4118 Series

High Torque Stepper Motor

Frame Size: NEMA 17 | Step Angle: 1.8° • More torque than standard NEMA 17 stepper motors

• Custom wound for high speed or low speed applications

• Up to 115 oz-in (0.81 N-m) Holding Torque Contact Us for More

Unbeatable Value

The 4118 Series stepper motor is our best-selling stepper motor for numerous reasons: it delivers unbeatable balance between high performance and low price; it offers a high range of customizations; and its wide performance range makes it ideal for many applications.

Versatile performance

The 4118 Series stepper motor is a good fit for wide range of applications. The series is available in many stator lengths, from 1.34" (34mm) to 2.34" (59.4mm). Holding torque ranges from 44 oz-in (0.3 Nm), up to 115 oz-in (0.88 Nm). High range of dynamic torque with speed up to 1200 RPM. And a large selection of windings to meet your specific requirements.

Lin Engineering Quality

| Every component and every motor that leaves our facility must meet our mean value control. Additionally, every motor is tested to meet the required electrical specifications (resistance, inductance, leakage), torque specifications (holding and detent torque), mechanical specification (front shaft extension dimension and overall body length), and any other special feature specification. We want to ensure that your motor delivers the precise specifications you require. This gives you confidence that your motors will perform consistently and reliably within your application. |  |

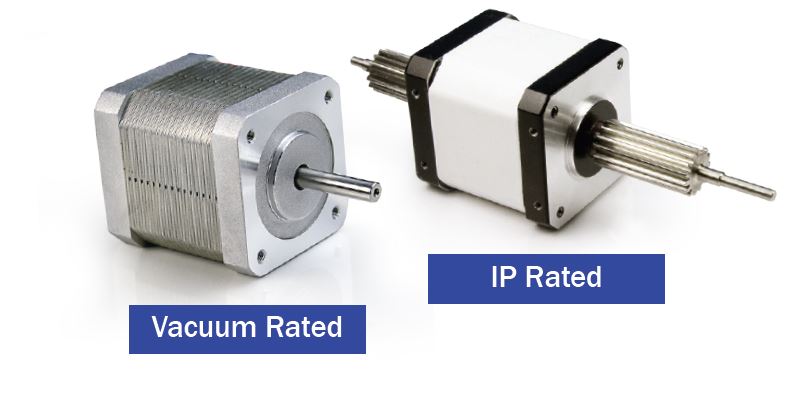

Special configuration available

| Vacuum Rating – Perfect for environments where outgassing needs to be avoided. Most commonly used in cleanrooms and vacuum chambers, and space applications. These motors are rated to perform in vacuum up to 10-7 Torr at up to 125°C. IP rating – Protection for dust, moisture, water, and other contaminates. The motor is available in IP65 and IPX7 ratings. Perfect for food production applications, where wash-down is needed. Or aerospace applications where motor is exposed to harsh atmospheric conditions. High & Low temperature operation – Motors can be configured and optimized for high temperature operation in environments up to 110 degrees C (230 F), or cold operation up to -50 degrees C (-58 F). |  |

Video Preview

Applications

|  |  |

| Medical-liquid handling and robotics | 3D printing | Blood analysis |

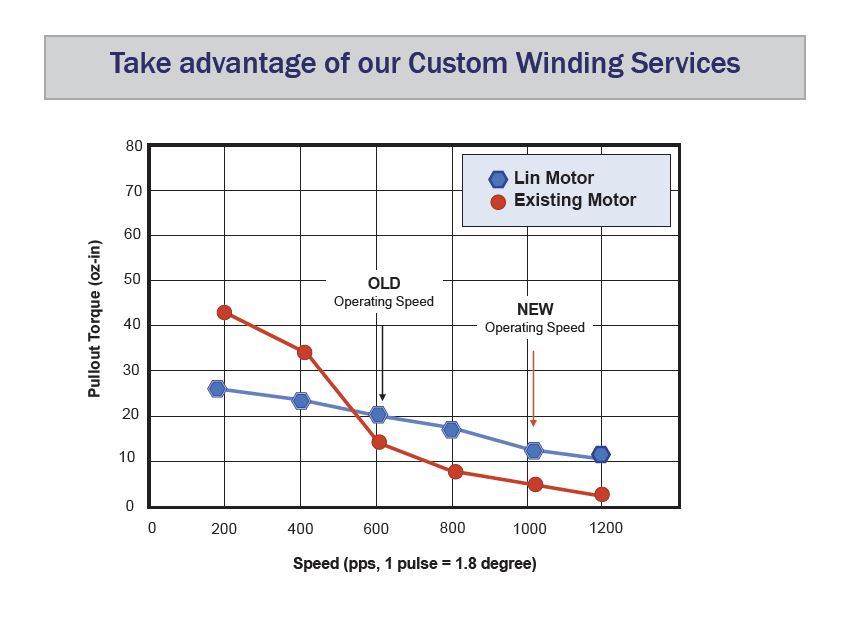

Customization Available

|  |  |  |

| Custom Windings We can customize the winding of your motor to deliver optimal torque and performance at a desired operating speed. By manipulating the winding of the motor, we can extend the dynamic torque range, minimize resonance (vibration), and optimize the efficiency of the motor. | Leads and Connectors We offer a wide variety of options that range from simple connectors to EMI protected and IP protected wiring and connectors as well. We can customize the leads and connectors in many ways. | Various Shaft Options With in-house machining capabilities, we're able to provide a variety of shaft options at a cost effective price with minimal lead times. The most common request is for a double shaft configuration. The Shafts can be cross drilled, slotted, keyed, or geared. | Encoder 4118 stepper motor can be paired with an encoder. We can provide a motor with an encoder already installed (please check out our selection of encoders), or we can provide a motor with encoder mounting holes drilled into the body. |

About LIN ENGINEERING

LIN ENGINEERING was established in 1987, is the largest manufacturer of the 0.9 degree hybrid step motor in the World. Locates in Silicon Valley, USA where gathers top high-tech enterprises and talents, its' products are mainly applied in Medical instrumentation, high level security monitoring device, aerospace avionics, etc. In 2014, Lin Engineering manufactured 550 thousand pcs 0.9º hybrid stepper motors. June 3rd, 2015 – MOONS' acquired LIN ENGINEERING, INC. of Morgan Hill, CA, which is located in Silicon Valley, USA. It's a milestone that MOONS' will explore North America market further after the acquisition of Applied Motion Products in 2014.