What is a Frameless Torque Motor?

Frameless torque motors are high-torque, direct-drive motors designed without a housing or shaft, offering exceptional flexibility for customized applications. Their specialized structural allows for direct integration into the mechanical system of equipment, enabling seamless and compact assembly. Owing to their frameless design, these motors are especially well-suited for applications requiring compactness, lightweight construction, and high power density. Typical use cases include industrial robotics, aerospace systems, medical equipment, and industrial automation.  In this article, we will explore key aspect of frameless torque motors, including their structure, advantages, applications, and how to evaluate whether they are the right solution for a specific engineering project.

In this article, we will explore key aspect of frameless torque motors, including their structure, advantages, applications, and how to evaluate whether they are the right solution for a specific engineering project.

Robotics: With their high torque output, smooth motion and precise control, frameless torque motors serve as the core driving force behind industrial and service robots performing complex tasks. Aerospace: The lightweight and high power density characteristics make it suitable for aviation-grade application such as drone rotor drives and flight control systems. Medical Devices: Frameless motors are used in medical equipment to power robotic surgical systems and other precision instruments that demand compactness and accuracy. Industrial Automation: Frameless torque motors enable precise motion control in automated machinery and are especially well-suited for high-torque, low-speed applications (such as machine tool feed systems). Electric Vehicles (EVs): EV manufacturers utilize frameless torque motors to ensure an optimal balance between vehicle acceleration performance and energy utilization through high efficiency and high torque characteristics.

Robotics: With their high torque output, smooth motion and precise control, frameless torque motors serve as the core driving force behind industrial and service robots performing complex tasks. Aerospace: The lightweight and high power density characteristics make it suitable for aviation-grade application such as drone rotor drives and flight control systems. Medical Devices: Frameless motors are used in medical equipment to power robotic surgical systems and other precision instruments that demand compactness and accuracy. Industrial Automation: Frameless torque motors enable precise motion control in automated machinery and are especially well-suited for high-torque, low-speed applications (such as machine tool feed systems). Electric Vehicles (EVs): EV manufacturers utilize frameless torque motors to ensure an optimal balance between vehicle acceleration performance and energy utilization through high efficiency and high torque characteristics.

In this article, we will explore key aspect of frameless torque motors, including their structure, advantages, applications, and how to evaluate whether they are the right solution for a specific engineering project.

In this article, we will explore key aspect of frameless torque motors, including their structure, advantages, applications, and how to evaluate whether they are the right solution for a specific engineering project. Structure of Frameless Torque Motor

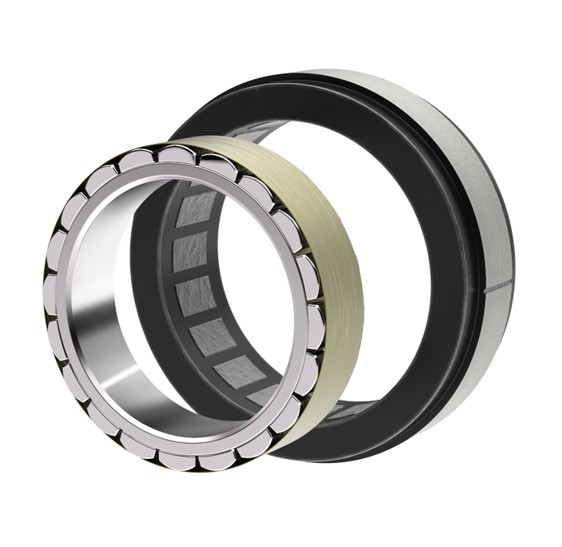

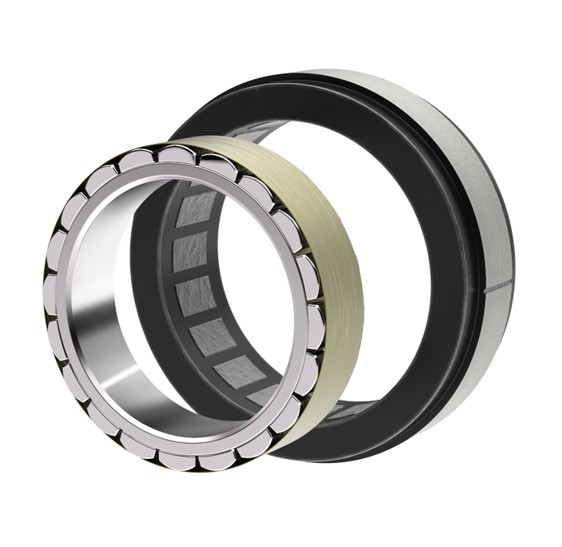

A frameless torque motor features a structure without a traditional housing or shaft and consists of two core components: the rotor, which generates torque to produce rotational motion, and the stator drives the rotor through electromagnetic field generated by its windings. Unlike conventional motors, frameless torque motors eliminate the needs for a housing and mounting frame. The term "Frameless" refers to the ability of the rotor and stator to be directly integrated into the transmission mechanism of the target system. This form of integration streamlines the mechanical structure, enabling more optimized motor sizing and weight configuration based on specific application requirements.

Working Principle of Frameless Torque Motor

Frameless torque motors operate on the same principle as traditional electric motors: when current flows through the stator windings, it generates an electromagnetic field that interacts with the rotor's permanent magnets to produce rotational torque and rotate the rotor. The low-speed, high-torque characteristics make them well-suited for applications requiring precise low-speed control. Compared to traditional motors that rely on gear or belt transmissions, the direct-drive design of frameless torque motors ensures smoother, quieter operation.Key Advantages of Frameless Torque Motors

Compact Design: Frameless construction enables seamless integration into applications, allowing engineers to optimize space by embedding the motor directly into the machine structure. High Torque-to-Weight Ratio: Frameless torque motors deliver high torque relative to their compact size and weight, making them ideal for portable or weight-sensitive applications. Higher Efficiency and Reliability: The direct drive design of the frameless torque motors eliminates the need for gearboxes, belts or pulleys, resulting in reducing energy loss and lower maintenance requirements. Thermal Management Advantages: Frameless torque motors are ideal for custom cooling solutions. Without an external housing, engineers have the flexibility to design specialized cooling systems that more effectively manage heat. Customization Flexibility: Engineers can select or customize frameless motors to meet specific application needs. Key parameters such as diameter and winding configuration can be customized to suit a wide range of operating conditions.Common Applications of Frameless Torque Motors

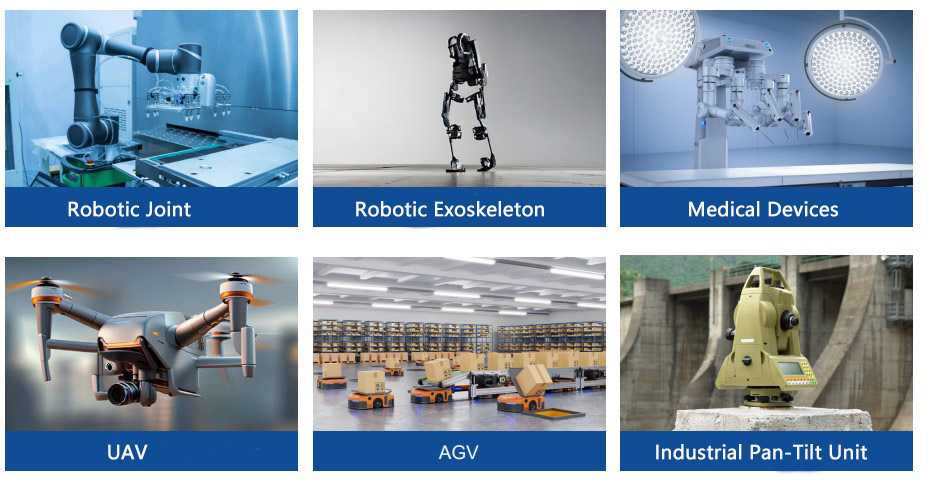

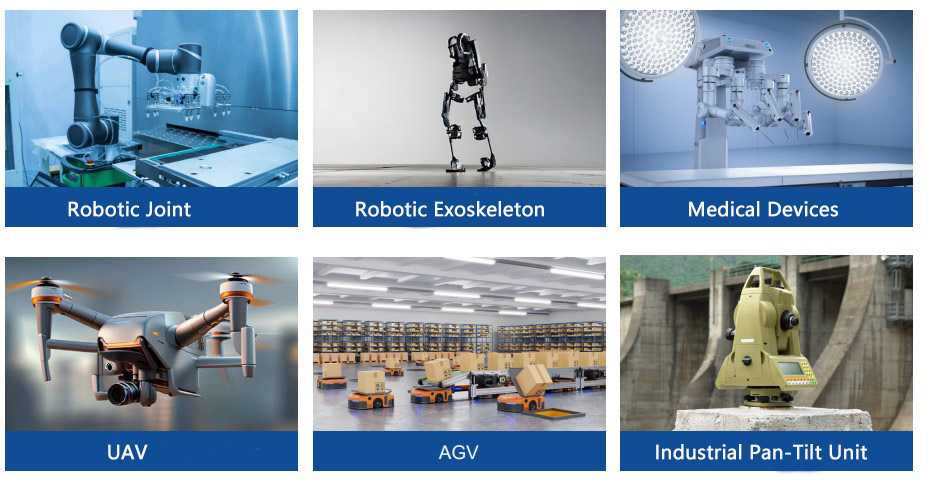

Frameless torque motors are a typical choice for applications requiring high precision, compact design and high torque output. Their primary application areas include: Robotics: With their high torque output, smooth motion and precise control, frameless torque motors serve as the core driving force behind industrial and service robots performing complex tasks. Aerospace: The lightweight and high power density characteristics make it suitable for aviation-grade application such as drone rotor drives and flight control systems. Medical Devices: Frameless motors are used in medical equipment to power robotic surgical systems and other precision instruments that demand compactness and accuracy. Industrial Automation: Frameless torque motors enable precise motion control in automated machinery and are especially well-suited for high-torque, low-speed applications (such as machine tool feed systems). Electric Vehicles (EVs): EV manufacturers utilize frameless torque motors to ensure an optimal balance between vehicle acceleration performance and energy utilization through high efficiency and high torque characteristics.

Robotics: With their high torque output, smooth motion and precise control, frameless torque motors serve as the core driving force behind industrial and service robots performing complex tasks. Aerospace: The lightweight and high power density characteristics make it suitable for aviation-grade application such as drone rotor drives and flight control systems. Medical Devices: Frameless motors are used in medical equipment to power robotic surgical systems and other precision instruments that demand compactness and accuracy. Industrial Automation: Frameless torque motors enable precise motion control in automated machinery and are especially well-suited for high-torque, low-speed applications (such as machine tool feed systems). Electric Vehicles (EVs): EV manufacturers utilize frameless torque motors to ensure an optimal balance between vehicle acceleration performance and energy utilization through high efficiency and high torque characteristics.