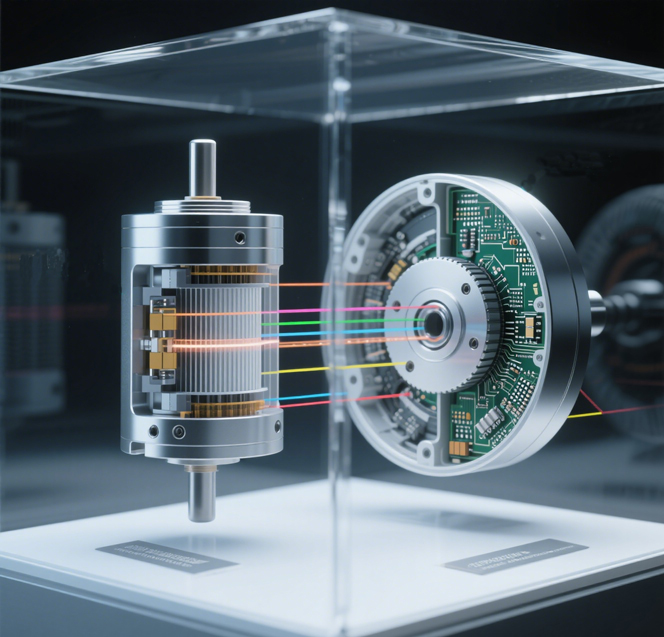

Servo Motor Encoder

In the servo system, the servo motor encoder is the core feedback component. The encoder is used to monitor the motor's speed, position, and direction in real-time, feeding this information back to the controller to form a closed-loop system, ensuring precise execution of the motor's instructions. The main functions of the servo encoder include: Position feedback, it accurately measures the absolute or relative position of the motor rotor; Speed feedback, by counting the number of pulses per unit of time, the motor speed is determined; Direction detection, using two pulse signals with a 90° phase difference (A/B phase), the motor's direction is precisely detected. Closed-loop control foundation, it provides real-time data to the controller to help correct any errors generated during motor movement.

The performance of the servo motor encoder directly affects the system's accuracy and stability. When selecting a servo motor, it is important to consider the application scenario, environmental conditions, and cost requirements.

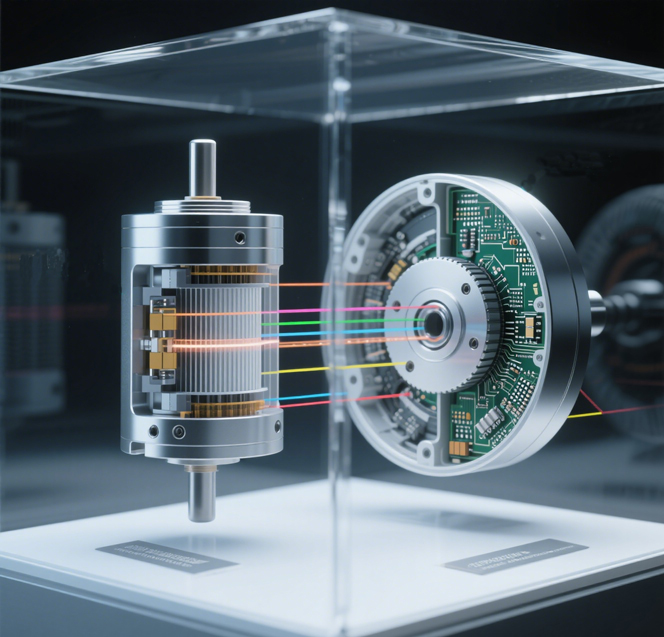

There are various types of servo motor encoders, mainly in the following categories:

Incremental Encoder: The incremental encoder works by outputting a pulse signal proportional to the rotation angle, typically including A, B, and Z phases. The A and B phases are two square wave pulses with a 90° phase difference, which are used to calculate the position and direction; the Z phase serves as a zero position signal, outputting one pulse per full rotation, mainly used to calibrate the origin. The incremental encoder is known for its relatively low cost and simple structure. However, if the power is lost, the position information is lost as well, requiring a return to zero operation after each power-on. It is commonly used in general servo systems and speed control applications. Absolute Encoder: The absolute encoder works on the principle that each position corresponds to a unique binary code, allowing it to directly output the absolute position value. The single-turn absolute encoder records the absolute position within one full rotation (360°); while the multi-turn absolute encoder additionally tracks the number of complete rotations of the shaft, typically using gears or electronic counting. A key feature of the absolute encoder is that the position information is retained even after a power failure, eliminating the need for calibration. It offers high resolution and strong resistance to interference. It is widely used in high-precision positioning applications, such as industrial robots, CNC machine, and more. Hybrid encoder: It cleverly combines the advantages of incremental and absolute encoders, outputting incremental pulses while providing absolute position information.The performance of the servo motor encoder directly affects the system's accuracy and stability. When selecting a servo motor, it is important to consider the application scenario, environmental conditions, and cost requirements.