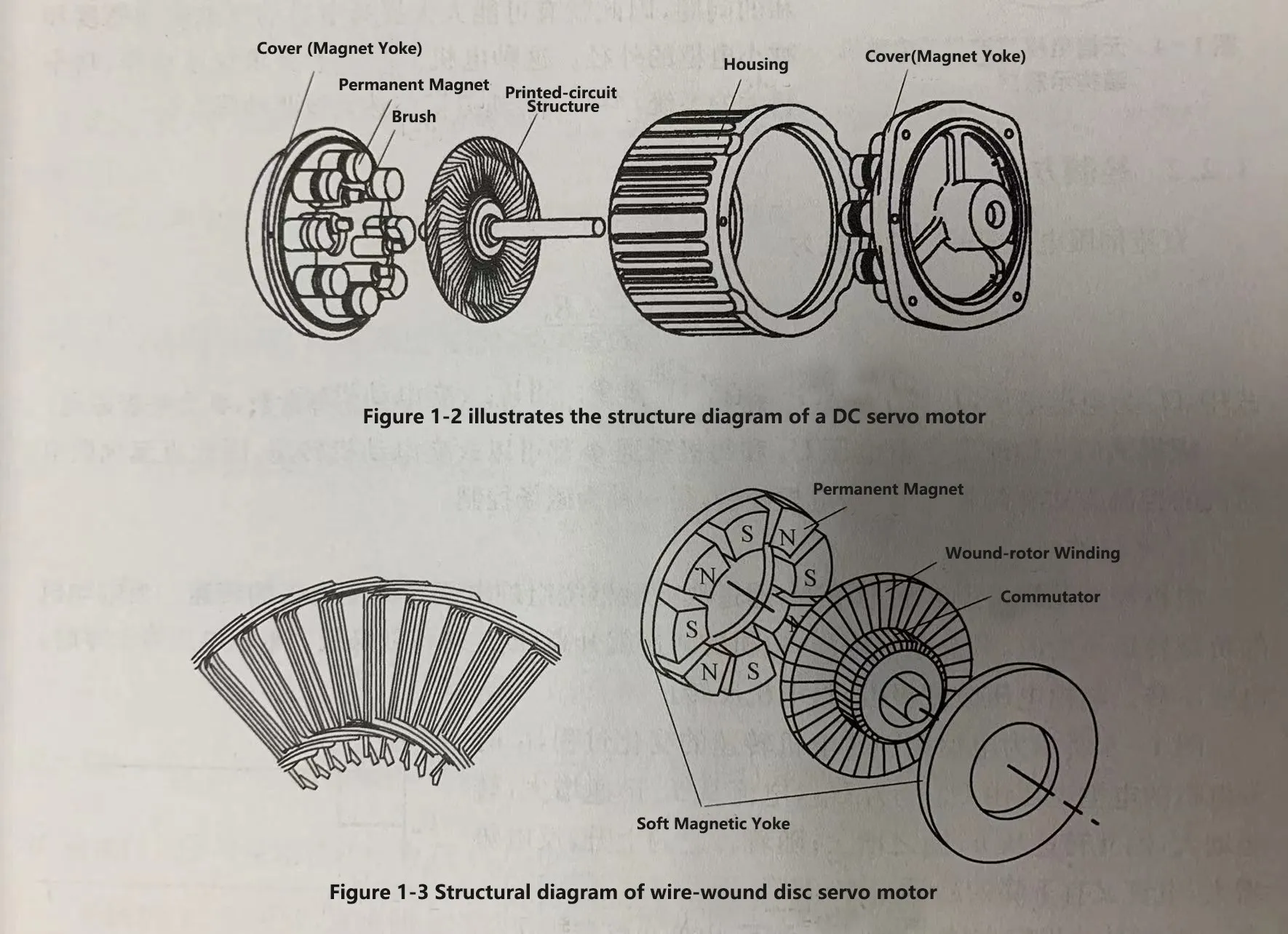

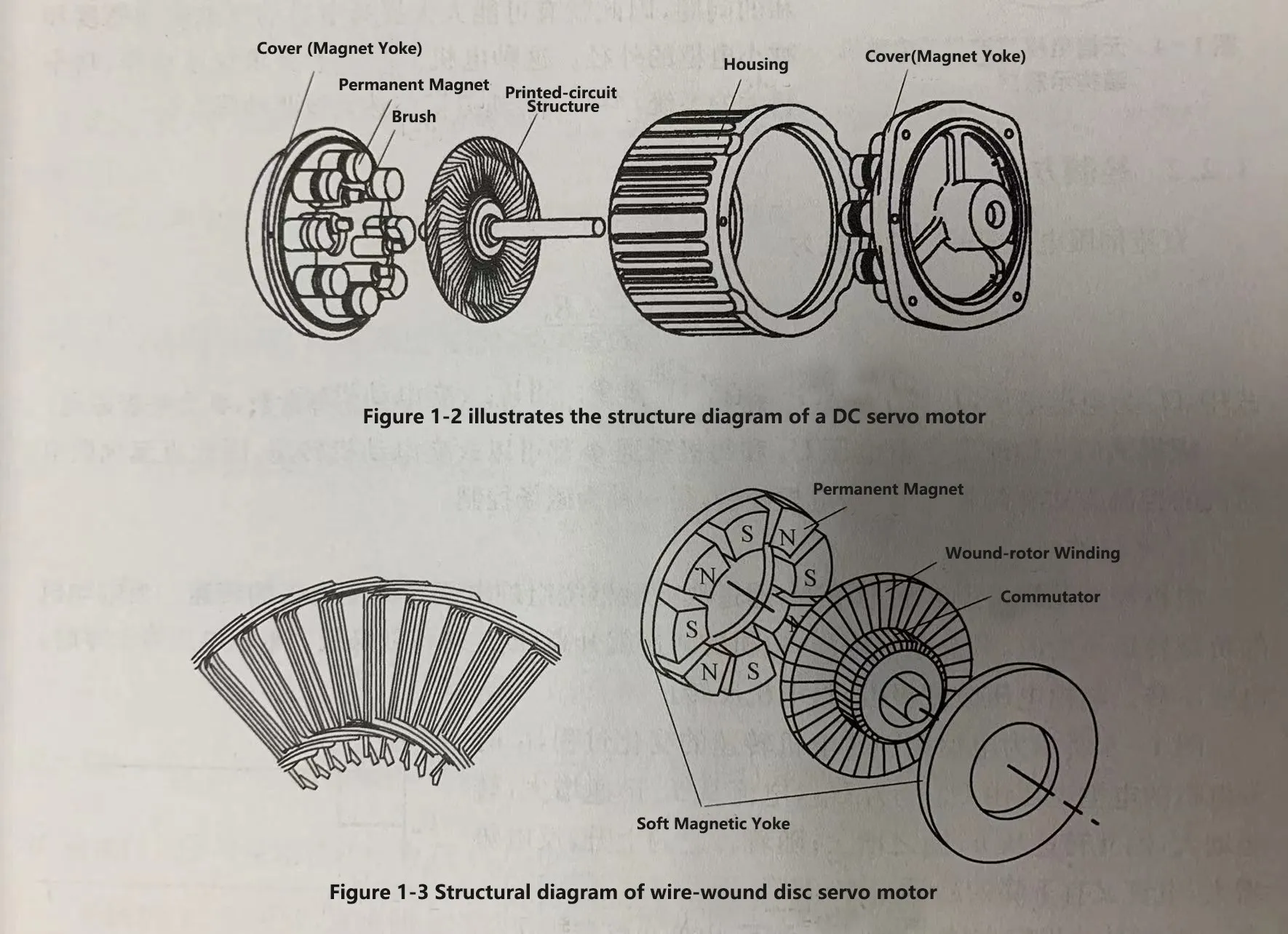

The types of DC servo motors can be divided into two categories: traditional DC servo motors and low inertia DC servo motors.  Figure 1-1 Coreless rotor DC servo motor The performance characteristics of hollow cup rotor DC servo motor are: A. Low inertia. Because the rotor has no iron core, and thin wall and slender, the inertia is very low, it is known as ultra-low inertia motor. B. High sensitivity. The good heat dissipation conditions of the rotor winding allow the current density of the winding to reach 30A/mm², and since permanent magnetic steel has a large volume, it can improve the magnetic flux density of the air gap, resulting in a large torque. In addition, the inertia is small, so the torque/inertia ratio is very large, the electromechanical time constant is very small (the minimum is below 1ms), high sensitivity, and good rapidity. The starting voltage is below 100 mV, and it is capable of completing 250 start-stop cycles per second. C. Small loss, high efficiency. The efficiency can reach 80% or higher because there is no iron consumption due to hysteresis and eddy current in the rotor. D. Torque fluctuation is small, low speed operation is smooth, noise is small. Because the winding is evenly distributed in the air gap, there is no cogging effect, so the torque transmission is uniform and the fluctuation is small, so the noise is small during operation and the low speed operation is stable. E. Good commutation performance, long life. As the cup armature lacks a core, the commutation element inductance is very small, almost no electric sparks are generated, and the commutation performance is good, thereby extending the motor's service life. This type of DC servo motor has a high manufacturing cost and is primarily used in high-precision automatic control systems and measurement devices, such as TV cameras, tape recorders, X-Y function recorders, machine tool control systems, etc. 2) Introduction of disc armature DC servo motor The characteristics of the disc armature are that the diameter of the armature is much larger than the length, the conductor of the armature is arranged along the radial direction, and the air gap between the stator and the rotor is the axial plane air gap, which facilitates the flow of magnetic flux along the axial direction, and where permanent magnetic steel is normally used for excitation. In the disc, the armature winding can be printed or winding. The latter has a greater power than the former. Printed windings are produced using a similar process to that used for printed circuit boards, which can be single double-sided or multiple overlapping pieces. The windings are first wound into a single coil, and then all the coils are arranged into a disc shape, and then thermally cured with epoxy resin. The figure 1-2 illustrates the structure diagram of a DC servo motor with printed winding disc armatures. Instead of using a commutator alone, the end of the armature close to the rotating shaft serves as the commutator, but the surface of the conductor must be coated with another layer of wear-resistant material to prolong its service life. An illustration of the winding disc servo motor structure is shown in figure 1-3.

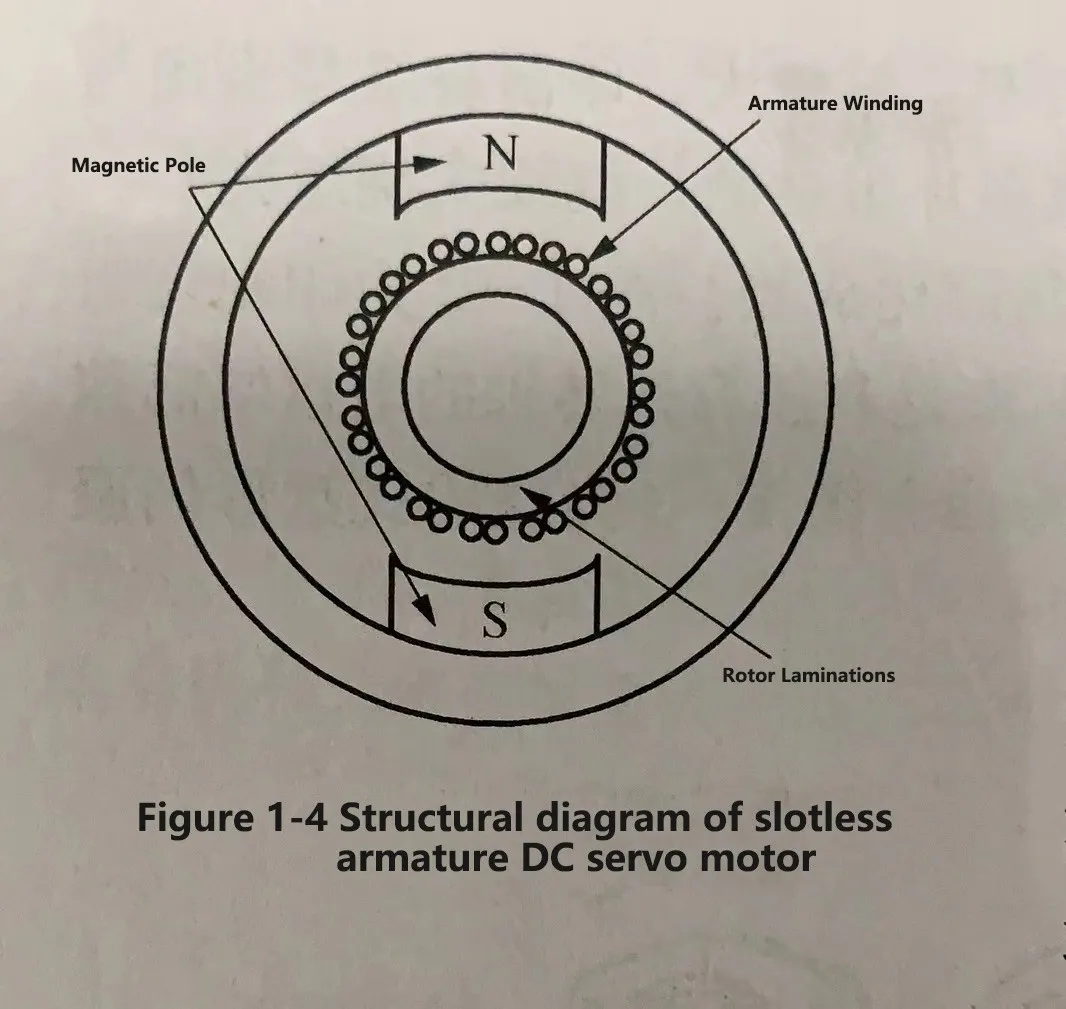

Figure 1-1 Coreless rotor DC servo motor The performance characteristics of hollow cup rotor DC servo motor are: A. Low inertia. Because the rotor has no iron core, and thin wall and slender, the inertia is very low, it is known as ultra-low inertia motor. B. High sensitivity. The good heat dissipation conditions of the rotor winding allow the current density of the winding to reach 30A/mm², and since permanent magnetic steel has a large volume, it can improve the magnetic flux density of the air gap, resulting in a large torque. In addition, the inertia is small, so the torque/inertia ratio is very large, the electromechanical time constant is very small (the minimum is below 1ms), high sensitivity, and good rapidity. The starting voltage is below 100 mV, and it is capable of completing 250 start-stop cycles per second. C. Small loss, high efficiency. The efficiency can reach 80% or higher because there is no iron consumption due to hysteresis and eddy current in the rotor. D. Torque fluctuation is small, low speed operation is smooth, noise is small. Because the winding is evenly distributed in the air gap, there is no cogging effect, so the torque transmission is uniform and the fluctuation is small, so the noise is small during operation and the low speed operation is stable. E. Good commutation performance, long life. As the cup armature lacks a core, the commutation element inductance is very small, almost no electric sparks are generated, and the commutation performance is good, thereby extending the motor's service life. This type of DC servo motor has a high manufacturing cost and is primarily used in high-precision automatic control systems and measurement devices, such as TV cameras, tape recorders, X-Y function recorders, machine tool control systems, etc. 2) Introduction of disc armature DC servo motor The characteristics of the disc armature are that the diameter of the armature is much larger than the length, the conductor of the armature is arranged along the radial direction, and the air gap between the stator and the rotor is the axial plane air gap, which facilitates the flow of magnetic flux along the axial direction, and where permanent magnetic steel is normally used for excitation. In the disc, the armature winding can be printed or winding. The latter has a greater power than the former. Printed windings are produced using a similar process to that used for printed circuit boards, which can be single double-sided or multiple overlapping pieces. The windings are first wound into a single coil, and then all the coils are arranged into a disc shape, and then thermally cured with epoxy resin. The figure 1-2 illustrates the structure diagram of a DC servo motor with printed winding disc armatures. Instead of using a commutator alone, the end of the armature close to the rotating shaft serves as the commutator, but the surface of the conductor must be coated with another layer of wear-resistant material to prolong its service life. An illustration of the winding disc servo motor structure is shown in figure 1-3.  Figure 1-3 Structural diagram of wire-wound disc servo motor The disc armature DC servo motor has similar performance characteristics to the cup armature, which is described as follows: A. The motor structure is simple, low manufacturing cost. B. Large starting torque. Because the armature windings are all in the air gap, the heat dissipation is good, and the winding current density is more than 10 times higher than that of the general DC servo motor, so the allowable starting current is large, and the starting torque is also large. C. Torque fluctuation is very small, low speed operation is stable, speed range is wide and smooth, can run reliably and smoothly in the speed ratio range of 1:20. This is mainly due to the lack of cogging effect of this motor, and the number of armature elements and commutation pieces. D. Good reversing performance. The armature is composed of non-magnetic materials, and the commutator element has a small inductance, so the commutator spark is small. E. Armature rotational inertia is small, fast response, electromechanical time constant is generally 10~15ms, belongs to the medium low inertia servo motor. 3) Introduction of slotless armature DC servo motor The slotless armature DC motor differs from the ordinary DC motor only in that the armature core is a smooth, slotless cylinder. As part of the manufacture of an armature, the winding laid on the surface of the smooth armature core is solidified with epoxy resin and bonded to the iron core. The winding has a large air gap, which is more than 10 times that of an ordinary DC motor. The stator is generally excited by permanent magnetic steel with high magnetic energy.

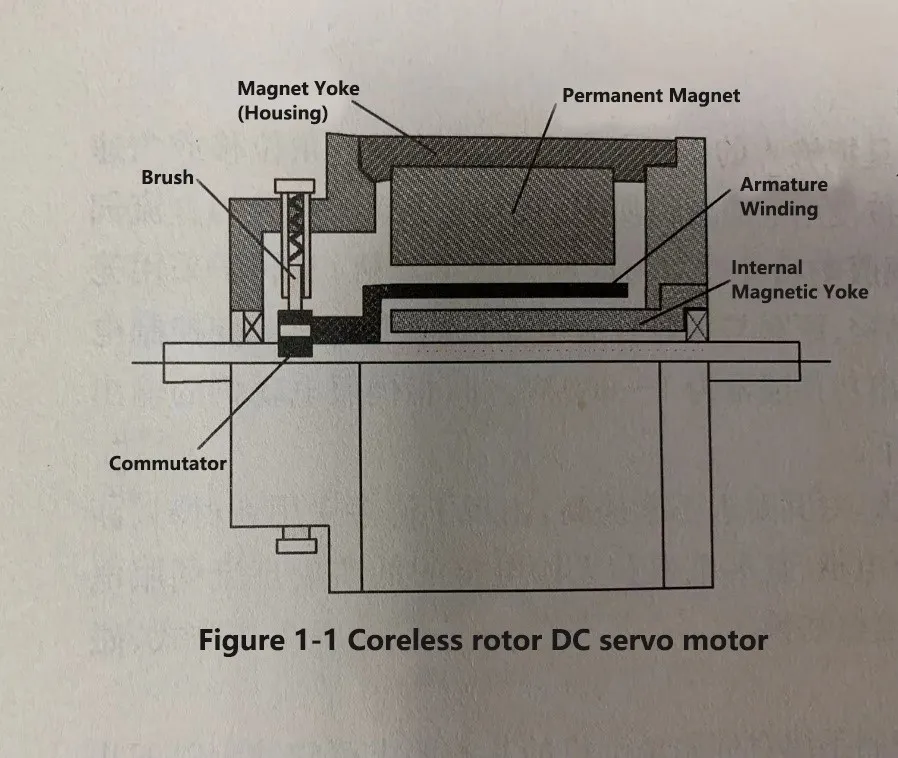

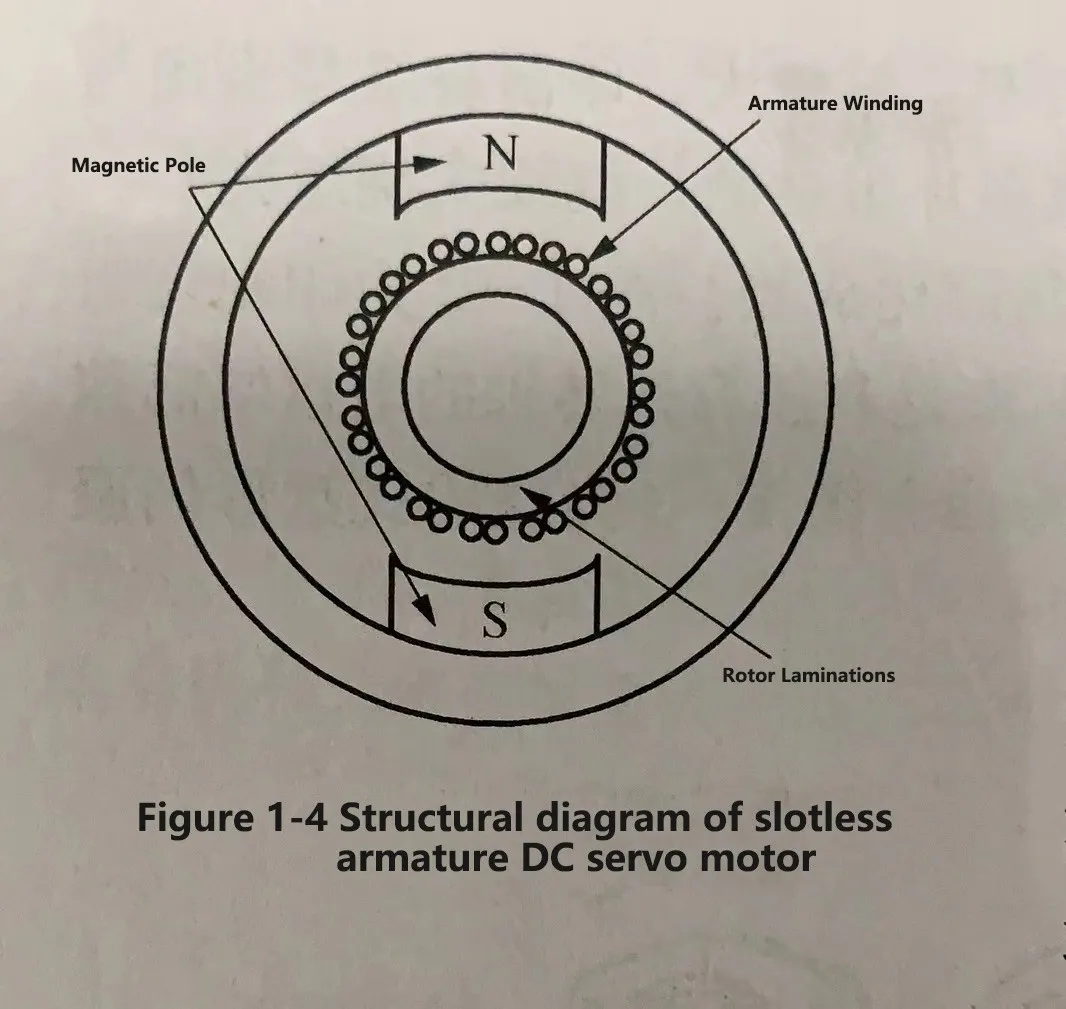

Figure 1-3 Structural diagram of wire-wound disc servo motor The disc armature DC servo motor has similar performance characteristics to the cup armature, which is described as follows: A. The motor structure is simple, low manufacturing cost. B. Large starting torque. Because the armature windings are all in the air gap, the heat dissipation is good, and the winding current density is more than 10 times higher than that of the general DC servo motor, so the allowable starting current is large, and the starting torque is also large. C. Torque fluctuation is very small, low speed operation is stable, speed range is wide and smooth, can run reliably and smoothly in the speed ratio range of 1:20. This is mainly due to the lack of cogging effect of this motor, and the number of armature elements and commutation pieces. D. Good reversing performance. The armature is composed of non-magnetic materials, and the commutator element has a small inductance, so the commutator spark is small. E. Armature rotational inertia is small, fast response, electromechanical time constant is generally 10~15ms, belongs to the medium low inertia servo motor. 3) Introduction of slotless armature DC servo motor The slotless armature DC motor differs from the ordinary DC motor only in that the armature core is a smooth, slotless cylinder. As part of the manufacture of an armature, the winding laid on the surface of the smooth armature core is solidified with epoxy resin and bonded to the iron core. The winding has a large air gap, which is more than 10 times that of an ordinary DC motor. The stator is generally excited by permanent magnetic steel with high magnetic energy.  Figure 1-4 Structural diagram of slotless armature DC servo motor As the slotless DC motor does not suffer from tooth flux density saturation, the air gap flux density can be increased greatly and the outer diameter of the armature can be reduced. Slotless armature DC motors are mainly used in systems requiring fast action and high power, such as CNC machine tools and radar antenna drive.

Figure 1-4 Structural diagram of slotless armature DC servo motor As the slotless DC motor does not suffer from tooth flux density saturation, the air gap flux density can be increased greatly and the outer diameter of the armature can be reduced. Slotless armature DC motors are mainly used in systems requiring fast action and high power, such as CNC machine tools and radar antenna drive.

1. Introduction of traditional DC servo motor

The structure of traditional DC servo motor is basically the same as that of ordinary DC motor, which is also composed of two parts: stator and rotor, but its capacity and volume are small. The traditional DC servo motor can be divided into permanent magnet DC servo motors and electromagnetic DC servo motors according to their excitation modes. Typically, the stator pole of a permanent magnet DC servo motor is constructed of permanent magnet steel, whereas the stator pole of an electromagnetic DC servo motor is typically constructed of silicon steel sheet iron core and excitation windings. The rotor structure of these two types of motors is the same as that of an ordinary DC motor, and the iron core is made from silicon steel sheets. Cogs are arranged uniformly around the outer circumference of the rotor sheet, and the armature winding is positioned in the groove and connected to the external circuit through the commutator and brush.2. Introduction of low inertia DC servo motor

As compared to a traditional DC servo motor, the low inertia DC servo motor has a small time constant and a fast response time. Currently, the low inertia DC servo motors primarily include hollow cup rotor DC servo motors, disc armature DC servo motors, and slotless armature DC servo motors. 1) Introduction of hollow cup rotor DC servo motor Figure 1-1 illustrates the structure diagram of a hollow cup rotor DC servo motor. A hollow cup rotor can be formed by winding a single coil in advance, arranging it along the cylindrical surface, or directly winding a wire cup by winding a machine, and then curing the wire with epoxy resin. The windings can also be printed. There are two stators inside and outside, the outer stator is made of permanent magnetic steel, and the inner stator is made of soft magnetic materials. A hollow cup armature is directly mounted on the motor shaft, which rotates in the air gap between the inner and outer stators. By connecting the end side of the armature winding to the commutator, the electrical connection is made to the external circuit via the brush. As a result of the need for an adequate air gap both inside and outside the rotor, there is a high reluctance and a low utilization of magnetic potential. The magnetic pole of a permanent magnet is usually made of a material that has a high magnetic energy. Figure 1-1 Coreless rotor DC servo motor The performance characteristics of hollow cup rotor DC servo motor are: A. Low inertia. Because the rotor has no iron core, and thin wall and slender, the inertia is very low, it is known as ultra-low inertia motor. B. High sensitivity. The good heat dissipation conditions of the rotor winding allow the current density of the winding to reach 30A/mm², and since permanent magnetic steel has a large volume, it can improve the magnetic flux density of the air gap, resulting in a large torque. In addition, the inertia is small, so the torque/inertia ratio is very large, the electromechanical time constant is very small (the minimum is below 1ms), high sensitivity, and good rapidity. The starting voltage is below 100 mV, and it is capable of completing 250 start-stop cycles per second. C. Small loss, high efficiency. The efficiency can reach 80% or higher because there is no iron consumption due to hysteresis and eddy current in the rotor. D. Torque fluctuation is small, low speed operation is smooth, noise is small. Because the winding is evenly distributed in the air gap, there is no cogging effect, so the torque transmission is uniform and the fluctuation is small, so the noise is small during operation and the low speed operation is stable. E. Good commutation performance, long life. As the cup armature lacks a core, the commutation element inductance is very small, almost no electric sparks are generated, and the commutation performance is good, thereby extending the motor's service life. This type of DC servo motor has a high manufacturing cost and is primarily used in high-precision automatic control systems and measurement devices, such as TV cameras, tape recorders, X-Y function recorders, machine tool control systems, etc. 2) Introduction of disc armature DC servo motor The characteristics of the disc armature are that the diameter of the armature is much larger than the length, the conductor of the armature is arranged along the radial direction, and the air gap between the stator and the rotor is the axial plane air gap, which facilitates the flow of magnetic flux along the axial direction, and where permanent magnetic steel is normally used for excitation. In the disc, the armature winding can be printed or winding. The latter has a greater power than the former. Printed windings are produced using a similar process to that used for printed circuit boards, which can be single double-sided or multiple overlapping pieces. The windings are first wound into a single coil, and then all the coils are arranged into a disc shape, and then thermally cured with epoxy resin. The figure 1-2 illustrates the structure diagram of a DC servo motor with printed winding disc armatures. Instead of using a commutator alone, the end of the armature close to the rotating shaft serves as the commutator, but the surface of the conductor must be coated with another layer of wear-resistant material to prolong its service life. An illustration of the winding disc servo motor structure is shown in figure 1-3.

Figure 1-1 Coreless rotor DC servo motor The performance characteristics of hollow cup rotor DC servo motor are: A. Low inertia. Because the rotor has no iron core, and thin wall and slender, the inertia is very low, it is known as ultra-low inertia motor. B. High sensitivity. The good heat dissipation conditions of the rotor winding allow the current density of the winding to reach 30A/mm², and since permanent magnetic steel has a large volume, it can improve the magnetic flux density of the air gap, resulting in a large torque. In addition, the inertia is small, so the torque/inertia ratio is very large, the electromechanical time constant is very small (the minimum is below 1ms), high sensitivity, and good rapidity. The starting voltage is below 100 mV, and it is capable of completing 250 start-stop cycles per second. C. Small loss, high efficiency. The efficiency can reach 80% or higher because there is no iron consumption due to hysteresis and eddy current in the rotor. D. Torque fluctuation is small, low speed operation is smooth, noise is small. Because the winding is evenly distributed in the air gap, there is no cogging effect, so the torque transmission is uniform and the fluctuation is small, so the noise is small during operation and the low speed operation is stable. E. Good commutation performance, long life. As the cup armature lacks a core, the commutation element inductance is very small, almost no electric sparks are generated, and the commutation performance is good, thereby extending the motor's service life. This type of DC servo motor has a high manufacturing cost and is primarily used in high-precision automatic control systems and measurement devices, such as TV cameras, tape recorders, X-Y function recorders, machine tool control systems, etc. 2) Introduction of disc armature DC servo motor The characteristics of the disc armature are that the diameter of the armature is much larger than the length, the conductor of the armature is arranged along the radial direction, and the air gap between the stator and the rotor is the axial plane air gap, which facilitates the flow of magnetic flux along the axial direction, and where permanent magnetic steel is normally used for excitation. In the disc, the armature winding can be printed or winding. The latter has a greater power than the former. Printed windings are produced using a similar process to that used for printed circuit boards, which can be single double-sided or multiple overlapping pieces. The windings are first wound into a single coil, and then all the coils are arranged into a disc shape, and then thermally cured with epoxy resin. The figure 1-2 illustrates the structure diagram of a DC servo motor with printed winding disc armatures. Instead of using a commutator alone, the end of the armature close to the rotating shaft serves as the commutator, but the surface of the conductor must be coated with another layer of wear-resistant material to prolong its service life. An illustration of the winding disc servo motor structure is shown in figure 1-3.  Figure 1-3 Structural diagram of wire-wound disc servo motor The disc armature DC servo motor has similar performance characteristics to the cup armature, which is described as follows: A. The motor structure is simple, low manufacturing cost. B. Large starting torque. Because the armature windings are all in the air gap, the heat dissipation is good, and the winding current density is more than 10 times higher than that of the general DC servo motor, so the allowable starting current is large, and the starting torque is also large. C. Torque fluctuation is very small, low speed operation is stable, speed range is wide and smooth, can run reliably and smoothly in the speed ratio range of 1:20. This is mainly due to the lack of cogging effect of this motor, and the number of armature elements and commutation pieces. D. Good reversing performance. The armature is composed of non-magnetic materials, and the commutator element has a small inductance, so the commutator spark is small. E. Armature rotational inertia is small, fast response, electromechanical time constant is generally 10~15ms, belongs to the medium low inertia servo motor. 3) Introduction of slotless armature DC servo motor The slotless armature DC motor differs from the ordinary DC motor only in that the armature core is a smooth, slotless cylinder. As part of the manufacture of an armature, the winding laid on the surface of the smooth armature core is solidified with epoxy resin and bonded to the iron core. The winding has a large air gap, which is more than 10 times that of an ordinary DC motor. The stator is generally excited by permanent magnetic steel with high magnetic energy.

Figure 1-3 Structural diagram of wire-wound disc servo motor The disc armature DC servo motor has similar performance characteristics to the cup armature, which is described as follows: A. The motor structure is simple, low manufacturing cost. B. Large starting torque. Because the armature windings are all in the air gap, the heat dissipation is good, and the winding current density is more than 10 times higher than that of the general DC servo motor, so the allowable starting current is large, and the starting torque is also large. C. Torque fluctuation is very small, low speed operation is stable, speed range is wide and smooth, can run reliably and smoothly in the speed ratio range of 1:20. This is mainly due to the lack of cogging effect of this motor, and the number of armature elements and commutation pieces. D. Good reversing performance. The armature is composed of non-magnetic materials, and the commutator element has a small inductance, so the commutator spark is small. E. Armature rotational inertia is small, fast response, electromechanical time constant is generally 10~15ms, belongs to the medium low inertia servo motor. 3) Introduction of slotless armature DC servo motor The slotless armature DC motor differs from the ordinary DC motor only in that the armature core is a smooth, slotless cylinder. As part of the manufacture of an armature, the winding laid on the surface of the smooth armature core is solidified with epoxy resin and bonded to the iron core. The winding has a large air gap, which is more than 10 times that of an ordinary DC motor. The stator is generally excited by permanent magnetic steel with high magnetic energy.  Figure 1-4 Structural diagram of slotless armature DC servo motor As the slotless DC motor does not suffer from tooth flux density saturation, the air gap flux density can be increased greatly and the outer diameter of the armature can be reduced. Slotless armature DC motors are mainly used in systems requiring fast action and high power, such as CNC machine tools and radar antenna drive.

Figure 1-4 Structural diagram of slotless armature DC servo motor As the slotless DC motor does not suffer from tooth flux density saturation, the air gap flux density can be increased greatly and the outer diameter of the armature can be reduced. Slotless armature DC motors are mainly used in systems requiring fast action and high power, such as CNC machine tools and radar antenna drive.