Function introduction

Intelligent Inspection

The "XST" Intelligent Inspection System is independently developed, designed, and produced by Shanghai MOONS'. It fully addresses the management needs of equipment-intensive enterprises globally by integrating advanced IoT technologies. Combining RFID, facial recognition, vibration measurement, infrared thermography, video intercom, photo/audio recording, 4G/5G communication, and GPS/BeiDou positioning into a smart PDA, it collaborates with a software platform to digitize, intellectualize, and optimize inspection operations. This significantly enhances on-site operational and management efficiency.

Through regular inspections, potential equipment risks are identified early. Analysis of inspection data over time enables assessment of equipment degradation trends, facilitating timely maintenance and reducing failure rates.

Through regular inspections, potential equipment risks are identified early. Analysis of inspection data over time enables assessment of equipment degradation trends, facilitating timely maintenance and reducing failure rates.

Condition Monitoring & Fault Diagnosis

The Equipment Online Monitoring & Intelligent Fault Diagnosis System (DHMS) integrates next-generation IT with fault diagnosis technology to provide 24/7 online condition monitoring for industrial equipment. It delivers intelligent fault alerts, automated diagnosis and analysis, health assessments, predictive failure analysis, and hidden risk warnings. This ensures reliable and stable equipment operation, enhances workplace safety, boosts productivity, and reduces maintenance costs.

Maintenance Management

Maintenance Management spans from scheduled maintenance planning and daily work order generation to final acceptance. It covers the formulation of scheduled/annual/monthly/daily maintenance plans, work order creation, progress tracking, project acceptance, review, and performance analysis.

Standardized processes define maintenance cycles, scheduling dates, and applicability of maintenance work standards (including technical standards, standard checklists, cost quotas, material lists, and safety lockout/tagout procedures). Cost control is achieved through maintenance quotas; technical standards guide proper execution; safety protocols ensure operational security; material lists enable advance preparation of consumables/spare parts. Post-completion acceptance generates maintenance records to refine work standards and validate their effectiveness, ultimately increasing equipment uptime and reducing maintenance costs.

Standardized processes define maintenance cycles, scheduling dates, and applicability of maintenance work standards (including technical standards, standard checklists, cost quotas, material lists, and safety lockout/tagout procedures). Cost control is achieved through maintenance quotas; technical standards guide proper execution; safety protocols ensure operational security; material lists enable advance preparation of consumables/spare parts. Post-completion acceptance generates maintenance records to refine work standards and validate their effectiveness, ultimately increasing equipment uptime and reducing maintenance costs.

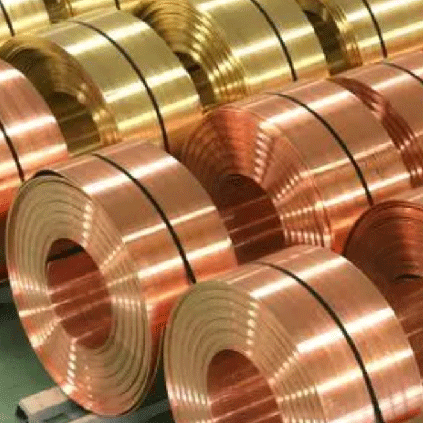

Spare Parts Management

Spare parts costs account for over 40% of equipment management expenses in asset-intensive enterprises. Controlling these costs is a critical priority for equipment managers.

The Spare Parts Management System calculates optimal inventory levels using historical consumption data, installed quantities, procurement cycles, and service life. During requisition, quantity/time/budget models automatically validate requests, strictly controlling procurement sources. Full lifecycle management of critical equipment is achieved through spare parts installation/removal, repair, and scrapping, providing data support for supplier evaluations.

The Spare Parts Management System calculates optimal inventory levels using historical consumption data, installed quantities, procurement cycles, and service life. During requisition, quantity/time/budget models automatically validate requests, strictly controlling procurement sources. Full lifecycle management of critical equipment is achieved through spare parts installation/removal, repair, and scrapping, providing data support for supplier evaluations.

Mobile Office

The Equipment Management Mobile Office is an HTML5-based App seamlessly integrated with enterprise platforms like WeChat Work and DingTalk. It enables equipment managers to access real-time equipment status and operational data via mobile devices anytime, anywhere, significantly improving work efficiency and response speed.

KPI

Foundation data and process management data (inspection, condition monitoring, maintenance, lubrication, costs) from the Equipment Asset Management System are cleaned, analyzed, and visualized through bar charts, line graphs, pie charts, and radar charts. This provides data-driven insights to support rapid decision-making for leadership.