New Generation NEMA 8 Stepper Motor

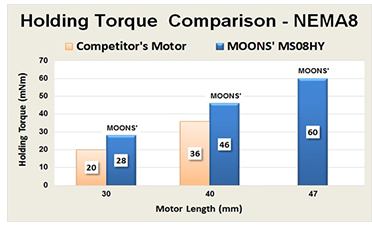

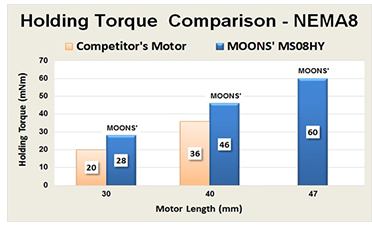

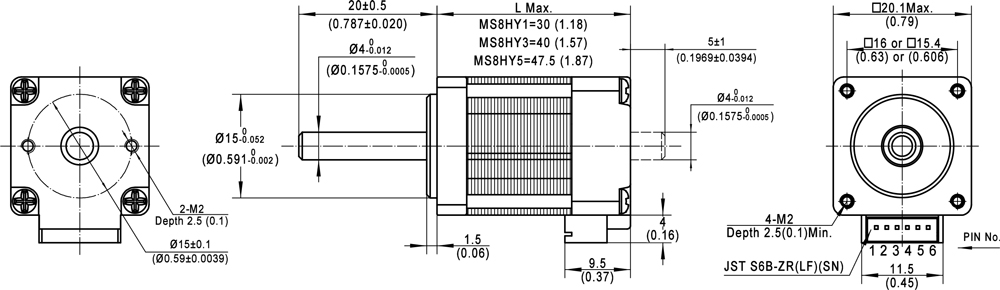

Nema 8 (口20mmX20mm), 2-phase, 1.8° • Innovation round flange, motor body diameter is only Φ22mm• 27%-40% more holding torque, up to 8.5 oz-in (60 mNm)

• 18.5% lower volume and approximately 10% less weight than conventional motors

• Innovation round flange provides flexible and customized mounting solutions

• Variety of mounting connection modes: facing forward, out the side of the motor,or out the rear of the motor for flexibility and space savings

• Customizations available include motor windings, various shafts, motor leads and connectors and encoder & gearhead options For details, please see the product page

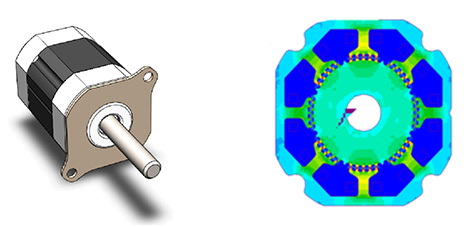

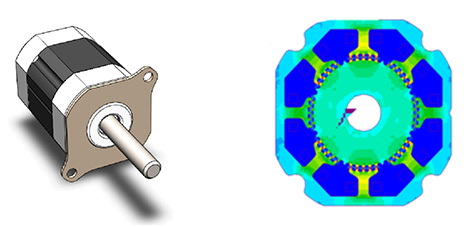

MOONS' MS08HY series is a compact size HB step motor specifically designed to be applied in small precision instruments. Continuous investment in product research, and advanced electromagnetic simulation has allowed MOONS' to optimize its performance. As a result the new MS08HY series motor is a compact, high efficient, high performance step motor. This design also allows for more mounting and connection options to best fit any application.

High Torque

Optimized magnetic circuit design gives higher efficiency and higher torque.

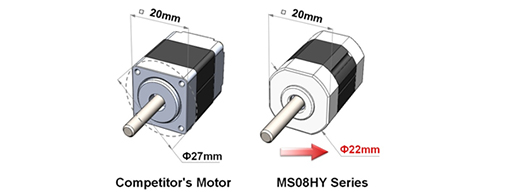

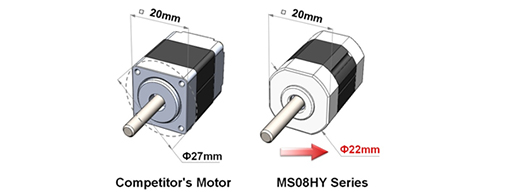

Compact Structure – Save Space & Weight

MS08HY series has a smaller body diameter compared with conventional designs. The diameter is reduced from Φ27mm to Φ22mm. Its volume is 18.5% lower and its weight is approximately 10% less than conventional motors. This helps to achieve the customer's requirement for smaller and lighter solutions to better improve their products.

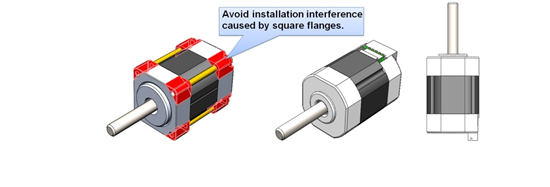

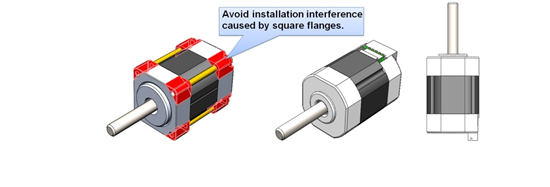

Flexible Machine Designs

MS08HY series has two flange options: square flange and round flange. The square flange option has the same mounting as conventional Nema 8 designs. The round flange is a MOONS' innovation to save even more space, further reduce weight, and allows these motors to take the place of other round motor technologies. Combined with multiple wire outlet options, it lets customers easily design very compact equipment and meet the requirement of high-tech applications such as: portable medical equipment, surveillance cameras, electronic microscopes, actuators, etc.

Variety of Mounting and Connection Modes

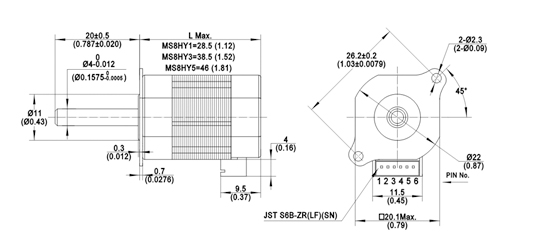

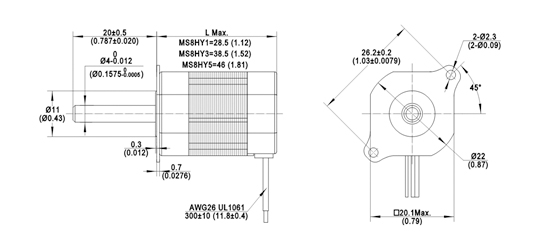

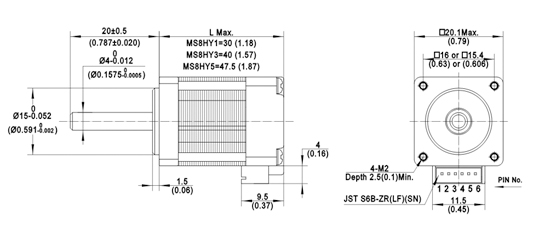

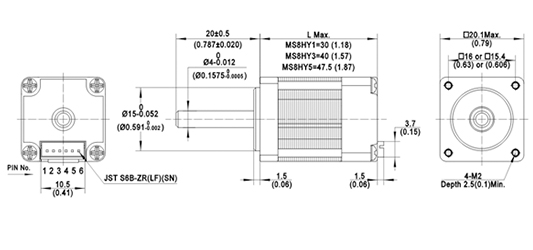

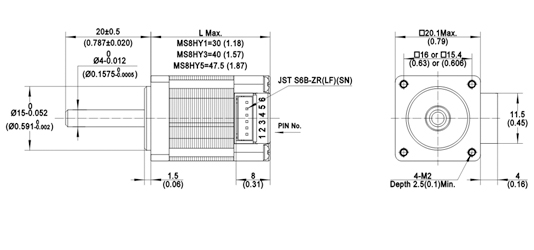

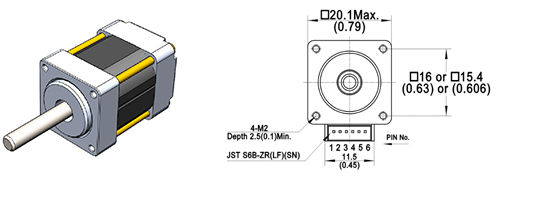

· Square Flange Mounting

The square flange is a standard HB Step design. MS08HY series square flange design provides the option of two square mounting dimensions: 15.4mm or 16mm, covering all requirements in the market.

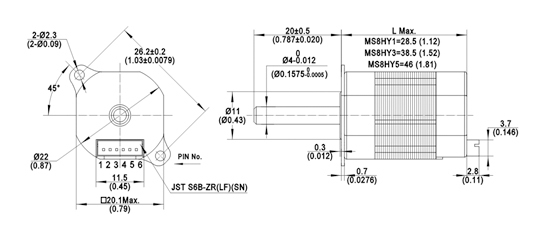

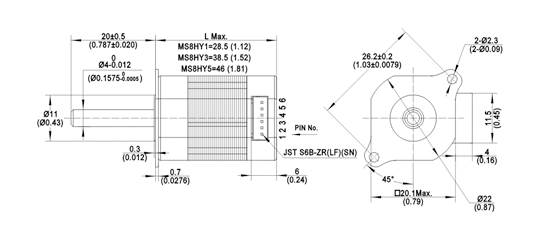

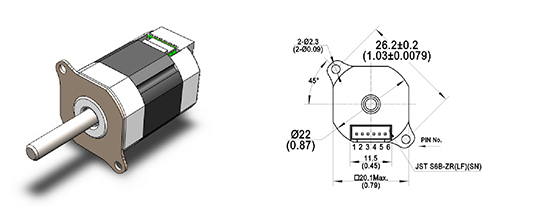

· Round Motor Flange Mounting

MOONS' has developed an innovative round flange design which is matches perfectly to the new stator lamination. This standard mounting plate allows the mounting screws to be assembled from the same side as the motor, which can make it easier to install as well as makes the entire body very compact. The use of a separate mounting plate also makes it easy for MOONS' to provide customized mounting solutions to fit the specific application.

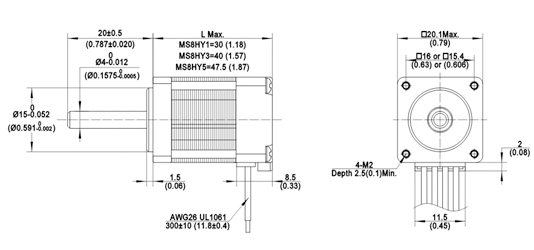

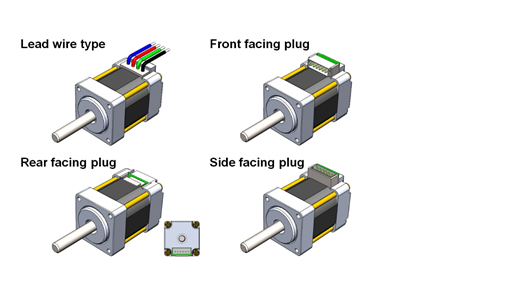

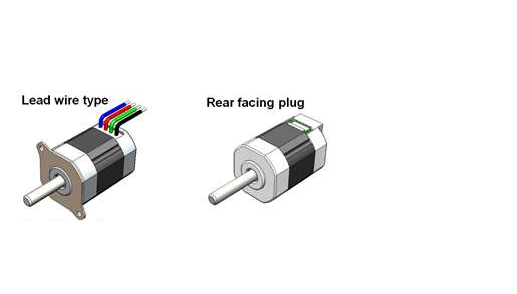

· Lead Wire and Plug Connections

Lead wires provide a permanent connection to the motor. They can be customized in any lead length with connectors provided on the end of the leads as an option. This allows the motor to be connected directly to the motor drive. Plug connections now have the option of facing forward, out the side of the motor, or out the rear of the motor. The rear facing connector is confined entirely within the motor body shape. This allows for further flexibility and space savings.Mounting and Connection Options

Customers now have the flexibility to design small, compact equipment that is easy to assemble.· Square Flange

· Round Flange

Customized Motor & Recommended Options

These motors are routinely used in low to high volume production applications. Our Standard motors offer standard customizations, and come with extended customer and product support. Customizations available include motor windings for optimal performance under your specific operating conditions, various shaft customizations; and customized motor leads and connectors.

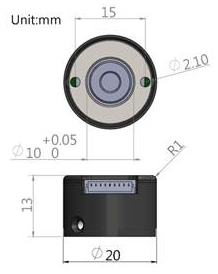

· High Accuracy in Closed Loop Control(Encoder Required)

MS08HY series stepper motor is small in size, but can still be assembled with photoelectric rotary encoders. The customer can make a closed loop control system for the motor, using a simple system realizing higher reliability and efficiency vs. an open loop system. Also, this closed loop system has further advantages of low vibration, low heating and stable stopping. · Mounting Dimensions of Encoder · Recommended Encoders

· Recommended Encoders Product: photoelectric rotary encoder

Type: HS20A

resolution: 1000 P/R

signal: A, B, Z

voltage: 4.5 ~ 5.5 VDC

input current: 60 mA (Max)

response frequency: 220 kHz

operating temperature: -20 ~ +85℃

Type: HS20A

resolution: 1000 P/R

signal: A, B, Z

voltage: 4.5 ~ 5.5 VDC

input current: 60 mA (Max)

response frequency: 220 kHz

operating temperature: -20 ~ +85℃

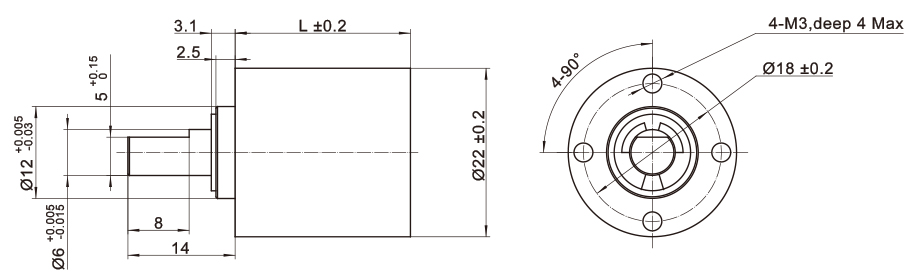

· MS08HY Series Stepper Motor + Planetary Gearhead

Compact and lightweight assembly increases the output torque with small gap, high efficiency and low noise. · Recommended Gearhead| Gearhead Data | |||||

| Reduction Ratio | 4:1 | 16:1 | 64:1 | 256:1 | |

| 5:1 | 19:1 | 76:1 | 304:1 | ||

| 22:1 | 90:1 | 361:1 | |||

| 107:1 | 428:1 | ||||

| 509:1 | |||||

| Number of stages | 1 | 2 | 3 | 4 | |

| Max. continuous torque | Nm | 0.20 | 0.40 | 0.60 | 0.80 |

| Max. intermittent torque | Nm | 0.30 | 0.60 | 0.90 | 1.20 |

| Weight | g | 34.3 | 34.6 | 54.4 | 64.0 |

| Max. efficiency | % | 81 | 66 | 53 | 43 |

| Gearhead length L | mm | 17.7 | 22.9 | 28.1 | 33.3 |

| Specification | ||

| Planetary gearhead | Straight teeth | |

| Output shaft | Stainless steel, hardened | |

| Bearing at output | Sleeve bearing | |

| Radial play | mm | ≤ 0.1 |

| Axial play | mm | ≤ 0.35 |

| Max. radial load | N | 8 |

| Max. axial load | N | 15(5mm from flange) |

| Max. force for press fits | N | 100 |

| Recommend input speed | rpm | ≤10000 |

| Direction of rotation (drive to output) | = | |

| Ambient temperature | ℃ | -10~+60 |

Specification

| Length | Model Number | Connect | Rated Current | Holding Torque | Winding | Rotor Inertia | Motor Weight | |||

| Single Shaft | P=Plug L=Leads | Amps (mounted) | Nm Typ. | Oz-in Typ. | Ohms @20℃ | g.cm² | Oz-in² | Kg | Lbs | |

| 30mm | MS08HY1 | P | 0.5 | 0.028 | 4 | 8.2 | 2.7 | 0.015 | 0.045 | 0.1 |

| 40mm | MS08HY3 | P | 0.5 | 0.046 | 6.5 | 14.1 | 3.6 | 0.02 | 0.062 | 0.14 |

| 47.5mm | MS08HY5 | P | 0.5 | 0.06 | 8.5 | 17.4 | 4.2 | 0.023 | 0.075 | 0.17 |

| Phases | Steps/ Revolution | Step Accuracy | IP Class | Approvals | Operating Temp | Insulation Class | Insulation Resistance | Shaft Load (20,000 Hours at 1000 RPM) | |

| Axial | Radial | ||||||||

| 2 | 200 | ±5% | 40 | RoHS | -20°C to +50°C | B, 130°C | 100 MegOhms | 6 N (1.3 Lbs.) Push 25 N (5.6 Lbs.) Pull | 18 N (4 Lbs.) At end of shaft |

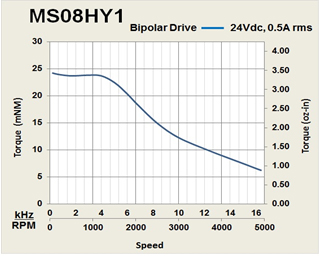

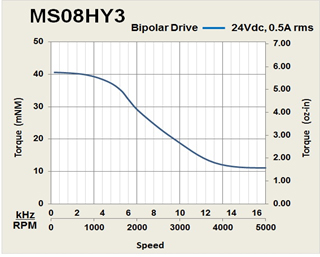

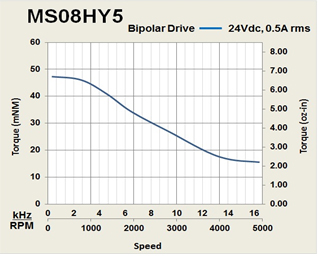

Torque Curves

|  |  |