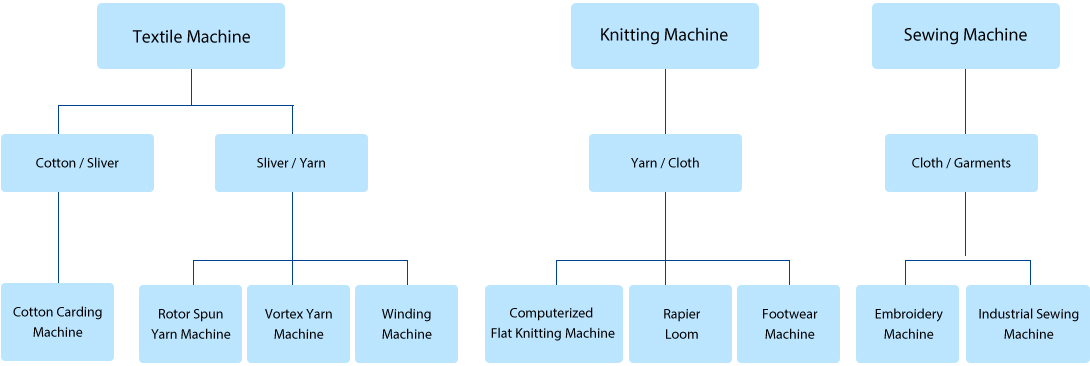

Textile Manufacturing

Textile machines are used for processing natural fiber and chemical fiber into textiles. Due to the adjustment of textile product structure and market demand, modern textile machines tend to standardize, serialize, and universalize the procedure which should be high speed, high efficiency, and maintenance-free as well as low consumption, low noise, and low pollution, to achieve manufacturability, continuity and completeness.

Textile machines are used for processing natural fiber and chemical fiber into textiles. Due to the adjustment of textile product structure and market demand, modern textile machines tend to standardize, serialize, and universalize the procedure which should be high speed, high efficiency, and maintenance-free as well as low consumption, low noise, and low pollution, to achieve manufacturability, continuity and completeness.Worldwide, driven by the market demand, the industrial competition has shifted from textile manufacturing powers like German, Italy, and Switzerland to the Asian market, among which China has grown into the most leading textile manufacturing nation in the world.

Meanwhile, various machines are required due to different procedures. There are three types of machine as follows in terms of manufacturing function.

Textile Machine (Winding Machine)

Knitting Machine (Rapier Loom)

Sewing Machine (Bar Tacking Machine)

• Special Design of Bore and Shaft

Relative movement between bearing bore and shaft during operation will cause friction and heat, affecting service life of bearing.

• Due to reciprocating and high speed operation of bearing in small angle under radial and axial load, ball will constantly hit the bearing grooves, which will cause abrasion and noise and shorten its service life.

• Low Power Consumption; Low Temperature Rise; Long Life

Continuous operation and radial pressure will shorten motors’ longevity.

2、Ultra high torque of PL Series(with high pressure driving control system): High efficiency; Low power consumption; Low temperature rise

3、Closed loop design(with dust proof and long-life bearing): High reliability; Long service life; Low temperature rise; Higher response frequency; Higher speed; Reasonable system cost

4、Linear transmission and application:Belt drive; Lead screw drive; Linear motor solution