* Free shipping to North America and most of Europe for orders of $100 or more

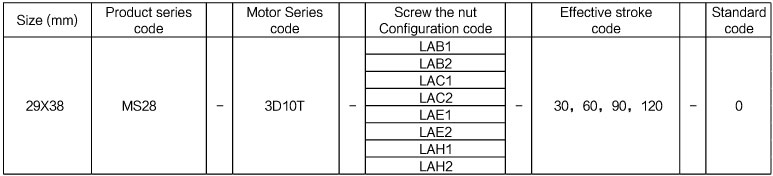

ID MS28 Series Linear Slides

MS28, Miniature linear slides has the characteristics of small volume, high effect, strong rigidity and high precision. At the same time, the selection is simple, the delivery period is short, and the installation is convenient.

● High precision

● High rigidity linear actuator

● Space saving

● Encoder and brake optional

● A range of lead screw and ball screw options

● High rigidity linear actuator

● Space saving

● Encoder and brake optional

● A range of lead screw and ball screw options

Brand Name: MOONS'

Price:

USD

423.0

-

456.0

EA

Payment Methods

Buyer Protection:

Buyer Protection:

MOONS' Linear Slides are designed to meet the needs of customers' compact structure. These products offer many advantages such as high integration, small size, quieter operation, stable product quality and lower cost.

MOONS' Linear Slides are designed to meet the needs of customers' compact structure. These products offer many advantages such as high integration, small size, quieter operation, stable product quality and lower cost.Not only provides the best performance but also easier to use.

- High RigidityThe ball linear guide uses four rows of arc grooves, with a contact angle of 45 degrees such as four rows of steel balls, so that the steel balls can achieve an ideal two-point contact structure, which can withstand the load from the up and down and left and right directions; when necessary, it can be pre-applied. Press to increase rigidity.

-

- High

- Performance

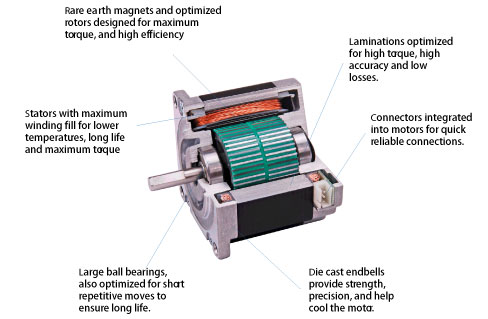

The stepper motor used in MOONS' linear module has undergone a series of optimizations and improvements, and its performance and value have been greatly improved:

-

- High

- Precision

An intuitive leap forward in nut design for lead screw applications, Constant Force Technology utilizes a constant force spring to apply a uniform pressure to the nut at all stages of the motion profile.

The repeat accuracy of standard nut drive can reach ±0.05mm;

The repeat accuracy of anti-backlash nut drive is higher than ±0.02mm.

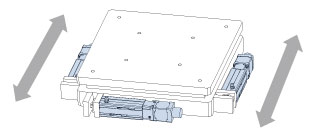

- applicationX/Y/θ axis adjustment of mobile platform

• Lens and mirror adjustment of microscope/telescope

• Table placement - Up and down movement of Z axis

• Semiconductor and LCD manufacturing equipment

• Automata and test equipment, etc.

MS Series Standard Models for stock

| Compare | Item | Price (USD) |

Buy Now |

|---|---|---|---|

|

|

MS28-3D10T-LAH1-30-0 | $423.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAH1-60-0 | $434.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAH1-90-0 | $456.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAE1-30-0 | $423.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAE1-60-0 | $434.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAE1-90-0 | $456.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAB1-30-0 | $423.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAB1-60-0 | $434.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAB1-90-0 | $456.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAC1-30-0 | $423.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAC1-60-0 | $434.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAC1-90-0 | $456.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAH2-30-0 | $427.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAH2-60-0 | $439.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAH2-90-0 | $450.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAE2-30-0 | $427.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAE2-60-0 | $439.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAE2-90-0 | $450.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAB2-30-0 | $427.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAB2-60-0 | $439.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAB2-90-0 | $450.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAC2-30-0 | $427.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAC2-60-0 | $439.00 |

Added to Your Shopping Cart

|

|

|

MS28-3D10T-LAC2-90-0 | $450.00 |

Added to Your Shopping Cart

|

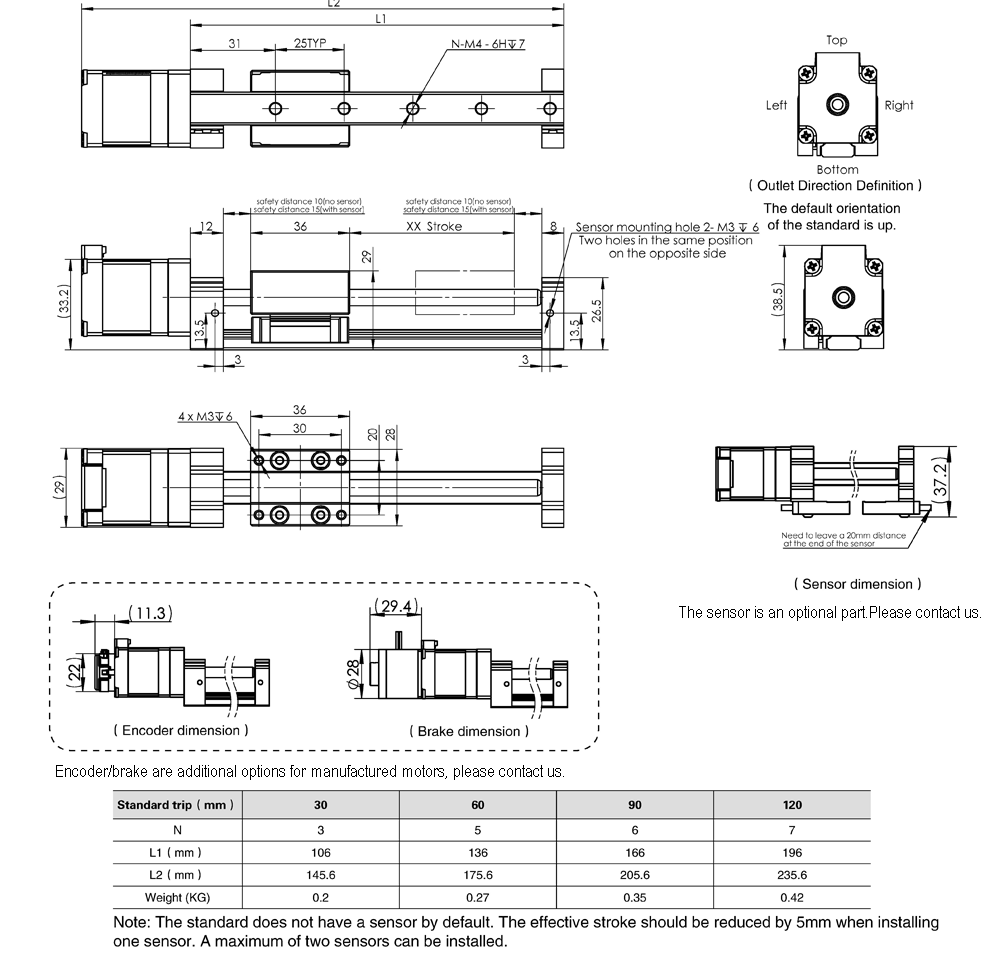

Dimensions

2D Drawings

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| MS28-3D10T-LAH1-30-0 2D drawing | 382 | ||

| MS28-3D10T-LAH1-90-0 2D drawing | 382 | ||

| MS28-3D10T-LAH1-60-0 2D drawing | 382 | ||

| MS28-3D10T-LAE1-60-0 2D drawing | 382 | ||

| MS28-3D10T-LAE1-90-0 2D drawing | 382 | ||

| MS28-3D10T-LAB2-60-0 2D drawing | 382 | ||

| MS28-3D10T-LAH2-30-0 2D drawing | 382 | ||

| MS28-3D10T-LAE1-30-0 2D drawing | 382 | ||

| MS28-3D10T-LAE2-30-0 2D drawing | 382 | ||

| MS28-3D10T-LAB1-30-0 2D drawing | 383 | ||

| MS28-3D10T-LAC1-60-0 2D drawing | 373 | ||

| MS28-3D10T-LAC1-30-0 2D drawing | 373 | ||

| MS28-3D10T-LAE2-90-0 2D drawing | 382 | ||

| MS28-3D10T-LAB1-60-0 2D drawing | 382 | ||

| MS28-3D10T-LAC2-30-0 2D drawing | 373 | ||

| MS28-3D10T-LAC2-90-0 2D drawing | 373 | ||

| MS28-3D10T-LAH2-60-0 2D drawing | 382 | ||

| MS28-3D10T-LAC2-60-0 2D drawing | 373 | ||

| MS28-3D10T-LAB1-90-0 2D drawing | 382 | ||

| MS28-3D10T-LAH2-90-0 2D drawing | 382 | ||

| MS28-3D10T-LAC1-90-0 2D drawing | 373 | ||

| MS28-3D10T-LAB2-90-0 2D drawing | 382 | ||

| MS28-3D10T-LAE2-60-0 2D drawing | 382 | ||

| MS28-3D10T-LAB2-30-0 2D drawing | 382 |

3D Model

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| MS28-3D10T-LAH1-30-0 3D model | STEP | 1716 | |

| MS28-3D10T-LAH1-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAH1-90-0 3D model | STEP | 7148 | |

| MS28-3D10T-LAE1-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAB1-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAE1-30-0 3D model | STEP | 1716 | |

| MS28-3D10T-LAC1-30-0 3D model | STEP | 1716 | |

| MS28-3D10T-LAE1-90-0 3D model | STEP | 7148 | |

| MS28-3D10T-LAB2-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAC2-90-0 3D model | STEP | 1668 | |

| MS28-3D10T-LAB1-30-0 3D model | STEP | 1716 | |

| MS28-3D10T-LAC1-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAE2-90-0 3D model | STEP | 1668 | |

| MS28-3D10T-LAC2-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAB1-90-0 3D model | STEP | 1668 | |

| MS28-3D10T-LAB2-90-0 3D model | STEP | 1668 | |

| MS28-3D10T-LAC2-30-0 3D model | STEP | 1716 | |

| MS28-3D10T-LAH2-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAC1-90-0 3D model | STEP | 1668 | |

| MS28-3D10T-LAH2-90-0 3D model | STEP | 1668 | |

| MS28-3D10T-LAH2-30-0 3D model | STEP | 1716 | |

| MS28-3D10T-LAE2-60-0 3D model | STEP | 1711 | |

| MS28-3D10T-LAE2-30-0 3D model | STEP | 1716 | |

| MS28-3D10T-LAB2-30-0 3D model | STEP | 1716 |

Catalog

| Title | Type | Size(KB) | Download |

|---|---|---|---|

| Linear Motion Product General Catalogue | 21843 |

Filter By Product Type

All ProductsDrives

Guidance on the usage of the linear sliders

Operating Frequency The transmission type of the linear sliders is sliding friction, so using the series in low operating frequency application is recommended. (Reference standard: 10 s/cycle, 8 h/day) Instructions for Vertical Installation When the slides are installed vertically, the slider may slip and cause damage to equipment or injury to personnel due to power failure. Therefore, self-locking force should be fully put into consideration when the slides are used vertically. If the self-locking force cannot overcome the free slip of the load, it would be necessary to add a brake.

For the sliders whose transmission type is sliding friction:

With a lead-to diameter ration less than 1:3, the slides are generally fully self-locking;

With a lead-to-diameter ratio of greater than 1:3, the slides have a certain self-locking force.

If you want to calculate the self-locking force, please contact the factory. Application Scenarios The structure of this series is simple, and the transmission type of the products is sliding friction. Its precision performances and impact resistance are not as good enough as ball screw type. The recommended maximum acceleration of the motor is less than 0.3 g. The maximum load is shown below. The sliding friction between the nut and the lead screw would generate a certain extent dusts and debris. If you need to use the slides in dust-free environment, please contact the factory. Repeatability The slides have two nut options: standard nut or anti-backlash nut.

The sliding friction between the nut and the lead screw would generate a certain extent dusts and debris. If you need to use the slides in dust-free environment, please contact the factory. Repeatability The slides have two nut options: standard nut or anti-backlash nut.

When using the standard nut, the repeatability of the slides is ±0.05mm.

When using the anti-backlash nut, the repeatability of the slides is ±0.02mm.

If you need precision products of better quality, please contact the factory. Lubrication Functions of grease: inhibit friction, reduce temperature rise, improve efficiency, eliminate noise, increase product life, etc.

Grease has been applied to the lead screw before deliver. Please contact the factory if the products don't need to be greased for special occasions.

(The reference grease: the base oil is synthetic oil, and the consistency grade is No.2 lithium-based grease.) Operating Environment Recommended Operating Environment:

Temperature range: 0-40℃,

Humidity 85% RH below (no condensation).

Acid-base free environment.

If you need to use the slides in special environment, please contact the factory. Installation reference surface requirements The installation reference surface must be ground or fine milling processing, in order to achieve the flatness of 0.05mm/m and surface roughness within Ra1.6, otherwise it may appear that the operation is not smooth, noise, jitter and other conditions. Smoothness Checking The module must be checked for smoothness after installation. When the motor is not energized, you can use a screwdriver or a torque meter with a single head inserted into the single slot on the end of the screw and turn the screw to check the rotational torque. Turn the screw to check the turning torque until the screw torque values are all close within the range of the slide travel. Since the slides would be greased before deliver, the user can use the module for the first time without greasing it again. Electricity debugging Please check the drive current carefully before running on power.

It is recommended that the drive current is set equal to or slightly less than the rated motor current. If the drive current is set too high, the motor may be burned out. If the drive current is set too low, the motor may not have enough torque and may lose steps or block the rotation. Please set a reasonable motor acceleration and deceleration speed (less than 0.3g is recommended). If the acceleration or deceleration is set too high, the motor may become blocked or lose steps.

Do not start the motor directly without setting the acceleration and deceleration. Storage and Safekeeping Please storage the slides horizontally and keep the environment dry.

The grease on the surface of the screw may evaporate and condense after long-term storage of the module, so it is recommended to store it for no more than three months.

For the sliders whose transmission type is sliding friction:

With a lead-to diameter ration less than 1:3, the slides are generally fully self-locking;

With a lead-to-diameter ratio of greater than 1:3, the slides have a certain self-locking force.

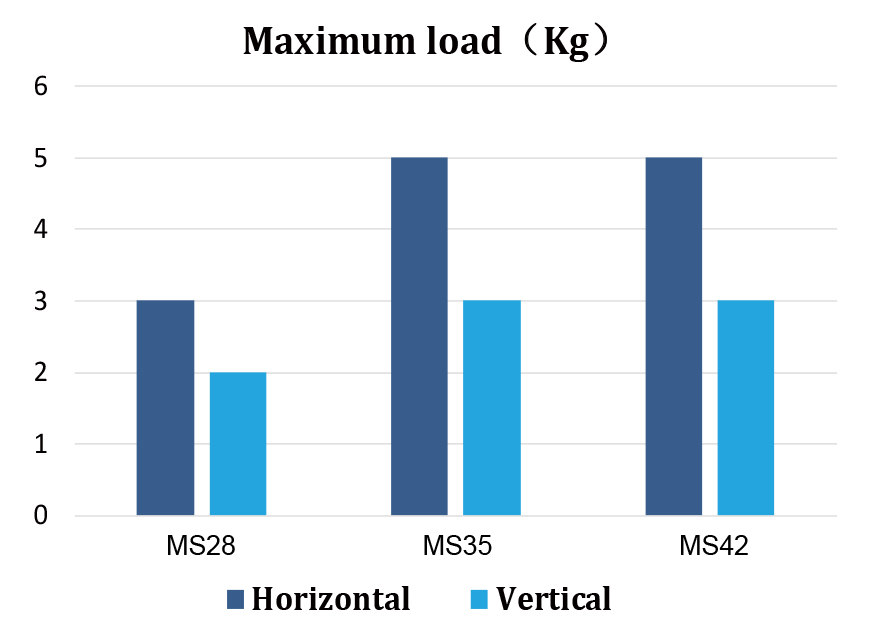

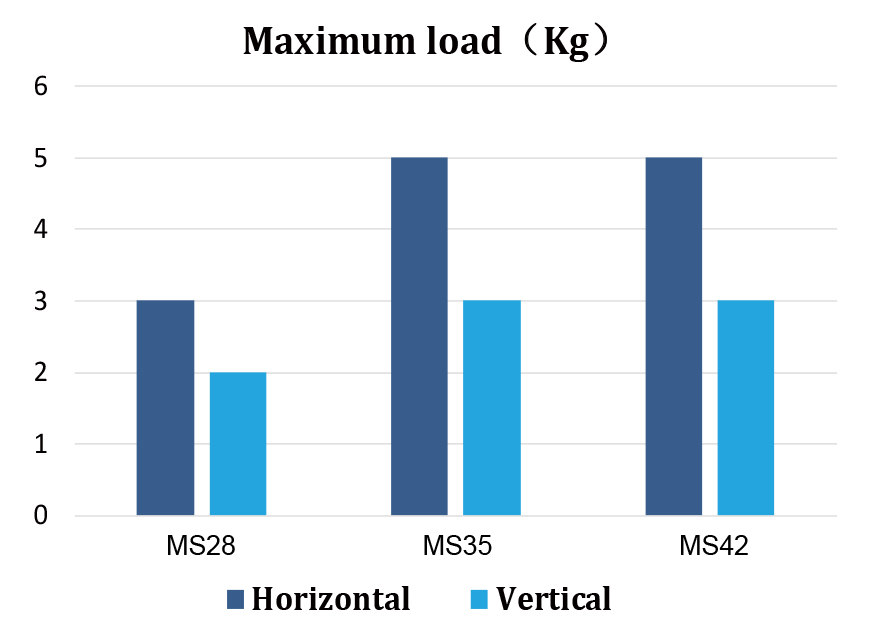

If you want to calculate the self-locking force, please contact the factory. Application Scenarios The structure of this series is simple, and the transmission type of the products is sliding friction. Its precision performances and impact resistance are not as good enough as ball screw type. The recommended maximum acceleration of the motor is less than 0.3 g. The maximum load is shown below.

When using the standard nut, the repeatability of the slides is ±0.05mm.

When using the anti-backlash nut, the repeatability of the slides is ±0.02mm.

If you need precision products of better quality, please contact the factory. Lubrication Functions of grease: inhibit friction, reduce temperature rise, improve efficiency, eliminate noise, increase product life, etc.

Grease has been applied to the lead screw before deliver. Please contact the factory if the products don't need to be greased for special occasions.

(The reference grease: the base oil is synthetic oil, and the consistency grade is No.2 lithium-based grease.) Operating Environment Recommended Operating Environment:

Temperature range: 0-40℃,

Humidity 85% RH below (no condensation).

Acid-base free environment.

If you need to use the slides in special environment, please contact the factory. Installation reference surface requirements The installation reference surface must be ground or fine milling processing, in order to achieve the flatness of 0.05mm/m and surface roughness within Ra1.6, otherwise it may appear that the operation is not smooth, noise, jitter and other conditions. Smoothness Checking The module must be checked for smoothness after installation. When the motor is not energized, you can use a screwdriver or a torque meter with a single head inserted into the single slot on the end of the screw and turn the screw to check the rotational torque. Turn the screw to check the turning torque until the screw torque values are all close within the range of the slide travel. Since the slides would be greased before deliver, the user can use the module for the first time without greasing it again. Electricity debugging Please check the drive current carefully before running on power.

It is recommended that the drive current is set equal to or slightly less than the rated motor current. If the drive current is set too high, the motor may be burned out. If the drive current is set too low, the motor may not have enough torque and may lose steps or block the rotation. Please set a reasonable motor acceleration and deceleration speed (less than 0.3g is recommended). If the acceleration or deceleration is set too high, the motor may become blocked or lose steps.

Do not start the motor directly without setting the acceleration and deceleration. Storage and Safekeeping Please storage the slides horizontally and keep the environment dry.

The grease on the surface of the screw may evaporate and condense after long-term storage of the module, so it is recommended to store it for no more than three months.

Delivery & Packaging

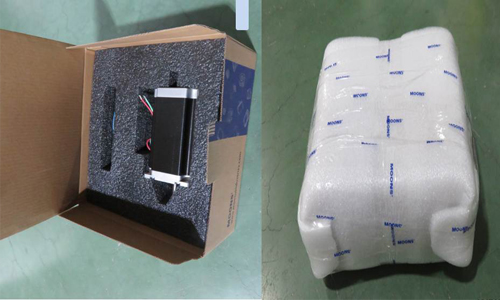

Ensure your ordered products are always safely packaged from easy click to fast delivery to your handsProfessional Product Label

Considering all possible harsh application environments, MOONS' specially designed labels for each product, which pass water-resistance test, durability rub test, high temperature resistance and corrosion resistance tests.Besides, our product labels are attached with QR code linking to product details, which is convenient for clients to view the detail product page with their mobile phones.

Note: This label design is suitable for products of stepper motor.

(Professional packing box and unique appearance design)

(Single item packed with EPE)

(Multi-products packed with another box)

Safely Packaging

In order to ensure your shipments withstand the long trip and arrive safely and intact, MOONS' specially designed Individual package to pass the drop test with its stable structure.Besides,the package is made from recyclable materials, providing you with professional safety delivery.

Whether just single item or multi-products the clients buy, all products are packed twice to avoid the damage further.

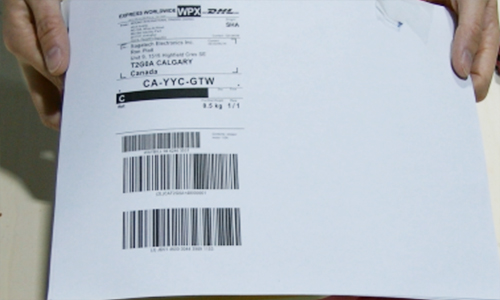

Shipping Visualization

For each case, products are carefully packed by experienced warehouse staff and the key processes are recorded by photos, which are then posted on our website, so that clients could clearly know the packing process and logistics status after placing order.

(Product in the box)

(Add the invoice)

(Label the commodity)

(The logistics waybill attached)

Fast Delivery

Fast Cross-Border DeliveryMOONS' chooses DHL as our main international express shipping partner. As the world's leading logistics specialist, DHL provides our customers with fast and professional inter- national door-to-door delivery service.

Estimated Delivery Time: e.g. China-USA major cities 3 business days.

Professional

Warehouse Management

Free Exchange

Free Exchange