The Challenges of Making Small LED Drivers

Over the past 10 years, LED chip technology has evolved rapidly. There are some large semiconductor manufacturers who are constantly involved in the development of LED chips with high luminous efficiency, and they are now capable of producing small-volume and high-efficiency LED chips (lumens per watt). The high performance of these LEDs led to the development of luminaire designs with sleek, slender, and other aesthetically pleasing case shapes. The development of high-power density power supplies has been a slow process for LED driver manufacturers. In other words, high-power density power supplies have a small volume and a high power density (watts per cubic). As the large volume of power supply limits the creative potential of luminaire designers, the need to reduce LED drivers is a priority.

Reducing the size of the LED driver will reduce the size of the LED-driven heat sink. As a result, the temperature will rise, reducing the drive's lifespan. Despite the challenges associated with the development of small-volume power supplies, MOONS' has been operating in the field of LED drivers for more than a decade.

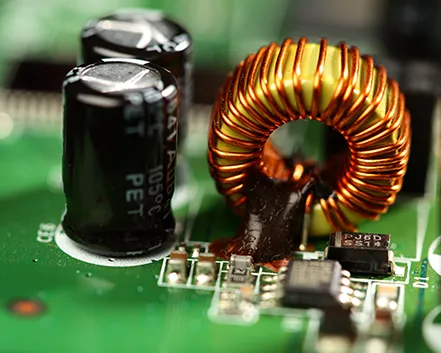

Utilizing integrated electronic components

Integration is a key factor in size reduction. MOONS' LED drivers utilize the most integrated ICs from very reputable IC manufacturers, although at a higher component cost. A power designer is primarily concerned with circuit design and topology optimization. Quasi-resonance circuits have the advantage of saving energy and reducing thermal losses. Throughout the years, MOONS' electrical engineers have mastered the art of balancing driver performance, reliability, and cost.

Minimizing mechanical size

A driver's mechanical size can be minimized by carefully considering every component. We optimize the converted magnetics transformer from the transformer manufacturer according to its special shape since it is a giant compared to other electronics. A double-layer PCB or even a four-layer PCB is also a key factor in shrinking the mechanical size. To achieve high power density, it is vital to minimize noise paths and optimize the flow of energy through the converter.

Managing the performance and energy efficiency

All methods must be balanced in terms of performance and energy efficiency in the final analysis. If energy efficiency is not achieved, MOONS' LED drivers cannot achieve significant size reductions and maintain high reliability and long life. To keep temperature-sensitive components as cool as possible, some thermal design techniques are used. The MOONS' drivers add a heat sink to conduct heat more evenly to the driver's case shell which is wavy design, which allows for stable operation in free air convection.

Here are MOONS' compact and powerful LED drivers.