4X Quadrature Decoding Principle of Encoders

An encoder is a sensor used to measure mechanical rotation or linear displacement, converting the position or speed of a moving part into a series of electrical signals. 4X Quadrature decoding is a signal processing technique that enhances the resolution of an incremental encoder. For example, a grating encoder has N grids per revolution. In theory, the motor rotating the encoder shaft one revolution would only output N pulses. By applying 4X quadrature decoding, N*4 pulses can be output per revolution. Therefore, 4X quadrature decoding increases the encoder's native resolution by four.  The 4X decoding technique is applicable only to incremental encoders, which output two orthogonal signals (A phase and B phase) with a phase difference of 90 degrees, and generate a fixed number of pulses (PPR, pulses per revolution) per rotation. The characteristics of its orthogonal signal are: A phase leads B phase by 90 degrees in forward rotation, and B phase leads A phase by 90 degrees in reverse rotation.

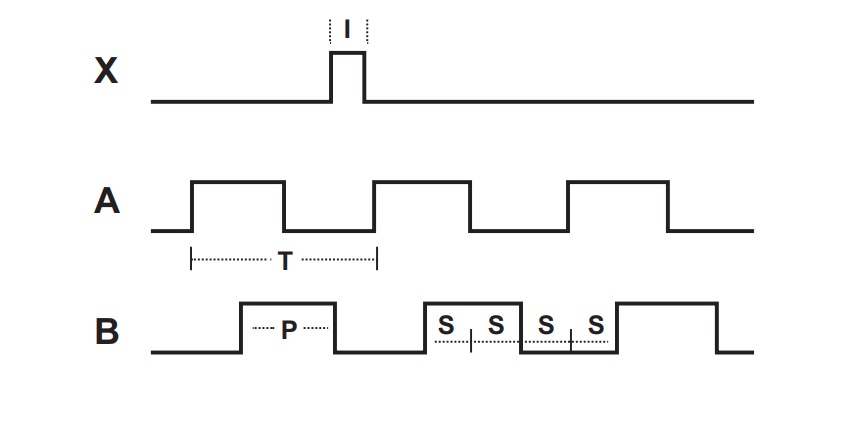

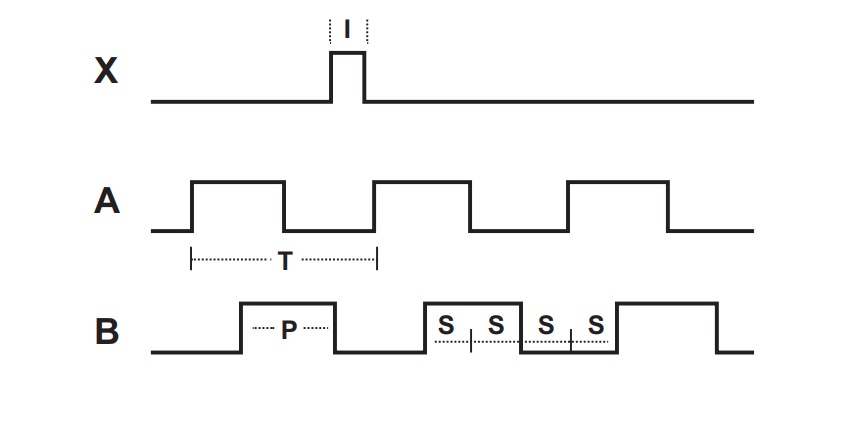

The 4X decoding technique is applicable only to incremental encoders, which output two orthogonal signals (A phase and B phase) with a phase difference of 90 degrees, and generate a fixed number of pulses (PPR, pulses per revolution) per rotation. The characteristics of its orthogonal signal are: A phase leads B phase by 90 degrees in forward rotation, and B phase leads A phase by 90 degrees in reverse rotation.

4X Quadrature Decoding Principle of Encoders can be understood from the following three aspects: Edge detection: Each full cycle of the quadrature signals (A and B combined) contains four edges (rising edge of A, rising edge of B, falling edge of A, falling edge of B). State combination: These four edges correspond to four unique states (A↑, B↑, A↓, B↓). Each edge triggers a count increment, quadrupling the resolution compared to the base PPR. Direction judgment: The direction of movement is determined by comparing the logic level of the other channel at the moment an edge occurs on one channel. (For example, an A rising edge with B low indicates forward rotation; with B high indicates reverse rotation). Implementation of 4X quadrature decoding includes: Hardware-based: Digital logic components (e.g., XOR gates, D flip-flops) to detect signal edges and generate corresponding counting pulses. Software-based: Using a microcontroller or FPGA to capture edge interrupts, employing a state machine to determine direction, and accumulate the count value. Debouncing: To prevent false triggering caused by signal noise or jitter, debouncing techniques are applied—either through hardware filtering circuits or software-based delay mechanisms.

4X Quadrature Decoding Principle Example Process Forward rotation: - A↑ → B=0 → count+1 - B↑ → A=1 → count+1 - A↓ → B=1 → count+1 - B↓ → A=0 → count+1 When reversing: - B↑ → A=0 → count-1 - A↑ → B=1 → count-1 - B↓ → A=1 → count-1 - A↓ → B=0 → count-1

Note: Special attention should be given to signal quality and processing speed: The 90° phase relationship between Channels A and B must be strictly maintained, and signal jitter must be minimized. Additionally, ensure the hardware circuit or software algorithm has sufficient processing speed to respond to signal edge changes in real-time, preventing missed counts.

The application scenarios of encoder quadruple frequency technology include high-precision control (such as CNC machine tools, robot joints, and other scenarios that require subtle position feedback) and low-cost solutions (replacing high-resolution encoders with quadruple frequency to reduce system costs). The advantage of this technology is its ability to quadruple measurement resolution without modifying the physical structure of the encoder. However, the challenge is that signal quality (such as noise, phase error) may affect counting accuracy, requiring filtering or calibration measures. 4X quadrature decoding enhances the effective resolution of an encoder by utilizing all four edges of the orthogonal signals (rising and falling edges of both channels A and B). It is a widely used technique in industrial control systems to improve positioning accuracy without changing the hardware.

The 4X decoding technique is applicable only to incremental encoders, which output two orthogonal signals (A phase and B phase) with a phase difference of 90 degrees, and generate a fixed number of pulses (PPR, pulses per revolution) per rotation. The characteristics of its orthogonal signal are: A phase leads B phase by 90 degrees in forward rotation, and B phase leads A phase by 90 degrees in reverse rotation.

The 4X decoding technique is applicable only to incremental encoders, which output two orthogonal signals (A phase and B phase) with a phase difference of 90 degrees, and generate a fixed number of pulses (PPR, pulses per revolution) per rotation. The characteristics of its orthogonal signal are: A phase leads B phase by 90 degrees in forward rotation, and B phase leads A phase by 90 degrees in reverse rotation. 4X Quadrature Decoding Principle of Encoders can be understood from the following three aspects: Edge detection: Each full cycle of the quadrature signals (A and B combined) contains four edges (rising edge of A, rising edge of B, falling edge of A, falling edge of B). State combination: These four edges correspond to four unique states (A↑, B↑, A↓, B↓). Each edge triggers a count increment, quadrupling the resolution compared to the base PPR. Direction judgment: The direction of movement is determined by comparing the logic level of the other channel at the moment an edge occurs on one channel. (For example, an A rising edge with B low indicates forward rotation; with B high indicates reverse rotation). Implementation of 4X quadrature decoding includes: Hardware-based: Digital logic components (e.g., XOR gates, D flip-flops) to detect signal edges and generate corresponding counting pulses. Software-based: Using a microcontroller or FPGA to capture edge interrupts, employing a state machine to determine direction, and accumulate the count value. Debouncing: To prevent false triggering caused by signal noise or jitter, debouncing techniques are applied—either through hardware filtering circuits or software-based delay mechanisms.

4X Quadrature Decoding Principle Example Process Forward rotation: - A↑ → B=0 → count+1 - B↑ → A=1 → count+1 - A↓ → B=1 → count+1 - B↓ → A=0 → count+1 When reversing: - B↑ → A=0 → count-1 - A↑ → B=1 → count-1 - B↓ → A=1 → count-1 - A↓ → B=0 → count-1

Note: Special attention should be given to signal quality and processing speed: The 90° phase relationship between Channels A and B must be strictly maintained, and signal jitter must be minimized. Additionally, ensure the hardware circuit or software algorithm has sufficient processing speed to respond to signal edge changes in real-time, preventing missed counts.

The application scenarios of encoder quadruple frequency technology include high-precision control (such as CNC machine tools, robot joints, and other scenarios that require subtle position feedback) and low-cost solutions (replacing high-resolution encoders with quadruple frequency to reduce system costs). The advantage of this technology is its ability to quadruple measurement resolution without modifying the physical structure of the encoder. However, the challenge is that signal quality (such as noise, phase error) may affect counting accuracy, requiring filtering or calibration measures. 4X quadrature decoding enhances the effective resolution of an encoder by utilizing all four edges of the orthogonal signals (rising and falling edges of both channels A and B). It is a widely used technique in industrial control systems to improve positioning accuracy without changing the hardware.