- Home

- Technical College

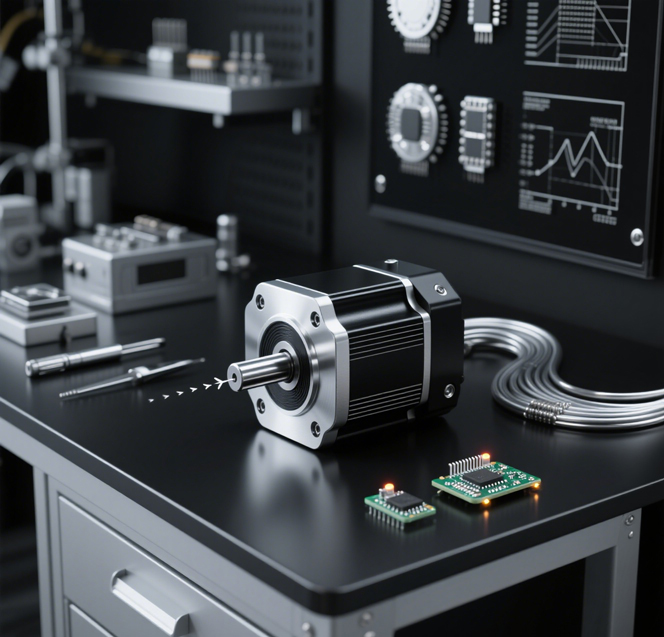

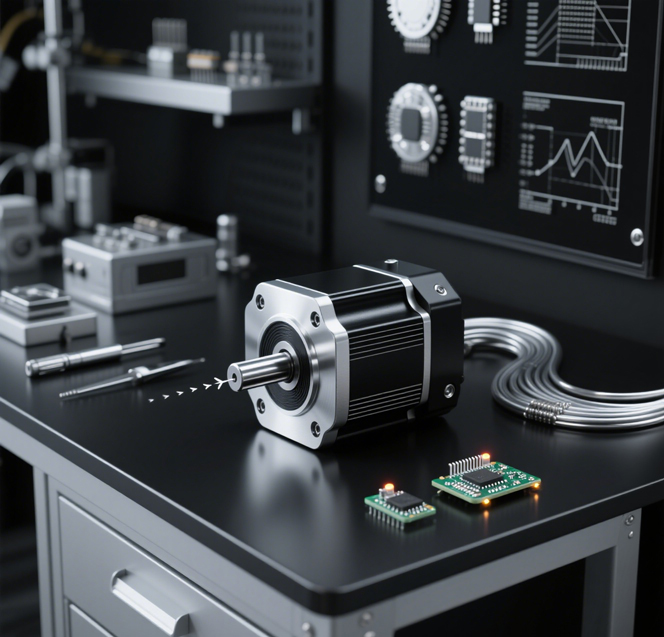

- STEPPER MOTORS

- Possible Causes of Sudden Reversal in a Stepper Motor During Normal Operation

Possible Causes of Sudden Reversal in a Stepper Motor During Normal Operation

Sudden reversal of a stepper motor during normal operation may be causes by various factors, including interference with the direction signal (DIR), driver malfunction, or incorrect driver parameter settings. This article outlines the common causes and corresponding solutions for such issues, providing a reference for troubleshooting.  1. DIR signal interference or abnormality may cause the stepper motor to suddenly reverse. Analysis indicates that the direct cause of the stepper motor's sudden reversal is an abnormal direction signal (DIR). This can result from electromagnetic interference, poor contact within the controller hardware, or logic errors in the control program. There issues may cause a sudden flip in the Dir signal level, leading to an unexpected reversal of motor movement. To address this issue, the following areas should be checked: Wiring integrity: Verify whether the DIR signal wire is loose, poorly connected, or unshielded, any of which may lead to signal interference. Source of interference: Check for nearby high-power equipment (such as inverters or motors) that may be generating electromagnetic interference. Consider adding ferrite cores or replacing the wiring with twisted-pair shielded cables. Signal level monitoring: Use an oscilloscope to monitor the DIR signal and check for any unexpected level changes or glitches.

1. DIR signal interference or abnormality may cause the stepper motor to suddenly reverse. Analysis indicates that the direct cause of the stepper motor's sudden reversal is an abnormal direction signal (DIR). This can result from electromagnetic interference, poor contact within the controller hardware, or logic errors in the control program. There issues may cause a sudden flip in the Dir signal level, leading to an unexpected reversal of motor movement. To address this issue, the following areas should be checked: Wiring integrity: Verify whether the DIR signal wire is loose, poorly connected, or unshielded, any of which may lead to signal interference. Source of interference: Check for nearby high-power equipment (such as inverters or motors) that may be generating electromagnetic interference. Consider adding ferrite cores or replacing the wiring with twisted-pair shielded cables. Signal level monitoring: Use an oscilloscope to monitor the DIR signal and check for any unexpected level changes or glitches.

2. Driver malfunction or incorrect parameter settings may cause the stepper motor to suddenly reverse. Incorrect driver subdivision settings, improper current parameters, or internal circuit instability can all lead to sudden reversal of the stepper motor. The following checks are recommended: Subdivision settings: A mismatch between the driver's microstepping setting and the controller configuration can result in phase errors. Current settings: If the drive current is set too low, the motor may lose steps. When the driver attempts to "correct" these errors, it may trigger an unexpected reversal. Driver malfunction: Test with a replacement driver to rule out hardware faults.

3. Logic errors in the control program may cause the stepper motor to suddenly reverse. A logic error in the direction control section of the code can cause the stepper motor to suddenly reverse, such as an interrupt conflicts, variable overflows, and signal competition, etc. To determine whether this is the cause, consider checking the following three aspects: Direction variable anomalies: Check whether the variable controlling the direction in the code has been accidentally modified (such as conflict between the interrupt function and the main loop); Signal timing: Whether the switching timing of the STEP pulse and the DIR signal meets the requirements of the driver (usually DIR needs to be stabilized a few microseconds in advance); Step loss compensation: In some closed-loop control systems, the algorithm may automatically reverse the motor to correct positioning errors when step loss is detected.

4. Power supply issues can also lead to sudden reversal of the stepper motor. If the power supply voltage is unstable or the power capacity is insufficient, the motor output torque may decrease, causing step loss under sudden load changes, potentially resulting in unexpected reversal of the stepper motor. Check for voltage fluctuations and proper power matching. Voltage fluctuation: Use a multimeter to monitor the power supply voltage, observe whether a voltage drop occurs during sudden load changes. Power matching: Ensure the power supply is greater than 1.5 times the rated power of the motor during frequent start-stop cycles.

5. Sudden changes in mechanical load or system resonance may cause the stepper motor to reverse unexpectedly. When the mechanical structure jams, the load changes abruptly, or the system enters resonance, the stepper motor may lose steps, and the driver may misjudge the motor's position, resulting in a sudden and unexpected reversal. It is important to inspect the system from three aspects: mechanical resistance, resonance point, and overload protection. Mechanical resistance: Check whether the transmission parts such as guide rails and lead screws are well lubricated and free from jamming or binding. Resonance: Adjust the driver's microstepping settings or acceleration and deceleration curve to avoid operating within the resonance speed range. Overload protection: Appropriately increase the driver current (not exceeding the motor rated value).

6. Encoder or feedback signal abnormalities in a closed-loop stepper motor can also cause sudden reversal. In closed-loop control systems, interference with the encoder signal can cause the controller to misinterpret the motor's position, leading to incorrect directional adjustments and a sudden reversal of the stepper motor. To address this issue, both encoder wiring and feedback logic should be checked: Encoder wiring: Ensure the encoder signal cables are properly shielded and avoid parallel connection with the power line. Feedback logic: Verify whether there is an incorrect position correction strategy in the closed-loop control algorithm.

7. Environmental factors can also lead to sudden reversal of the stepper motor. High temperature may degrade the performance of the driver or motor, while strong vibrations can loosen wiring or cause false triggering of sensors. Therefore, it is important to consider the potential impact of environmental conditions on system stability.

To diagnose the cause of a sudden reversal during normal operation of a stepper motor, it is recommended to follow the steps outlined below: 1. Simplify the system: Remove the load and test whether the reversal still occurs in the no-load state to determine whether it is a mechanical problem. 2. Monitor control signals: Use an oscilloscope to capture the DIR and STEP signals and observe whether there is any abnormal jump at the moment of reversal. 3. Isolate electrical interference: Temporarily use an independent power supply, away from the interference source, and test whether the problem disappears. 4. Update firmware/driver: Check whether the controller or driver has firmware updates and fix potential logic defects. 5. Replacement test: Replace the motor, driver, and controller to eliminate hardware faults one by one. The above troubleshooting can typically help you identify the root cause of the issue. If the problem persists, it is recommended to provide detailed information, such as the specific model, wiring diagram, and relevant portions of the control code to the equipment supplier for further analysis and support.

1. DIR signal interference or abnormality may cause the stepper motor to suddenly reverse. Analysis indicates that the direct cause of the stepper motor's sudden reversal is an abnormal direction signal (DIR). This can result from electromagnetic interference, poor contact within the controller hardware, or logic errors in the control program. There issues may cause a sudden flip in the Dir signal level, leading to an unexpected reversal of motor movement. To address this issue, the following areas should be checked: Wiring integrity: Verify whether the DIR signal wire is loose, poorly connected, or unshielded, any of which may lead to signal interference. Source of interference: Check for nearby high-power equipment (such as inverters or motors) that may be generating electromagnetic interference. Consider adding ferrite cores or replacing the wiring with twisted-pair shielded cables. Signal level monitoring: Use an oscilloscope to monitor the DIR signal and check for any unexpected level changes or glitches.

1. DIR signal interference or abnormality may cause the stepper motor to suddenly reverse. Analysis indicates that the direct cause of the stepper motor's sudden reversal is an abnormal direction signal (DIR). This can result from electromagnetic interference, poor contact within the controller hardware, or logic errors in the control program. There issues may cause a sudden flip in the Dir signal level, leading to an unexpected reversal of motor movement. To address this issue, the following areas should be checked: Wiring integrity: Verify whether the DIR signal wire is loose, poorly connected, or unshielded, any of which may lead to signal interference. Source of interference: Check for nearby high-power equipment (such as inverters or motors) that may be generating electromagnetic interference. Consider adding ferrite cores or replacing the wiring with twisted-pair shielded cables. Signal level monitoring: Use an oscilloscope to monitor the DIR signal and check for any unexpected level changes or glitches. 2. Driver malfunction or incorrect parameter settings may cause the stepper motor to suddenly reverse. Incorrect driver subdivision settings, improper current parameters, or internal circuit instability can all lead to sudden reversal of the stepper motor. The following checks are recommended: Subdivision settings: A mismatch between the driver's microstepping setting and the controller configuration can result in phase errors. Current settings: If the drive current is set too low, the motor may lose steps. When the driver attempts to "correct" these errors, it may trigger an unexpected reversal. Driver malfunction: Test with a replacement driver to rule out hardware faults.

3. Logic errors in the control program may cause the stepper motor to suddenly reverse. A logic error in the direction control section of the code can cause the stepper motor to suddenly reverse, such as an interrupt conflicts, variable overflows, and signal competition, etc. To determine whether this is the cause, consider checking the following three aspects: Direction variable anomalies: Check whether the variable controlling the direction in the code has been accidentally modified (such as conflict between the interrupt function and the main loop); Signal timing: Whether the switching timing of the STEP pulse and the DIR signal meets the requirements of the driver (usually DIR needs to be stabilized a few microseconds in advance); Step loss compensation: In some closed-loop control systems, the algorithm may automatically reverse the motor to correct positioning errors when step loss is detected.

4. Power supply issues can also lead to sudden reversal of the stepper motor. If the power supply voltage is unstable or the power capacity is insufficient, the motor output torque may decrease, causing step loss under sudden load changes, potentially resulting in unexpected reversal of the stepper motor. Check for voltage fluctuations and proper power matching. Voltage fluctuation: Use a multimeter to monitor the power supply voltage, observe whether a voltage drop occurs during sudden load changes. Power matching: Ensure the power supply is greater than 1.5 times the rated power of the motor during frequent start-stop cycles.

5. Sudden changes in mechanical load or system resonance may cause the stepper motor to reverse unexpectedly. When the mechanical structure jams, the load changes abruptly, or the system enters resonance, the stepper motor may lose steps, and the driver may misjudge the motor's position, resulting in a sudden and unexpected reversal. It is important to inspect the system from three aspects: mechanical resistance, resonance point, and overload protection. Mechanical resistance: Check whether the transmission parts such as guide rails and lead screws are well lubricated and free from jamming or binding. Resonance: Adjust the driver's microstepping settings or acceleration and deceleration curve to avoid operating within the resonance speed range. Overload protection: Appropriately increase the driver current (not exceeding the motor rated value).

6. Encoder or feedback signal abnormalities in a closed-loop stepper motor can also cause sudden reversal. In closed-loop control systems, interference with the encoder signal can cause the controller to misinterpret the motor's position, leading to incorrect directional adjustments and a sudden reversal of the stepper motor. To address this issue, both encoder wiring and feedback logic should be checked: Encoder wiring: Ensure the encoder signal cables are properly shielded and avoid parallel connection with the power line. Feedback logic: Verify whether there is an incorrect position correction strategy in the closed-loop control algorithm.

7. Environmental factors can also lead to sudden reversal of the stepper motor. High temperature may degrade the performance of the driver or motor, while strong vibrations can loosen wiring or cause false triggering of sensors. Therefore, it is important to consider the potential impact of environmental conditions on system stability.

To diagnose the cause of a sudden reversal during normal operation of a stepper motor, it is recommended to follow the steps outlined below: 1. Simplify the system: Remove the load and test whether the reversal still occurs in the no-load state to determine whether it is a mechanical problem. 2. Monitor control signals: Use an oscilloscope to capture the DIR and STEP signals and observe whether there is any abnormal jump at the moment of reversal. 3. Isolate electrical interference: Temporarily use an independent power supply, away from the interference source, and test whether the problem disappears. 4. Update firmware/driver: Check whether the controller or driver has firmware updates and fix potential logic defects. 5. Replacement test: Replace the motor, driver, and controller to eliminate hardware faults one by one. The above troubleshooting can typically help you identify the root cause of the issue. If the problem persists, it is recommended to provide detailed information, such as the specific model, wiring diagram, and relevant portions of the control code to the equipment supplier for further analysis and support.