* Free shipping to North America and most of Europe for orders of $100 or more

ID AK Series Step-Servo Drives

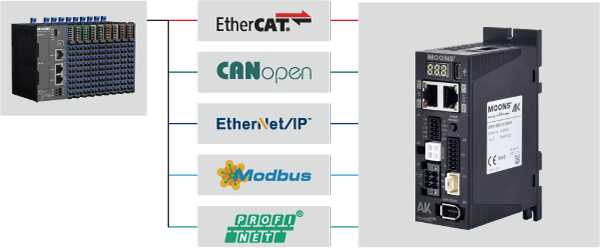

The AK series stepper servo drives provide solutions for high-precision, high-reliability automation applications. Equipped with a battery-less multi-turn absolute encoder, DIN rail mounting support, and an STO (Safe Torque Off) function for rapid torque disconnection in emergencies, ensuring safety. The drives offer excellent stability and energy efficiency, ideal for various industrial control systems. Supporting multiple industrial bus protocols, including EtherCAT, EtherNet/IP, PROFINET, RS485, and CANopen, enabling seamless integration with a wide range of devices to meet diverse application needs.

● DIN Rail mounting

● USB power-free configuration parameters

● STO functional safety

● Closed-loop stepper mode, closed-loop servo mode, open-loop mode

● Full closed-loop function

● USB power-free configuration parameters

● STO functional safety

● Closed-loop stepper mode, closed-loop servo mode, open-loop mode

● Full closed-loop function

Brand Name: MOONS'

Payment Methods

Buyer Protection:

Buyer Protection:

■ Powering Your Equipment Upgrade

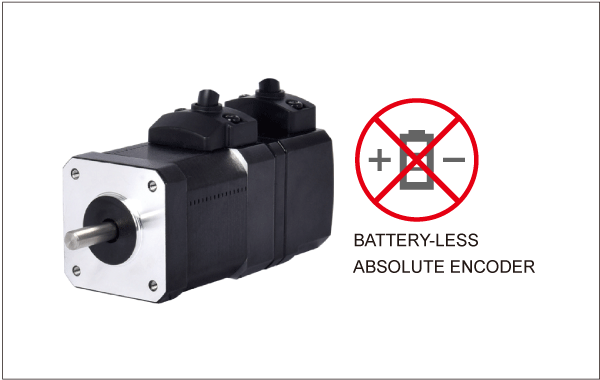

Absolute Encoder

The AK Series Step-Servo Motors utilize absolute encoder systems to optimize motor control performance, enhancing the user experience while simplifying equipment design. This allows customers to easily handle more complex applications and upgrade their equipment performance with ease.

The AK Series Step-Servo Motors utilize absolute encoder systems to optimize motor control performance, enhancing the user experience while simplifying equipment design. This allows customers to easily handle more complex applications and upgrade their equipment performance with ease.

Multi-Turn absolute encoder

With a position recording capability of over ±200,000 rotations, it is suitable for long-distance and multi-turn position recording applications.

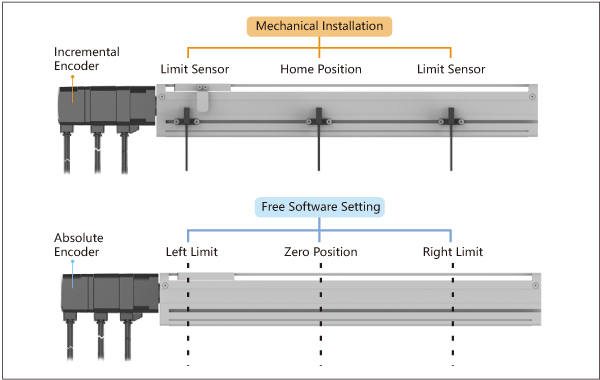

Streamlined Structure

With a built-in absolute encoder, the motor records its position in real time. This integrated approach eliminates the need for additional sensors, streamlining both the mechanical structure and cable routing.

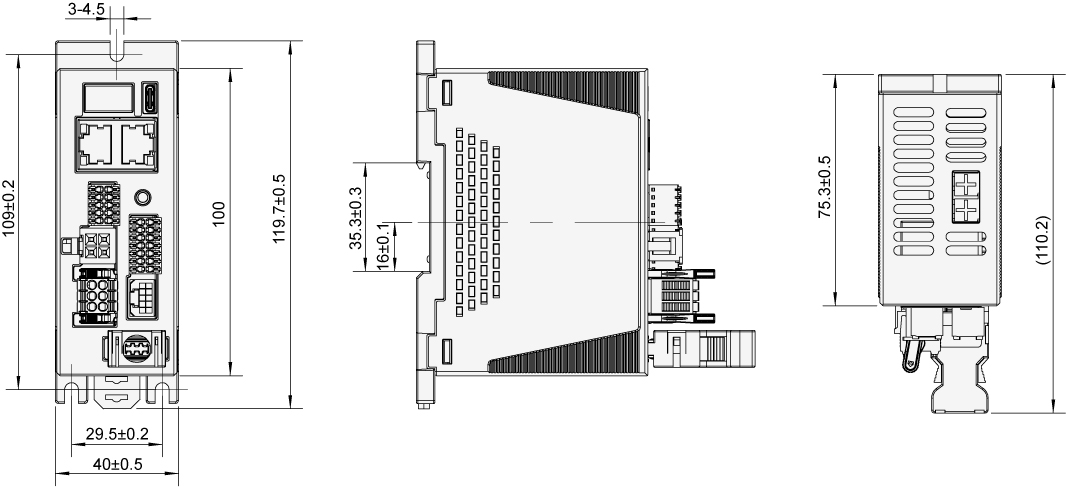

DIN Rail Mounting – Simple and Efficient

Supports both screw and DIN rail mounting. The DIN rail option allows for quick installation into electrical cabinets without tools, significantly boosting productivity.

■ Flexible Control Modes

For versatile use cases

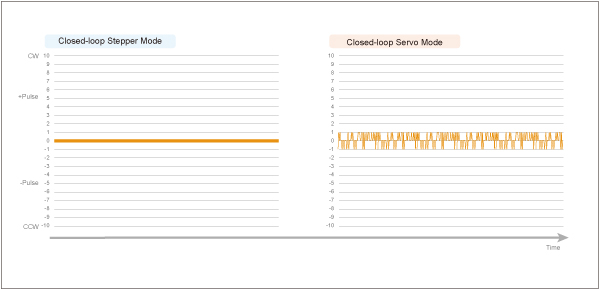

One Drive, Multiple Solutions. Engineered with a new control algorithm and hardware, this highperformance drive adapts to your needs. It operates in open-loop, closed-loop stepper, or full servo mode to master a vast array of applications.

One Drive, Multiple Solutions. Engineered with a new control algorithm and hardware, this highperformance drive adapts to your needs. It operates in open-loop, closed-loop stepper, or full servo mode to master a vast array of applications.

|

|

|

| Closed-loop Stepper control Prevents step loss and stalling No micro-motion at stop No micro-movement when stopped No need for re-tuning |

Closed-loop Servo Mode Servo control algorithm Low heat generation High dynamic response |

Open-loop Stepper Mode No encoder required Low cost Easy to use, good stability |

Closed-Loop Stepper

In closed-loop stepper mode, the motor remains securely at rest with no creeping. It automatically engages closed-loop control in response to load changes or motion to prevent step loss, making it ideal for most applications.

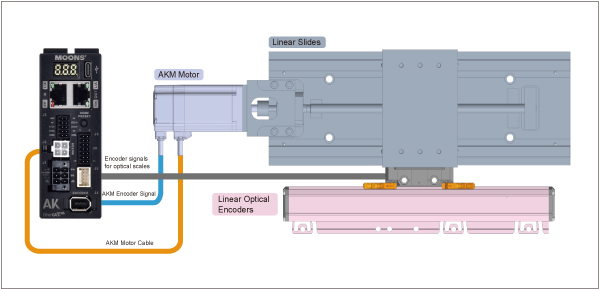

Full closed loop Control

Equipped with full-closed loop control, the system utilizes a high-precision grating scale and a secondary encoder to deliver exceptionally accurate positioning, making it ideal for applications demanding ultra-high precision.

■ Wide Compatibility with Multiple

Bus Protocols

The AK Series supports various bus protocols, allowing seamless integration with different upperlevel control systems, meeting a wide range of industrial application needs.

The AK Series supports various bus protocols, allowing seamless integration with different upperlevel control systems, meeting a wide range of industrial application needs.

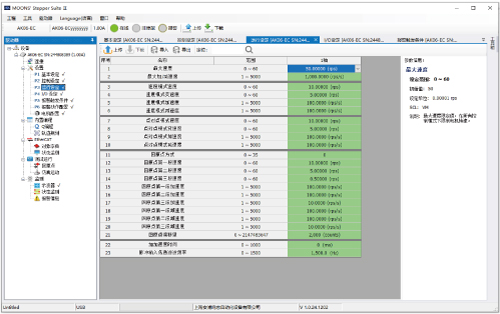

■ New Stepper Suite II software

Quick Parameter Configuration

Supports quick online/offline configuration, easily adjusting driver parameters to optimize system performance.

Real-Time Monitoring & Alarms

Built-in oscilloscope function for real-time monitoring, with graphical alarm display to quickly identify issues.

Smart Fault Diagnosis

Automatically analyzes fault codes and provides repair suggestions to quickly resolve issues and minimize downtime.。

Multi-Device Management

Supports centralized management of multiple drivers, simplifying debugging and boosting efficiency.

Data Analysis & Optimization

Graphical data display helps optimize equipment performance and improve operational efficiency.

Supports quick online/offline configuration, easily adjusting driver parameters to optimize system performance.

Real-Time Monitoring & Alarms

Built-in oscilloscope function for real-time monitoring, with graphical alarm display to quickly identify issues.

Smart Fault Diagnosis

Automatically analyzes fault codes and provides repair suggestions to quickly resolve issues and minimize downtime.。

Multi-Device Management

Supports centralized management of multiple drivers, simplifying debugging and boosting efficiency.

Data Analysis & Optimization

Graphical data display helps optimize equipment performance and improve operational efficiency.

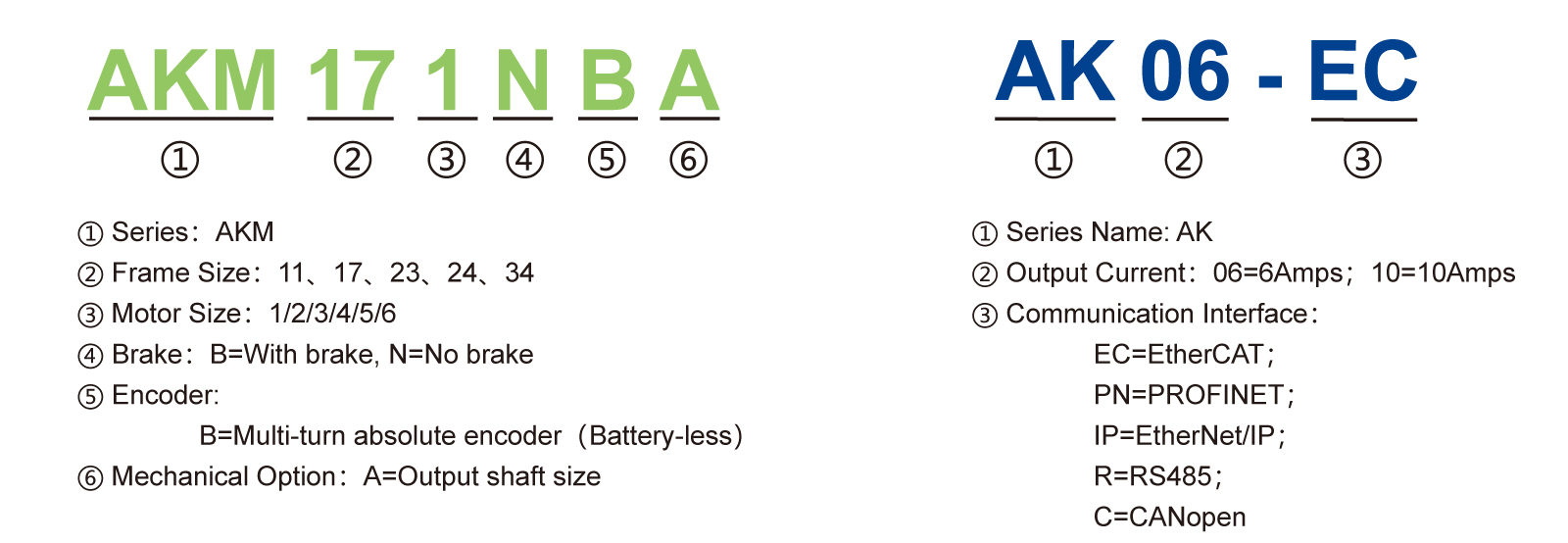

■ Numbering System

■ Drive Specification

| Power Supply | Main Power | 24-48VDC(18-53VDC) |

|---|---|---|

| Control Power | 24VDC±10% | |

| Output Current | AK06 | 6 Amps |

| AK10 | 10 Amps | |

| STO | 24VDC±10% | |

| Encoder | battery-less multi-turn absolute encoder | |

| 2st Encoder | Biss-C、T-formart、±ABZ encoder signal input | |

| 5V differential ±ABZ encoder signal output | ||

| Communication | RS485 | Modbus/RTU、Pulse control、Q program |

| EtherCAT | CoE(CSP、CSV、PP、PT、PV、HM)、FoE 功能 | |

| PROFINET | PROFIDrive | |

| EtherNet/IP | CIP service、Class1、Class3 | |

| CANopen | CiA402(PP、PV、PT、HM)、CiA301 | |

| Digital Input | 2-channel differential, photocoupler-isolated input; 5-24 VDC; 500 ns min., 1 MHz max. (at 50% duty cycle) | |

| 4-channel single-ended, photocoupler-isolated input; 5-24 VDC; 100 μs min., 5 kHz max. (at 50% duty cycle) | ||

| Digital Input | 3-channel common-cathode, photocoupler-isolated, open-collector output; 30 VDC max., 100 mA max. | |

| Brake Control Output*1 | 1-channel electromagnetic brake control; 24 VDC ±10% | |

| Communication Interface | RJ45 connector,Type-C connector | |

| Ambient Temp*2 | 0-50℃ (32-122°F) | |

| Ambient Humidity | Maz 90%、Non-condensing | |

| Installation | DIN rail mounting、Screw mounting | |

*1 When used with a brake motor, the brake is directly controlled by the driver. Please ensure the control power supply remains within the allowable voltage range of 24V ±10% for proper operation.

*2 When the ambient temperature approaches 50°C, effective cooling measures such as installing a cooling fan, adding a heat sink, or enhancing the ventilation system must be implemented. Inadequate cooling may cause the drive to overheat, compromising performance and reliability.

*2 When the ambient temperature approaches 50°C, effective cooling measures such as installing a cooling fan, adding a heat sink, or enhancing the ventilation system must be implemented. Inadequate cooling may cause the drive to overheat, compromising performance and reliability.

■ Drive Power Supply

The drive main power operates on DC. Since motors of different models and specifications have varying current and power requirements during operation, the power supply capacity must be carefully selected based on the specific motor used. To ensure stable and reliable system operation, please configure the power supply capacity according to your motor's parameters. The recommended input current for different motor combinations is provided below.

| Model | Main Power Supply Current(Amps) | Maximum power consumption(w) | |

|---|---|---|---|

| 24VDC | 48VDC | ||

| AKM11 □ BA | 1.2 | 28.8 | 57.6 |

| AKM17 □ BA | 1.4 | 33.6 | 67.2 |

| AKM24 □ BA | 4.8 | 115 | 230 |

Note: □ Indicates whether it comes with a brake.

■ Motor Specification

| Model | Drive | Torque | Encoder | Speed | Frame size |

Permissible Overhung Load(N)) Distance(L) from Shaft End(mm) |

Permissible Thrust Load (N) |

||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| N·m | 脉冲/ 圈 | rpm | mm | 0 | 5 | 10 | 15 | 20 | |||

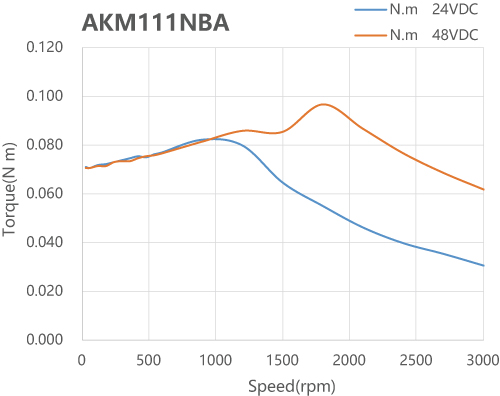

| AKM111 □ BA | AK06- ◇ | 0.06 | 10000 | 3600 | 28 | 20 | 25 | 34 | 52 | - | Less than the motor mass |

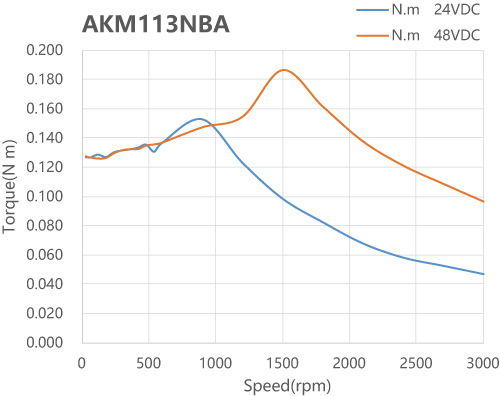

| AKM113 □ BA | 0.12 | 28 | 20 | 25 | 34 | 52 | - | ||||

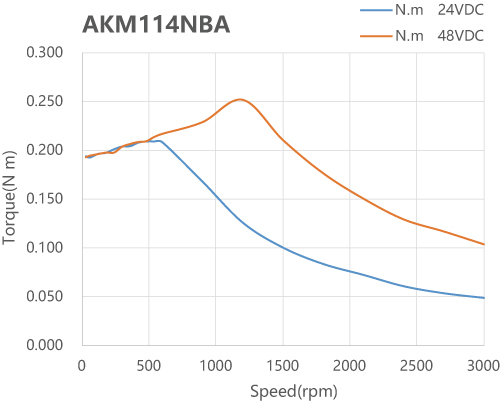

| AKM114 □ BA | 0.19 | 28 | 20 | 25 | 34 | 52 | - | ||||

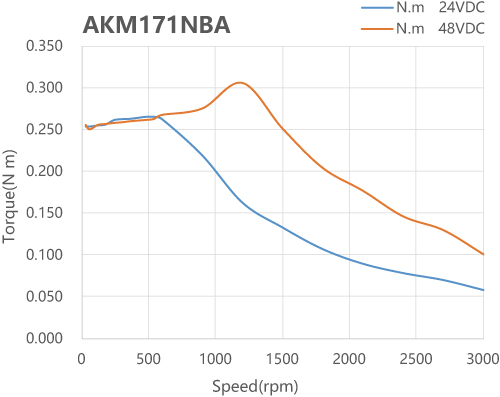

| AKM171 □ BA | 0.25 | 42 | 35 | 44 | 58 | 85 | - | ||||

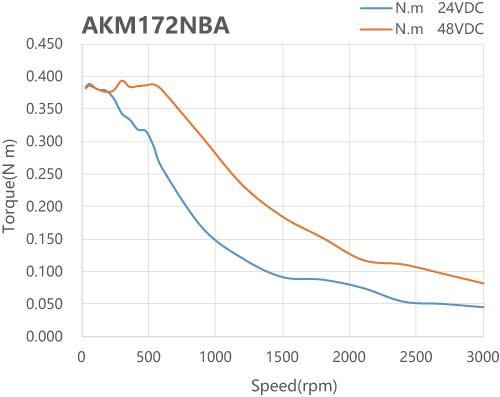

| AKM172 □ BA | 0.38 | 42 | 35 | 44 | 58 | 85 | - | ||||

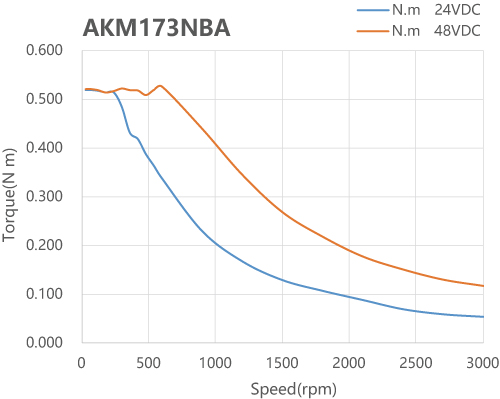

| AKM173 □ BA | 0.51 | 42 | 35 | 44 | 58 | 85 | - | ||||

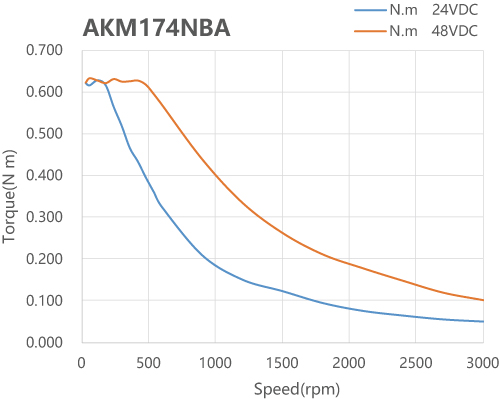

| AKM174 □ BA | 0.62 | 42 | 35 | 44 | 58 | 85 | - | ||||

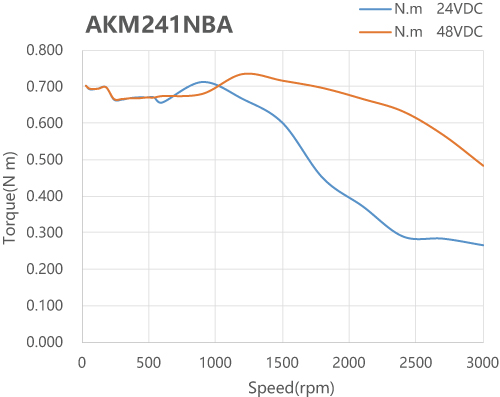

| AKM241 □ BA | 0.7 | 60 | 90 | 100 | 130 | 180 | 270 | ||||

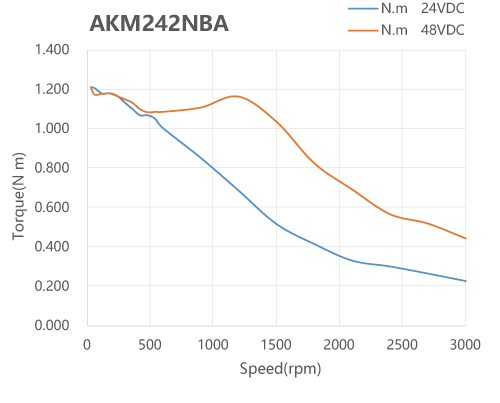

| AKM242 □ BA | 1.2 | 60 | 90 | 100 | 130 | 180 | 270 | ||||

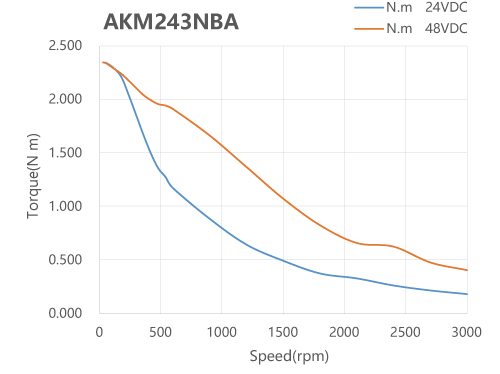

| AKM243 □ BA | 2.33 | 60 | 90 | 100 | 130 | 180 | 270 | ||||

Note:

□ Indicates whether it comes with a brake.

◇ Indicates the drive communication method.

□ Indicates whether it comes with a brake.

◇ Indicates the drive communication method.

2D Drawings

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| AK06-EC 2D.pdf | 362 | ||

| AK06-R 2D.pdf | 354 |

3D Model

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| AK06-EC 3D.stp | STEP | 26446 | |

| AK06-R 3D.stp | STEP | 26446 |

Brochure

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| AK Family Brochure_EN20251224_A1.pdf | 3492 |

User Manual

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| AK-EC User Manual_EN20251222.pdf | 5089 | ||

| AK-R User Manual_EN20251222.pdf | 3817 |

Certification

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| AK Series CE Certification.pdf | 1662 |

Software

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| AMA Step-Servo EtherCAT v3.2.9.zip | XML | 181 | |

| Stepper Suite Ⅱ Setup 1.0.25.1118.zip | ZIP | 32028 |

Filter By Product Type

All ProductsExtended Motor Cables

Communiaction Cable

Motor Types

Regen Clamp

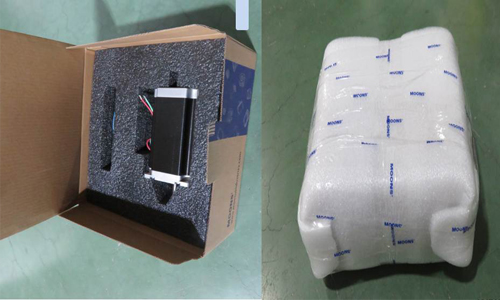

Delivery & Packaging

Ensure your ordered products are always safely packaged from easy click to fast delivery to your handsProfessional Product Label

Considering all possible harsh application environments, MOONS' specially designed labels for each product, which pass water-resistance test, durability rub test, high temperature resistance and corrosion resistance tests.Besides, our product labels are attached with QR code linking to product details, which is convenient for clients to view the detail product page with their mobile phones.

Note: This label design is suitable for products of stepper motor.

(Professional packing box and unique appearance design)

(Single item packed with EPE)

(Multi-products packed with another box)

Safely Packaging

In order to ensure your shipments withstand the long trip and arrive safely and intact, MOONS' specially designed Individual package to pass the drop test with its stable structure.Besides,the package is made from recyclable materials, providing you with professional safety delivery.

Whether just single item or multi-products the clients buy, all products are packed twice to avoid the damage further.

Shipping Visualization

For each case, products are carefully packed by experienced warehouse staff and the key processes are recorded by photos, which are then posted on our website, so that clients could clearly know the packing process and logistics status after placing order.

(Product in the box)

(Add the invoice)

(Label the commodity)

(The logistics waybill attached)

Fast Delivery

Fast Cross-Border DeliveryMOONS' chooses DHL as our main international express shipping partner. As the world's leading logistics specialist, DHL provides our customers with fast and professional inter- national door-to-door delivery service.

Estimated Delivery Time: e.g. China-USA major cities 3 business days.

Professional

Warehouse Management

Free Exchange

Free Exchange