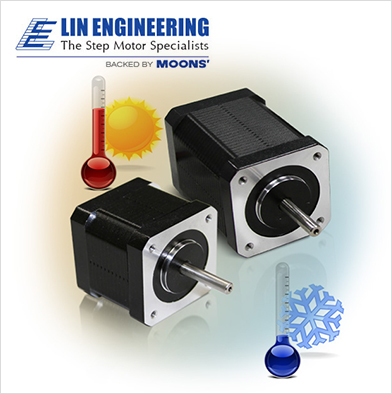

Hot/Cold Specialty Motors

Type I • Type I operates in ambient temperatures from -40 degrees C (-40 degrees F) to80 degrees C (176 degrees F) and up to 110 degrees C (230 degrees F) for the case temperature. Type II • Type II operates in ambient temperatures from -40 degrees C to 110 degrees C

(230 degrees F) with up to 140 degrees C (284 degrees F) for the case temperature. Contact Us for More

Lin Engineering standard motors are rated to operate in ambient temperatures between 50 degrees C and -20 degrees C. While this satisfies the majority of uses, there are certain applications that require the motor to operate at higher or lower temperature ranges than what standard motors allow for. Unfortunately, operating standard motors anywhere outside these temperature ranges will result in poor performance. Like any specific application concerns, motors that must work under extreme conditions of hot and cold require critical design features to accommodate their use. Whether your application is situated in the heat of a desert or the freezing temperatures of the arctic, Lin Engineering has the expertise to provide the right motor for you. The company has designed two types of specialty hot/cold motors meant to operate specifically in extreme temperature ranges-Type I and Type II.

Designing specialty motors that handle wide variations in temperature often includes three component adjustments

|  |  |

the type of magnet used in the rotor stack | the magnet wire used to wind the motor | the type of bearings used |

Motor Options

| Motor Frame | Torque Range |

| NEMA 8 (20mm) | up to 4 oz-in (0.03Nm) |

| NEMA 11 (28mm) | up to 16 oz-in (0.12Nm) |

| NEMA 17 (42mm) | up to 115 oz-in (0.81Nm) |

| NEMA 23 (57mm) | up to 305 oz-in (2.16Nm) |

| NEMA 34 (80mm) | up to 1,288 oz-in (9.09Nm) |

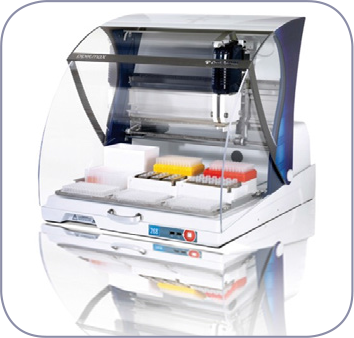

Application Examples

| Refrigerated Environments Medical and Laboratory equipment such as liquid handlers or devices exposed to moisture or particles. |  | Heated Environment Perfect for use in devices operating in heated environments or exposed to heat for extended periods of time. |