Introduction to MOONS' ball screw linear motors

MOONS' BE Series products are designed on the basis of the know-how technology of hybrid stepper motors, ball screws, and nuts, which provide high torque, high precision, and high efficiency in order to meet the application needs of designers. Combining motor styles, motor sizes, ball screws, and nuts allows the use of motors of different form factors to meet the exact needs of the application. Moreover, it provides the best performance with any drive and power supply. MOONS' offers a wide range of optional configurations: multiple structure types, and multiple motor length options, Integrate any lead screw and ball nut from MOONS', standardized product models for quick response.

Product Features of Ball Screw Linear Motors

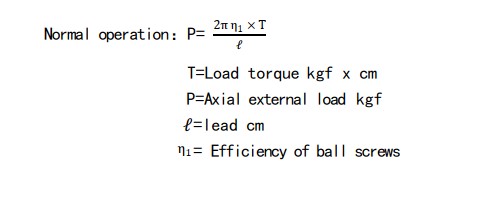

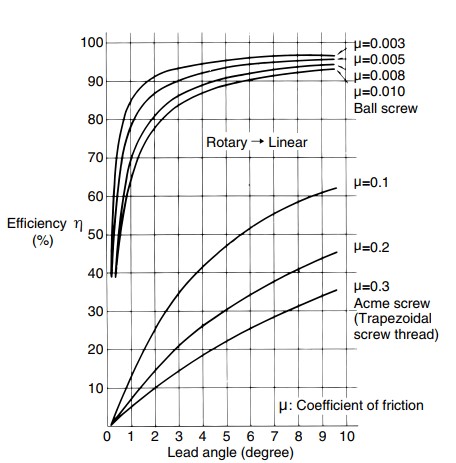

1 High mechanical efficiency: Ball screws of the BE Series have an outstanding transmission efficiency of over 90%, which is unmatched by lead screws. The torque they require is less than one-third of that required by lead screws. Consequently, it is easier to convert a linear motion into a rotary motion.

Efficiency of ball screws (Rotary → Linear)

Mechanical efficiency of ball screws

2 Small axial clearances, High accuracy, High rigidity: The ball screws of the BE Series have a gothic-arch groove profile, and their axial clearance can be adjusted with a fine pitch as well as being rotated lightly. Additionally, the axial clearance can be adjusted to 0 by applying a preload to the screw.

Ball screw groove profile

3 The BE Series connects the ball screws directly to the motors, while non-couplings offer the advantages of compactness and high universality.

4 High hardness, Excellent durability: Ball screws of the BE Series provide excellent durability due to carefully selected materials, proper heat treatment, and advanced production techniques. Generally, ball screws are manufactured to maintain a hardness of 58 HRC or higher.

Ball Screw Linear Motors Selection Guide

Applicability Statement: Due to the ball-screw drive transmission of this series, high operating frequencies and high repetition accuracy applications are recommended.

Instructions for Vertical Installation: The low friction resistance of the ball screw may result in injury to equipment and personnel if the device suddenly loses power when installed vertically. Thus, brakes should be considered when the products are used vertically.

Repeatability: This product uses a precision-grade C7 ball screw with a repetition accuracy of ± 0.01mm. Please contact the factory if you require higher-precision products.

Speed: The recommended motor rotation speed for this product is not greater than 10 revolutions per minute. Please refer to the specific series for running speed information: B Series Linear Step Motors. For linear intelligent motors, the recommended motor rotation speed is not greater than 50 revolutions per minute.

Operating Environment: We recommend that working conditions be in the range of 0°C to 50°C, under dry and clean conditions. Please contact the factory if you need to use it in a special environment.