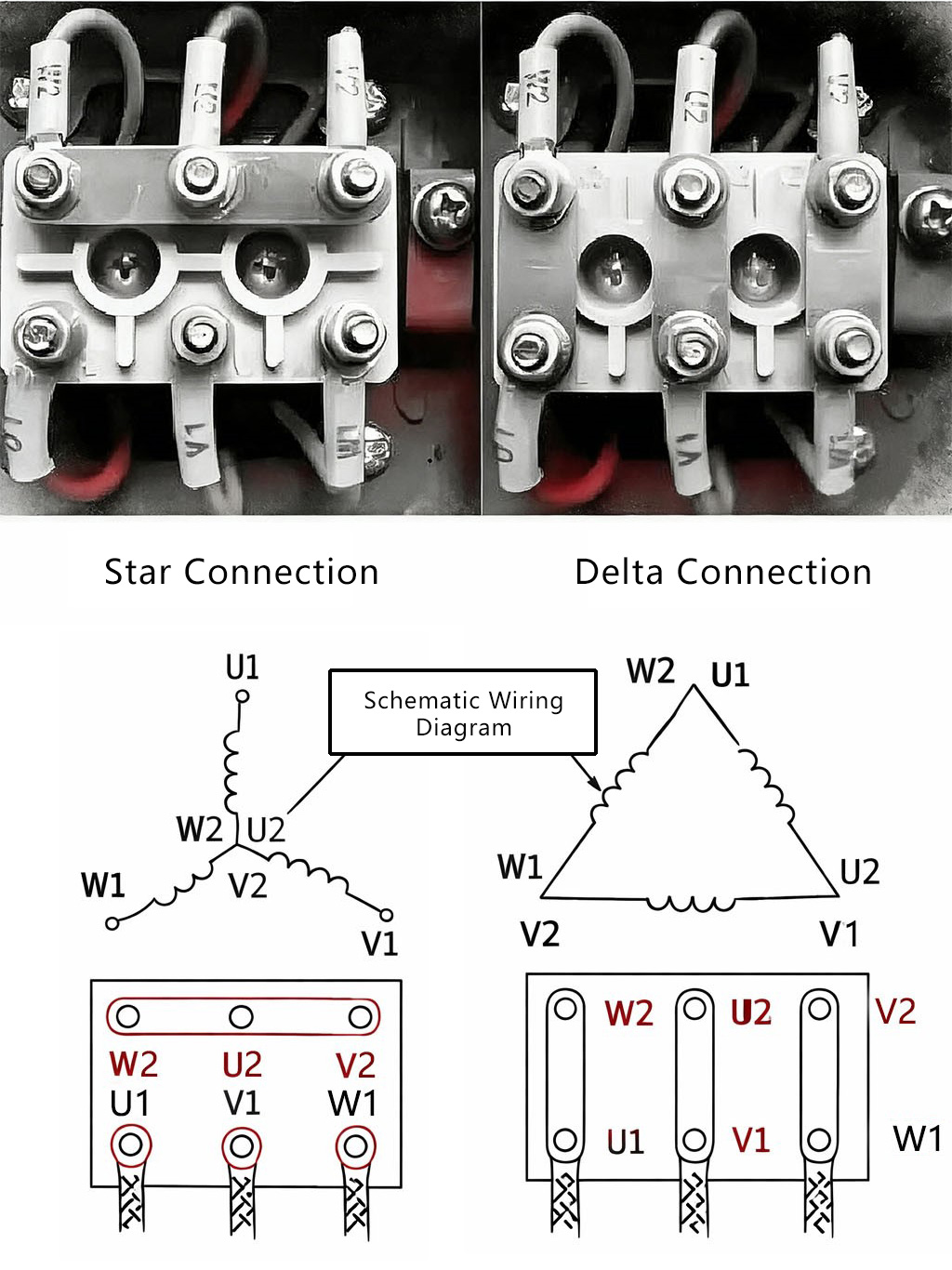

Differences Between Star and Delta Motor Connections

A motor can be connected in either a star or delta configuration, with the main differences reflected in operating voltage, current, output power, starting characteristics, and application scenarios. An overall comparison is provided in the table above.

| Characteristic Comparison | Star Connection (Y) | Delta Connection (Δ) |

| Winding Connection Method | The ends of the three-phase windings are connected together to form a neutral point, while the other ends are connected to the three-phase power supply. | The three-phase windings are connected end-to-end to form a closed delta, with each junction connected to the three-phase power supply. |

| Winding Voltage | Phase voltage (equal to the line voltage divided by √3) | Line voltage (equal to the supply line voltage) |

| Winding Current | Equal to the line current | Equal to the line current divided by √3 |

| Starting Current | Lower (approximately one-third of the delta starting current) | Higher (direct full-voltage starting) |

| Starting Torque | Lower (approximately one-third of the starting torque under delta connection) | Higher (direct-on-line starting) |

| Output Power | Lower (approximately 1/√3 of the rated power) | Higher (up to the motor's rated power) |

| Key Advantages | Smooth starting, minimal impact on the power grid and mechanical system; lower insulation stress on the windings. | Capable of delivering the motor's rated power and torque; slightly higher efficiency. |

| Key Disadvantages | Unable to deliver the motor's maximum rated power and torque. | High starting current and mechanical stress; the windings are subjected to higher voltage. |

| Typical Applications | Reduced-voltage starting (large motors start with a Y connection and then switch to Δ operation); long-term light-load operation for energy savings; applications on higher-voltage power grids (e.g., using a 660V/380V motor on a 380V supply). | Normal motor operation; applications requiring high starting torque under light-load conditions (e.g., belt conveyors); low-voltage power grids (e.g., using a 220V/380V motor on a 220V supply). |

Difference Diagram of Star and Delta Motor Connections

The following section details the differences between star and delta motor connections, beginning with the core principles.

I. Relationship Between Voltage and Current (Key Difference)

The relationship between voltage and current is fundamental to understanding the differences between star and delta connections and serves as the key basis for engineering decisions. In a star connection (Y connection), one end of the three-phase windings is joined to form a neutral point, while the other ends are connected to the three-phase power supply. In this configuration, the voltage across each phase winding equals the line voltage divided by √3. For example, when the line voltage is 380V, each phase winding experiences approximately 220V, and the phase current is equal to the line current. Thus, in a star connection, the winding voltage is lower, while the overall current remains comparable to the line current, resulting in a reduced starting current.

In contrast, a delta connection (Δ connection) links the three-phase windings end-to-end to form a closed loop, with each junction connected to the power supply. Each phase winding directly experiences the line voltage; thus, under a 380V supply, the voltage across each winding is 380V. Due to the vector relationship of the currents, the phase current in each winding equals the line current divided by √3, meaning the winding current is lower than the line current. As a result, delta connections subject the windings to higher voltage while keeping the current relatively low, making them better suited for full-load operation.

To better visualize the two connection methods, we can use three identical resistors as an analogy. In a star connection, the resistors are joined at one end, while the other ends are connected to three phase lines, with each resistor experiencing a lower voltage. In contrast, a delta connection links the resistors end-to-end to form a closed loop, with each junction connected to the power supply and each resistor subjected to the full line voltage. This analogy clearly illustrates the fundamental differences between star and delta connections in voltage and current distribution, and also explains their differing starting characteristics and suitable application scenarios.

II. Key Differences in Startup Characteristics

When a motor starts, the rotor is stationary, so the back electromotive force (EMF) is zero, resulting in the maximum current, called the starting current. In a star connection, the phase winding voltage is only 1/√3 of that in a delta connection; according to Ohm's law, the starting current is therefore roughly one-third of that in a delta-started motor. Since the starting torque is proportional to the square of the applied voltage, a star-started motor also develops approximately one-third of the torque of a delta-started motor.

This characteristic makes star starting particularly suitable for high-power motors or applications where limiting startup stress is important, as it reduces the starting current's impact on the power grid and lowers mechanical stress on the transmission system. In contrast, delta starting provides higher starting torque but draws a much larger current, imposing greater stress on both the power grid and the equipment. Consequently, delta starting is typically used only for smaller motors or when the power supply can handle the higher startup load.

III. Power Output Differences

A motor's rated power is specified for its rated voltage and current. For the same motor, the connection method significantly affects the actual output power. In a delta connection, the windings are subjected to the full rated line voltage, allowing the motor to deliver its rated power—for example, 4 kW. In contrast, with a star connection, the voltage applied to each phase winding is only 1/√3 of the line voltage. As a result, the output power decreases proportionally to about 0.577 times the rated power, i.e., approximately 2.3 kW.

Therefore, a delta connection is typically chosen when the load is high and full power output is required. During startup or in operating conditions with lower power demands, a star connection can reduce the starting current and lower stress on the power grid and mechanical system. The difference in power output is a key factor to consider when selecting between star and delta connections in an application.

Practical Applications: Star-Delta Reduced-Voltage Starting

Star-delta reduced-voltage starting takes advantage of the differences in voltage, current, and torque between star and delta connections to achieve smooth starting of high-power motors. For three-phase asynchronous motors with rated power typically above 7.5 kW, direct full-voltage starting would draw a very large starting current, imposing significant stress on the power grid and mechanical systems. Therefore, the reduced-voltage star-delta starting method, which begins in a star configuration and then switches to delta, is widely adopted.

During startup, the motor is connected in a star configuration via the starter, with each phase winding experiencing only 1/√3 of the line voltage. As a result, the starting current and torque are roughly one-third of those in a full-voltage start, resulting in a smooth start and lower stress on the power grid and mechanical system. Once the motor reaches near its rated speed, the starter automatically switches to a delta configuration via a time or current relay, subjecting the windings to full voltage. The motor then operates at its rated power and torque, entering normal operation.

It is important to note that star-delta reduced-voltage starting is only suitable for light-load or no-load equipment, such as water pumps and fans, because star starting produces lower torque, which is insufficient to start heavily loaded equipment. In practice, choosing the appropriate starting method based on load characteristics is crucial to ensure safe and economical motor operation.

How to Choose Between Star and Delta Connections

In practical engineering, the first step in selecting a motor's wiring method is to consult the motor's nameplate. The nameplate usually indicates the voltage and corresponding connection method, such as "380V/220V, Δ/Y". This means a delta connection should be used with a 380V power supply, while a star connection should be used with a 220V supply, ensuring each phase winding receives its rated voltage. If the nameplate specifies only a single voltage and connection, such as "380V Δ", the wiring should strictly follow the nameplate specifications to ensure safe and reliable motor operation.

When selecting the wiring method, the motor's operating conditions and load requirements should be considered. If high starting torque or full-load output is required, a delta connection should be used. To reduce the starting current surge and protect the power grid and mechanical equipment, star-delta reduced-voltage starting can be applied, where the motor is designed to run in delta but starts in a star configuration. For long-term light-load operation, the motor may also be run in a star configuration to reduce heat generation and improve efficiency. Proper selection of the wiring method ensures the motor meets its design performance while maintaining operational safety and energy efficiency.

In general, a star connection is considered a low-voltage, low-current starting mode, while a delta connection represents a high-voltage, full-power operation mode. The core difference between the two lies in the voltage across the windings, which directly affects current, starting torque, and output power. Understanding motor wiring and its voltage, current, and power characteristics is essential for selecting appropriate starting methods, ensuring safe motor operation, and optimizing its engineering application.