- Home

- Technical College

- SERVO MOTORS

- Application Cases | The performance engine of laser cutting equipment

Application Cases | The performance engine of laser cutting equipment

In recent years, the global laser industry has experienced rapid growth. Laser technology has been widely integrated into various industries, including photovoltaic, lithium batteries, and healthcare, becoming a key driver of progress across these sectors. In manufacturing, laser cutting machines, which combine multiple advanced technologies into high-tech equipment, play a key role in the production process. With their precision, efficiency, and speed in material cutting, providing significant support for the growth of the manufacturing industry.  Equipment features: Primarily designed for medium and thin plates, such as carbon steel and stainless steel, not limited to cutting patterns, automatic nesting to save materials, smooth cut edges, low cost, high speed, and high precision cutting.

Equipment features: Primarily designed for medium and thin plates, such as carbon steel and stainless steel, not limited to cutting patterns, automatic nesting to save materials, smooth cut edges, low cost, high speed, and high precision cutting.  In the field of laser processing, there are high demands for the accuracy, speed, and automation of laser cutting machines. With its expertise, MOONS' provides a comprehensive and practical motion control solution for this industry, including servo drives and motors, which significantly enhance the performance of laser cutting machines.

In the field of laser processing, there are high demands for the accuracy, speed, and automation of laser cutting machines. With its expertise, MOONS' provides a comprehensive and practical motion control solution for this industry, including servo drives and motors, which significantly enhance the performance of laser cutting machines.  System topology diagram This solution utilizes the MOONS' M5 series AC servo system, which can accurately control the motion trajectory of the cutting head during the cutting process. It ensures high-precision cutting, whether for high-speed cutting or processing complex patterns or small parts. This effectively enhances both cutting efficiency and quality, meeting the practical demands of industrial production. As industrial automation advances rapidly and the demand for precision and efficiency in manufacturing continue to rise, high-performance servo systems have become a key force in driving industrial upgrades and supporting precision manufacturing. MOONS' M5 AC servo system addresses the diverse needs of industrial environments by integrating control methods such as pulse, analog, and Q programming, allowing for flexible responses to instructions. It is fully compatible with common industrial fieldbuses such as EtherCAT, CANopen, Modbus, EtherNet/IP, and Profinet, offering customers motion control solutions that are better suited to their equipment. This system is widely used in battery processing equipment, electronic and semiconductor processing, solar processing, medical devices, robots, and non-standard equipment, etc. helping to establish a flexible and efficient production system on site.

System topology diagram This solution utilizes the MOONS' M5 series AC servo system, which can accurately control the motion trajectory of the cutting head during the cutting process. It ensures high-precision cutting, whether for high-speed cutting or processing complex patterns or small parts. This effectively enhances both cutting efficiency and quality, meeting the practical demands of industrial production. As industrial automation advances rapidly and the demand for precision and efficiency in manufacturing continue to rise, high-performance servo systems have become a key force in driving industrial upgrades and supporting precision manufacturing. MOONS' M5 AC servo system addresses the diverse needs of industrial environments by integrating control methods such as pulse, analog, and Q programming, allowing for flexible responses to instructions. It is fully compatible with common industrial fieldbuses such as EtherCAT, CANopen, Modbus, EtherNet/IP, and Profinet, offering customers motion control solutions that are better suited to their equipment. This system is widely used in battery processing equipment, electronic and semiconductor processing, solar processing, medical devices, robots, and non-standard equipment, etc. helping to establish a flexible and efficient production system on site.  Motor structure: adopts a new structure and magnetic circuit design, resulting in a more compact size and higher efficiency. Protection level: After installing the oil seal, the motor meets the IP67 protection level, offering enhanced dustproof and waterproof capabilities for greater reliability. High speed and high torque: With a speed of up to 6000rpm and an overload torque 3.5 times higher, which helps to significantly increase the equipment capacity. Multiple encoder options: Servo motors can be equipped with 26-bit, 21-bit battery-equipped, and 17-bit battery-free multi-turn absolute encoders. Selecting the appropriate encoder motor can enhance equipment performance and optimize system costs.

Motor structure: adopts a new structure and magnetic circuit design, resulting in a more compact size and higher efficiency. Protection level: After installing the oil seal, the motor meets the IP67 protection level, offering enhanced dustproof and waterproof capabilities for greater reliability. High speed and high torque: With a speed of up to 6000rpm and an overload torque 3.5 times higher, which helps to significantly increase the equipment capacity. Multiple encoder options: Servo motors can be equipped with 26-bit, 21-bit battery-equipped, and 17-bit battery-free multi-turn absolute encoders. Selecting the appropriate encoder motor can enhance equipment performance and optimize system costs.

1. Device information description

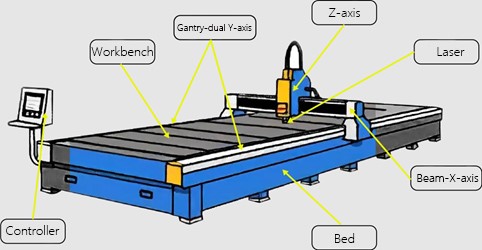

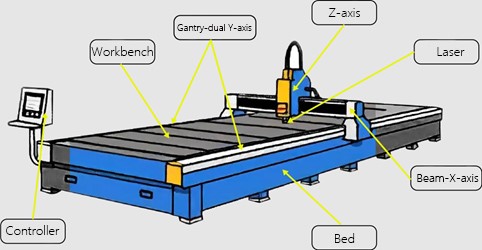

The laser cutting machine focuses the laser emitted from the laser source into a high-power density laser beam through the optical system. This laser beam is directed onto the surface of the workpiece, raising it to its melting point or boiling point. At the same time, high-pressure gas coaxial with the beam blows away the molten or vaporized metal. As the relative position of the beam and the workpiece changes, a slit is formed in the material, achieving the cutting process. Equipment features: Primarily designed for medium and thin plates, such as carbon steel and stainless steel, not limited to cutting patterns, automatic nesting to save materials, smooth cut edges, low cost, high speed, and high precision cutting.

Equipment features: Primarily designed for medium and thin plates, such as carbon steel and stainless steel, not limited to cutting patterns, automatic nesting to save materials, smooth cut edges, low cost, high speed, and high precision cutting. 2. Equipment composition

In the field of laser processing, there are high demands for the accuracy, speed, and automation of laser cutting machines. With its expertise, MOONS' provides a comprehensive and practical motion control solution for this industry, including servo drives and motors, which significantly enhance the performance of laser cutting machines.

In the field of laser processing, there are high demands for the accuracy, speed, and automation of laser cutting machines. With its expertise, MOONS' provides a comprehensive and practical motion control solution for this industry, including servo drives and motors, which significantly enhance the performance of laser cutting machines. Laser sheet metal cutting machine MOONS' solution detailed explanation

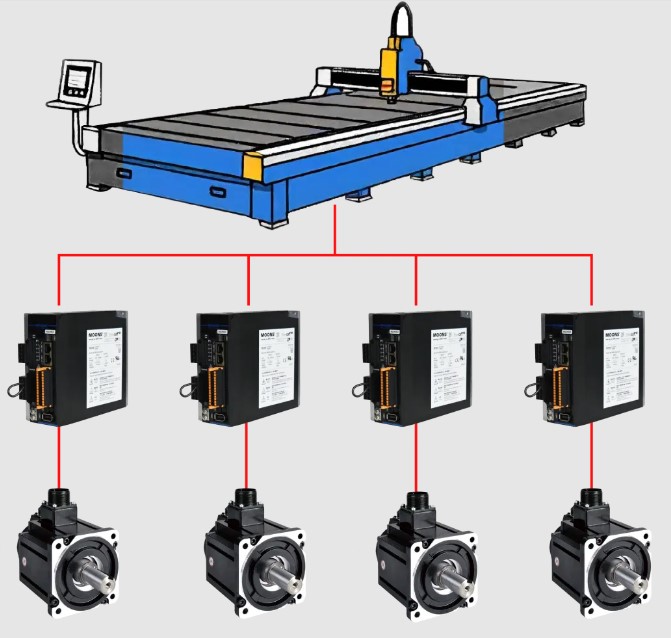

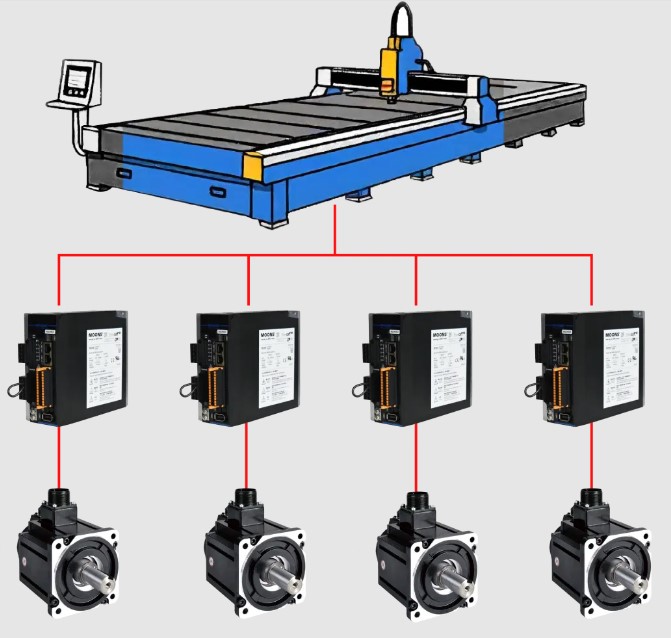

Taking the laser sheet metal cutting machine as an example, the solution utilizes a dedicated bus CNC system and achieves high-speed, stable communication between system components through the EtherCAT bus, providing a solid foundation for the precise operation of the equipment. System topology diagram This solution utilizes the MOONS' M5 series AC servo system, which can accurately control the motion trajectory of the cutting head during the cutting process. It ensures high-precision cutting, whether for high-speed cutting or processing complex patterns or small parts. This effectively enhances both cutting efficiency and quality, meeting the practical demands of industrial production. As industrial automation advances rapidly and the demand for precision and efficiency in manufacturing continue to rise, high-performance servo systems have become a key force in driving industrial upgrades and supporting precision manufacturing. MOONS' M5 AC servo system addresses the diverse needs of industrial environments by integrating control methods such as pulse, analog, and Q programming, allowing for flexible responses to instructions. It is fully compatible with common industrial fieldbuses such as EtherCAT, CANopen, Modbus, EtherNet/IP, and Profinet, offering customers motion control solutions that are better suited to their equipment. This system is widely used in battery processing equipment, electronic and semiconductor processing, solar processing, medical devices, robots, and non-standard equipment, etc. helping to establish a flexible and efficient production system on site.

System topology diagram This solution utilizes the MOONS' M5 series AC servo system, which can accurately control the motion trajectory of the cutting head during the cutting process. It ensures high-precision cutting, whether for high-speed cutting or processing complex patterns or small parts. This effectively enhances both cutting efficiency and quality, meeting the practical demands of industrial production. As industrial automation advances rapidly and the demand for precision and efficiency in manufacturing continue to rise, high-performance servo systems have become a key force in driving industrial upgrades and supporting precision manufacturing. MOONS' M5 AC servo system addresses the diverse needs of industrial environments by integrating control methods such as pulse, analog, and Q programming, allowing for flexible responses to instructions. It is fully compatible with common industrial fieldbuses such as EtherCAT, CANopen, Modbus, EtherNet/IP, and Profinet, offering customers motion control solutions that are better suited to their equipment. This system is widely used in battery processing equipment, electronic and semiconductor processing, solar processing, medical devices, robots, and non-standard equipment, etc. helping to establish a flexible and efficient production system on site. M5 series AC servo system features

1. 26-bit high-resolution multi-turn absolute encoder. 2. Velocity loop bandwidth of up to 3.5 kHz. 3. Super tracking control algorithm. 4. External disturbance Compensation. 5. Dynamic braking function, 6. Full closed-loop functionality, 7. UL, CE, STO (SIL3 PLe) certificationM5 Series Servo Motor Features

Motor structure: adopts a new structure and magnetic circuit design, resulting in a more compact size and higher efficiency. Protection level: After installing the oil seal, the motor meets the IP67 protection level, offering enhanced dustproof and waterproof capabilities for greater reliability. High speed and high torque: With a speed of up to 6000rpm and an overload torque 3.5 times higher, which helps to significantly increase the equipment capacity. Multiple encoder options: Servo motors can be equipped with 26-bit, 21-bit battery-equipped, and 17-bit battery-free multi-turn absolute encoders. Selecting the appropriate encoder motor can enhance equipment performance and optimize system costs.

Motor structure: adopts a new structure and magnetic circuit design, resulting in a more compact size and higher efficiency. Protection level: After installing the oil seal, the motor meets the IP67 protection level, offering enhanced dustproof and waterproof capabilities for greater reliability. High speed and high torque: With a speed of up to 6000rpm and an overload torque 3.5 times higher, which helps to significantly increase the equipment capacity. Multiple encoder options: Servo motors can be equipped with 26-bit, 21-bit battery-equipped, and 17-bit battery-free multi-turn absolute encoders. Selecting the appropriate encoder motor can enhance equipment performance and optimize system costs.