- Home

- Technical College

- MOTOR DRIVES

- Principle of Point-to-Point Cubic Interpolation in PVT Mode for Drives

Principle of Point-to-Point Cubic Interpolation in PVT Mode for Drives

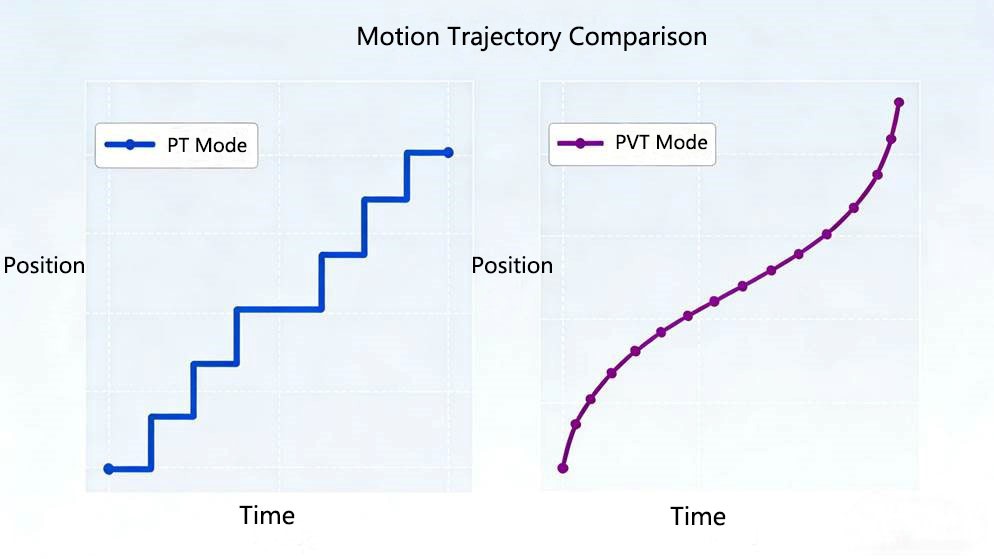

Point-to-point cubic interpolation in PVT mode, as implemented within the drive, is a trajectory planning method used to achieve high-precision and smooth motion. To fully understand this approach, it is first necessary to clarify several core concepts involved in the drive's point-to-point cubic interpolation under PVT mode.

A drive, typically referring to a servo drive or a stepper drive, is a core component of a motor motion control system. It is responsible for precisely controlling the motor's position, velocity, and acceleration based on the given command inputs.

PVT mode consists of three elements: Position, Velocity, and Time:

P (Position): the absolute position that the target object (such as a robotic arm end effector or a worktable) is required to reach at a given point in time during the motion;

V (Velocity): the instantaneous velocity at that time;

T (Time): the absolute timestamp at which the specified position–velocity state is reached.

Essentially, PVT is a trajectory pre-planned control mode. Users do not need to manage the detailed acceleration or deceleration profiles inside the drive; instead, they only need to provide the drive with a set of desired positions and velocities at specified future time instants—forming a series of trajectory "waypoints". Based on these PVT points, the drive automatically computes a continuous and smooth motion trajectory and controls the motor to follow it precisely.

Point-to-point motion refers to a motion task in which the system moves directly from a starting position (Point A) to a target position (Point B), typically without requiring the motion to pass through any specified intermediate path points.

Cubic interpolation is a key method for trajectory generation. Interpolation refers to the process of generating a continuous and smooth trajectory between known discrete PVT waypoints using a mathematical model—that is, constructing time-dependent functions of position, velocity, and acceleration. The term "order" denotes the highest degree of the mathematical function used for interpolation. In cubic interpolation, a third-degree polynomial is typically employed to interpolate the position. The motion characteristics associated with different interpolation orders are summarized as follows:

First-order interpolation (linear): Position is a linear function of time, velocity remains constant, acceleration is zero, and the system experiences significant impact during start-up and stopping.

Second-order interpolation (parabolic): Position is a quadratic function of time, velocity changes linearly, and acceleration is constant. However, abrupt changes in acceleration occur at the start and end of motion, causing the jerk to approach infinity, so the motion smoothness is still insufficient.

Third-order interpolation (cubic): Position is a cubic function of time, velocity is a quadratic function, acceleration is linear, and the jerk remains constant, resulting in smooth and continuous motion.

The main advantage of cubic interpolation is that it ensures continuity of the trajectory in terms of both position and velocity, while maintaining smooth acceleration without abrupt changes. This characteristic can significantly reduce mechanical vibration and shock, improve motion control accuracy, and contribute to extending the service life of both mechanical systems and drives.

Bringing together the concepts described above, "point-to-point cubic interpolation under PVT mode" can be understood in terms of its meaning and implementation process.

The objective of the motion is to smoothly move the device from the starting position Pstart to the target position Pend, while ensuring continuity and smoothness throughout the trajectory. The implementation procedure can be summarized in the following steps:

The first step is to plan the PVT points. Although the motion is point-to-point, at least two PVT points are required to generate a smooth cubic trajectory: a start point and an end point. Additional intermediate PVT points can be added for more complex paths or when stricter requirements are imposed on the motion characteristics.

• Starting PVT point: Time T = T0, position P = Pstart, velocity V = 0 (assuming the system starts from rest);

• Ending PVT point: Time T = T0 + Ttotal, position P = Pend, velocity V = 0 (assuming the system comes to a complete stop at the end point).

Next, the drive performs cubic interpolation. Upon receiving the PVT points described above, the drive automatically computes a unique trajectory in the form of a cubic polynomial. This trajectory must strictly pass through both the starting and ending points while simultaneously satisfying the specified position and velocity constraints at these points. Mathematically, the two PVT points provide four constraints—start position, start velocity, end position, and end velocity—which are exactly sufficient to solve for the four coefficients of the cubic polynomial:

P(t) = at³ + bt² + ct + d

Finally, the smooth motion trajectory is generated and executed. Using the solved P(t) function, the drive calculates the target position in real time at each control cycle throughout the motion from T0 to T0 + Ttotal, and commands the motor to follow accordingly. The velocity curve V(t) derived from the position function is parabolic, the acceleration curve A(t) varies linearly, and the jerk remains constant, ensuring that the entire motion is continuous, smooth, and free of shocks.

Comparison with another common approach: S-curve

In point-to-point motion control, S-curve acceleration and deceleration is also a widely adopted method for achieving smooth motion. In terms of the final motion outcome, both the S-curve and cubic interpolation under PVT mode can produce continuous and smooth velocity profiles, with similar effectiveness in suppressing shocks and vibrations. However, the two approaches differ significantly in their design philosophy and implementation methodology.

The S-curve mode is a parametric motion planning approach. Users typically only need to specify kinematic constraints such as total displacement, maximum velocity, maximum acceleration, and maximum jerk. The drive's internal motion planning algorithm then automatically generates a standard S-shaped velocity profile—either symmetrical or asymmetrical—based on these constraints, and computes the corresponding position commands by integrating the velocity profile. In this mode, users do not directly define specific velocity or position points along the time axis; the trajectory shape is primarily determined by the drive's internal algorithm.

PVT mode is a control approach that emphasizes explicit trajectory specification. Users define the skeleton of the motion trajectory by providing a set of precise "time–position–velocity" points. The drive then connects these discrete points into a continuous, smooth trajectory using mathematical interpolation methods, such as cubic polynomials. Because the trajectory is explicitly defined by the user, PVT mode offers significant flexibility, allowing for asymmetric motion, multi-segment velocity planning, and more complex trajectory shapes, rather than being limited to standard point-to-point S-curve acceleration and deceleration.

In summary, "point-to-point cubic interpolation in PVT mode" refers to the following: the user provides the drive with "time–position–velocity" information for the start and end points (and, if necessary, for intermediate points). Based on these constraints, the drive automatically computes an ideal motion trajectory using cubic polynomial interpolation, ensuring continuity in position and velocity as well as smooth acceleration. The drive then precisely controls the motor to follow this trajectory, achieving high-speed, smooth, and shock-free motion between the specified positions.

Thanks to its significant advantages in motion smoothness, trajectory controllability, and execution accuracy, point-to-point cubic interpolation in PVT mode has become a key motion control technique in high-end automation equipment. It is widely applied in scenarios demanding extremely high motion performance, such as semiconductor packaging systems, precision machine tools, and industrial robots.