How to Reduce the Noise & Resonances of Stepper Motors

Stepper motors have more advantages of simple structure, ease to control, high safety, low cost, high torque, etc. As a high-performance digitized electrical component, stepper motors are widely used in different types of open-loop control systems. However, the stepper motor has a disadvantage in that it has noisy at low speed. Noise and resonances mainly come from the drive circuit and the mechanical structure of resonance.

The main reason for the driving circuit noise is higher harmonic. Stepper motors are driven by square wave current, which must contain a large number of higher harmonics, thus producing vibration and noise. The SR series drives are cost-effective, high-performance step drives. The design is based on advanced digital current control technology and features high torque, low noise, and low vibration. The running current, microstrip resolution, and other parameters are switch selectable.

MOONS' Drive Circuit Resonance Solution

Features

Anti-Resonance

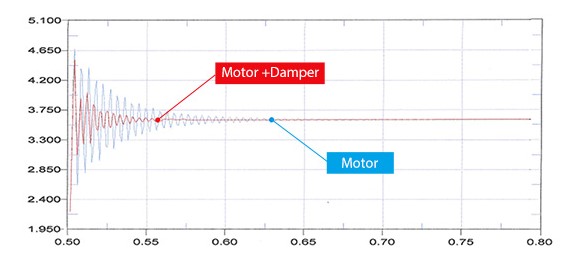

Step motor systems have a natural tendency to resonate at certain speeds.The SR drives automatically calculate the system’s natural frequency and apply damping to the control algorithm. This greatly improves midrange stability, allows higher speeds and greater torque utilization, and also improves settling times.

Provides better motor performance and higher speeds

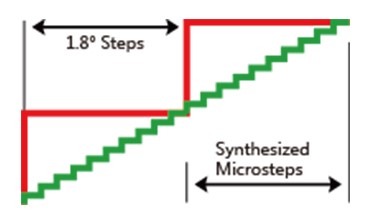

Microstep Emulation

With Microstep Emulation, low resolution systems can still provide smooth motion. The drive can take low resolution step pulses and create fine resolution motion.

Improves overall system performance

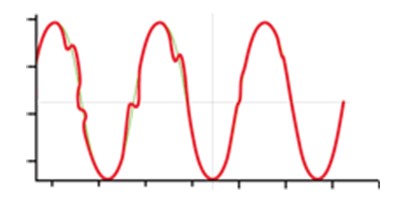

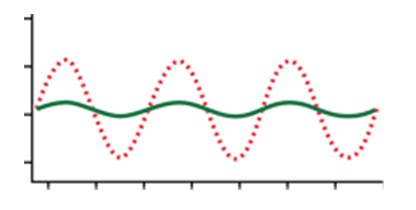

Torque Ripple Smoothing

All step motors have an inherent low speed torque ripple that can affect the motion profile of the motor. By analyzing this torque ripple the system can apply a negative harmonic to counter this effect. This gives the motor much smoother motion at low speed.

Produces smoother motion at low speeds

To accommodate the use of the feed motor in industrial control applications more widely, MOONS' also introduced the ST series step actuators with communications and the STF series step actuators.

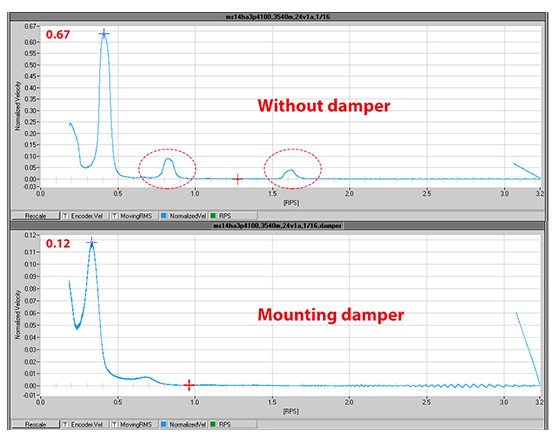

As the motor moves, the rotating part or rotor oscillates around a new position before stopping, and the time the motor oscillates is called the settling time. Vibration may not be reduced by adjusting the drive parameters without changing the overall design. In this case, the best solution is to use a damper.

Dampers are used to reduce resonances, reduce noise, and improve response time of step motor systems. They are mounted between the motor and machine, and work by reducing shock impulses and dissipating the kinetic energy in resonances.

MOONS' Mechanical Resonance Solution

Features

Anti-Resonance, less noise, and Torque Ripple Smoothing

All stepper motors have an inherent low speed torque ripple that can affect the motion of the motor. In some systems this torque ripple can cause resonances to build up at specific speeds. This causes noise and can even cause the motor to stall. The energy-absorbing rubber in MOONS' dampers absorb shock to reduce resonances and vibration. This can greatly improve system stability, eliminate noise, allow for much smoother motion at low speed, and provide greater torque utilization at higher speeds.

Fast Response

When performing fast point-to-point moves, a damper can enhance the system transient response and reduce settling time. This improves control accuracy.