E5718 Series Hercules High Torque Stepper Motor

Frame Size: NEMA 23 | Step Angle: 1.8° • Up To 600 oz-in (4.24 Nm) of Holding Torque• 40% more torque than standard NEMA 23 stepper motors

• High Torque Per Size Ratio

• Custom Windings Available (No additional cost) Contact Us for More

Lin Engineering is pleased to release the new Xtreme Torque E5718 Stepper Motor with Enhanced Technology. The Xtreme Torque Stepper Motor with Enhanced Technology has been designed to reduce stalling, skipped steps, and provide efficient torque to keep your application continuously running smoothly. This new enhanced design allows you to stay within the same frame size and still take advantage of the increased torque and added benefits normally only available in larger frame sizes.

How Did We Do It?

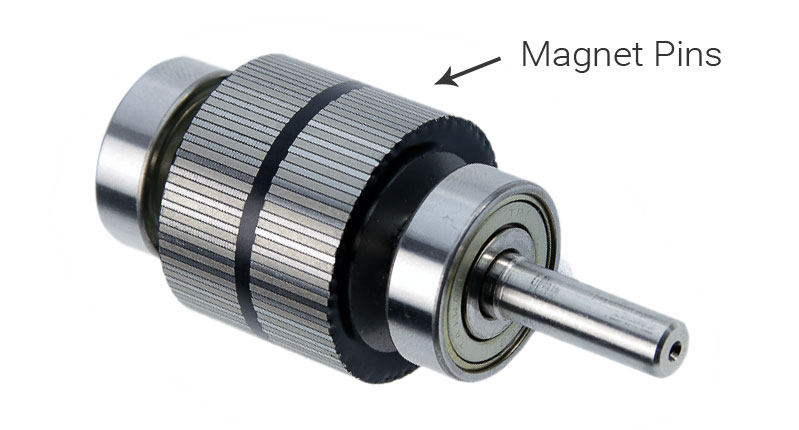

Inherently, every stepper has flux leakage which equates to torque loss. By inserting magnetic pins within the rotor, we were able to mitigate flux leakage, resulting in improved torque by up to 40%.

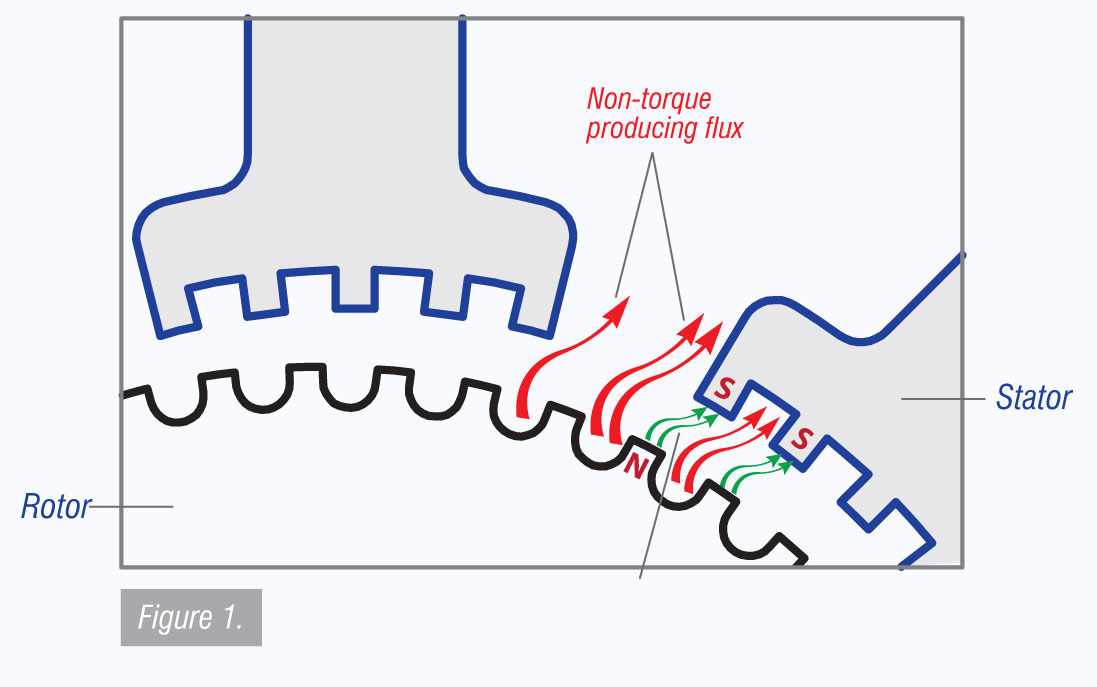

Standard Stepper Motors

All standard stepper motors experience some non-torque producing flux, or flux leakage.

Figure 1. Typical Stepper Motor Flux Path

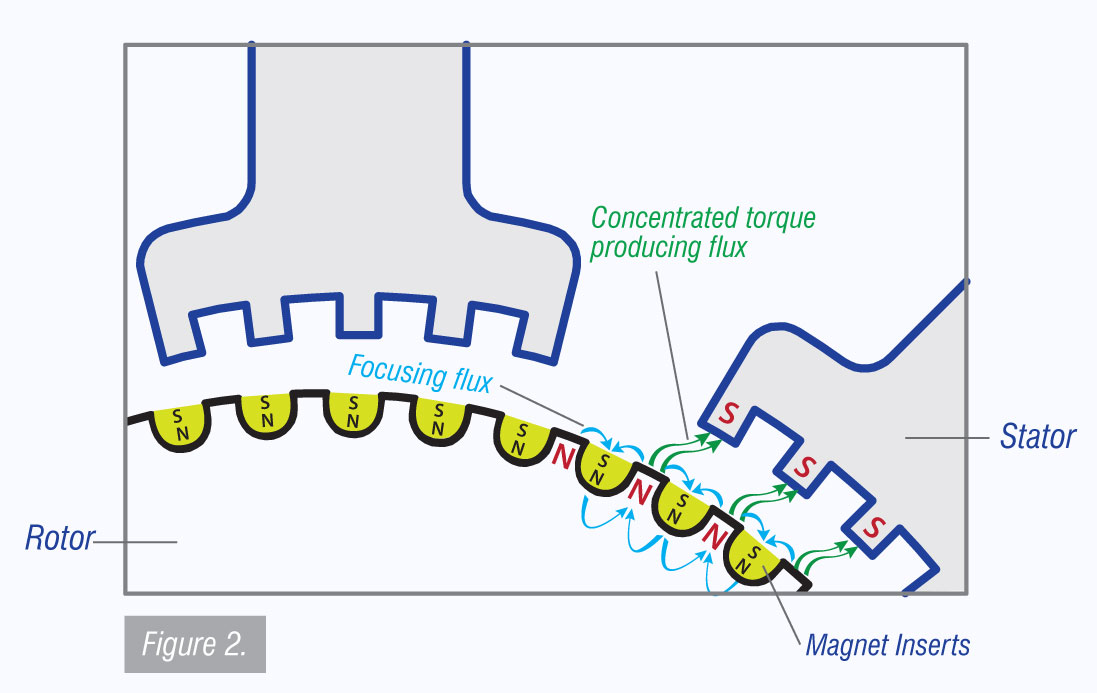

Hercules Stepper Motors

Magnet pins are located between rotor teeth. Full circumferential coverage over rotor increases focusing flux and overall torque performance.

Figure 2. Lin Engineering Hercules Motor Flux Path

More Holding Torque

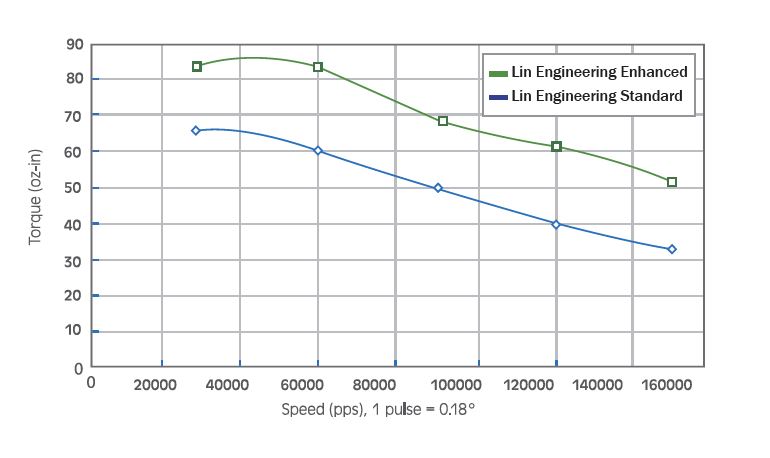

Hercules steppers provide up to 40% more torque throughout the entire speed range than standard motor of the same size.

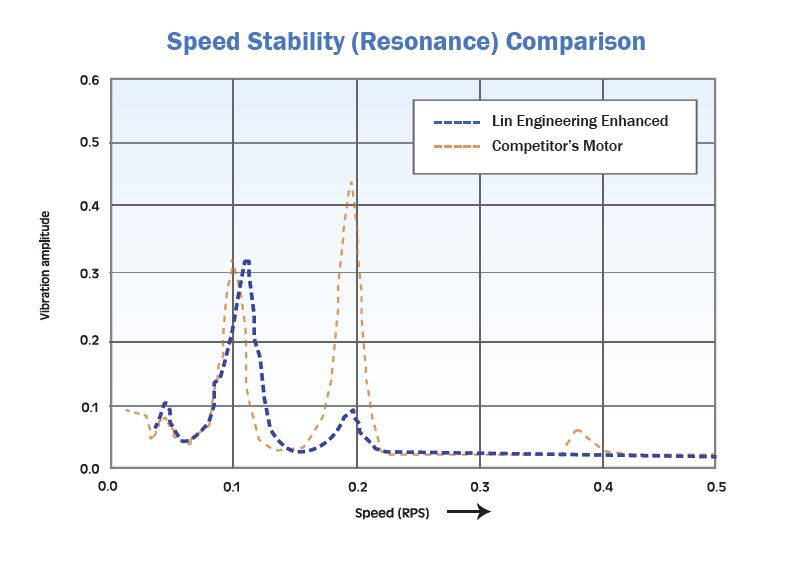

Less Resonance

Hercules steppers generate less resonant frequency due to the oscillation. Making the motor smoother, quieter, and precise.