Motor Speed Calculation Formula

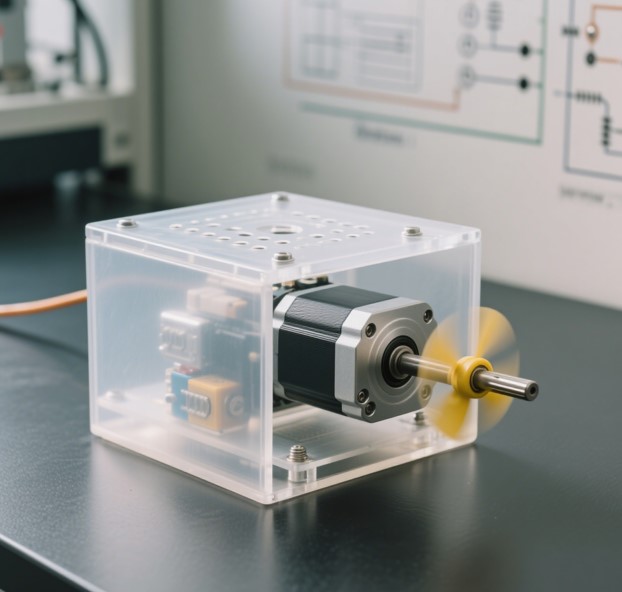

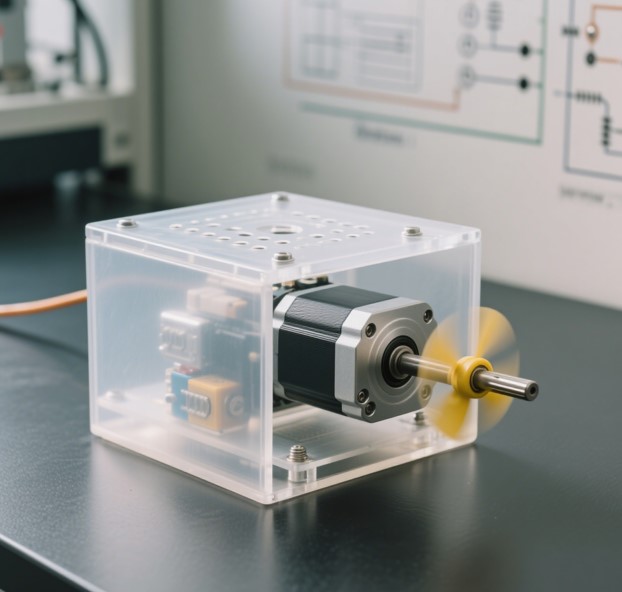

Motor speed refers to the number of revolutions completed by the motor shaft within a specified period, typically expressed in RPM (revolutions per minute). The rotational speed determines the motor's output speed, which is a critical factor in its performance. The motor speed calculation formula can be used for fault diagnosis. By comparing the theoretical speed with the actual speed, significant deviation may indicate issues such as winding short circuit and bearing failures. The speed formula can help identify and pinpoint the root causes of such faults. The formula for calculating motor speed varies depending on the type and operating principle of the motor, mainly including AC synchronous motors and DC motors. Understanding these formulars makes it easier to select a motor with the appropriate speed for a given application.