- Home

- Technical College

- STEPPER MOTORS

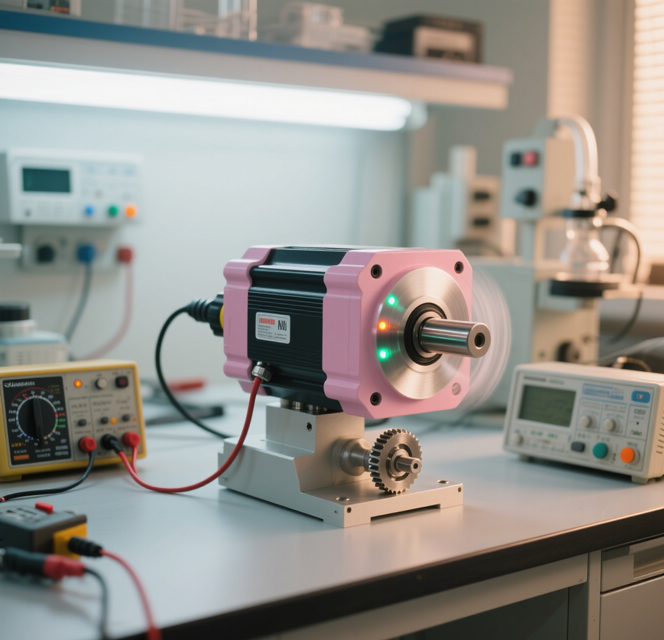

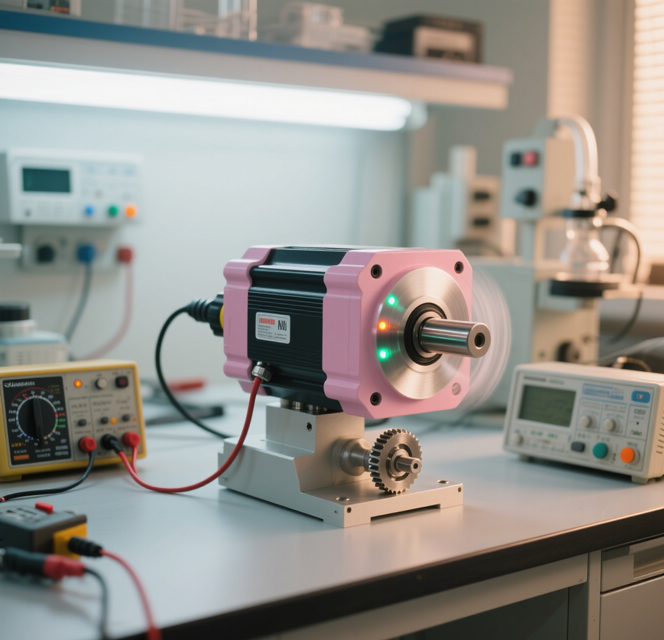

- Causes and Solutions for Abnormal Noise During Stepper Motor Operation

Causes and Solutions for Abnormal Noise During Stepper Motor Operation

When a stepper motor is in operation, it may produce abnormal noise that are often directly linked to specific faults. The characteristics of these noise can indicate issues within the mechanical, electrical, or control systems. Troubleshooting and resolving abnormal noise in stepper motor operation can be approached from the following six perspectives:  1. The setting of drive parameters will cause abnormal noise when the stepper motor is running. If the driver's current parameters are improperly configured, the stepper motor may produce rhythmic "clicking" noises due to insufficient output torque and resulting step loss. To eliminate such noise caused by improper current settings. The driver's output current should be calibrated—either via DIP switches or software—according to the motor's rated current specifications. Improper microstepping settings can lead to abnormal stepper motor performance. For example, if the microstepping value is too low, the motor may exhibit noticeable vibrations; if it is too high, the motor response speed may be reduced. A moderate microstepping mode (such as 1/4 or 1/8 step) should be selected to strike a balance between smooth operation and responsive performance. If the acceleration and deceleration curves are too steep, the stepper motor may lose steps during startup, stopping, or speed transitions, resulting in operational noise. To resolve this, the acceleration and deceleration time parameters should be increased, and the S-curve smoothing algorithm should be applied to optimize motion control.

1. The setting of drive parameters will cause abnormal noise when the stepper motor is running. If the driver's current parameters are improperly configured, the stepper motor may produce rhythmic "clicking" noises due to insufficient output torque and resulting step loss. To eliminate such noise caused by improper current settings. The driver's output current should be calibrated—either via DIP switches or software—according to the motor's rated current specifications. Improper microstepping settings can lead to abnormal stepper motor performance. For example, if the microstepping value is too low, the motor may exhibit noticeable vibrations; if it is too high, the motor response speed may be reduced. A moderate microstepping mode (such as 1/4 or 1/8 step) should be selected to strike a balance between smooth operation and responsive performance. If the acceleration and deceleration curves are too steep, the stepper motor may lose steps during startup, stopping, or speed transitions, resulting in operational noise. To resolve this, the acceleration and deceleration time parameters should be increased, and the S-curve smoothing algorithm should be applied to optimize motion control.

2. Mechanical structure problems cause abnormal noise when the stepper motor is running Loose or Improper installation can lead to mechanical resonance noise or abnormal component vibrations. The motor, coupling, and load-end mounting screws should be re-tightened, and the overall rigidity of the mechanical structure should be inspected simultaneously. Insufficient lubrication or worn components can lead to friction noise—such as a squeaking or periodic vibration sounds. To address this, lubrication should be replenished for guide rails, lead screws, and bearings, and any worn gears or bearings should be replaced.

3. Power supply and driver problems cause abnormal noise when the stepper motor runs Voltage fluctuations in the power supply can cause the motor to jitter or lose steps during operation. To resolve this, a voltage stabilizer should be installed, and the available power margin should be verified to ensure it meets the system's peek load requirements. If an internal fault in the driver results in abnormal current output (such as phase imbalance), the issue should be resolved either by replacing the entire unit or by diagnosing and repairing the driver chip and associated circuit modules. Poor contact at wiring terminals or electromagnetic interference may lead to control signal distortion/loss. The connections of motor and power line connectors should be inspected section by section, and the signal circuit should be upgraded to shielded cables with proper grounding to ensure signal integrity.

4. The problem of the motor body causes the stepper motor to make abnormal noise during operation Damage to internal motor components—such as short circuits between stator coil windings or fractured rotor bearing raceways, may result in persistent mechanical noise. In this case, the faulty motor should be either fully replaced or sent back for disassembly and factory repair to restore core functionality. If the selected motor operates under long-term overload due to insufficient torque, resulting in abnormal noise, the load torque parameters should be re-evaluated. Based on the findings, a higher-rated torque motor should be selected, or a reduction gearbox should be added to better match actual operating conditions.

5. Load problems cause abnormal noises during operation of the stepper motor Excessive load or mechanical jamming—such as blockage by foreign objects—can cause the motor to produce stall-relayed abnormal noise or periodic impact sounds. The running load should be reduced immediately, and any obstructions in the transmission chain should be identified and cleared. Excessive load inertia can lead to step loss and abnormal noise during motor startup or shutdown due to inertia imbalance. To achieve proper system inertia matching, the acceleration and deceleration time parameters should be extended, or an inertia adaptation device—such as a gearbox—should be added on the mechanical side.

6. Environmental interference and temperature cause abnormal noise during operation of the stepper motor The presence of strong electromagnetic interference source (such as an inverters/high-power equipment) can cause irregular step loss or high-frequency parasitic vibration in the motor. In such cases, the interfering equipment should be spatially isolated, magnetic ring filter should be installed on the signal cables, and sensitive wiring should be enclosed in metal shielding. Prolonged exposure to high temperatures may lead to motor magnet demagnetization or trigger the driver's thermal protection mechanisms. To prevent this, heat dissipation should be improved—such as by adding air cooling or heat sinks—and long-term overload operation of the equipment should be avoided.

Rapid diagnosis process of abnormal noise during operation of stepper motor. 1. Sound-Based Diagnosis: Regular "clicking" noise→ Step loss (check current, microstepping, load); high-frequency vibration sound comes from mechanical resonance (check installation, lubrication); random noise comes from interference or wiring problems. 2. Step-by-Step Troubleshooting: first adjust the drive parameters (current, subdivision) to observe whether it improves; check for issues in mechanical installation and verify that the load is appropriate; test and replace the drive or motor to confirm whether the hardware faults are present. 3. Diagnostic Tools: use an oscilloscope to detect whether the drive signal is functioning correctly; use a multimeter to measure the power supply voltage and check motor coil resistance.

By following the above rapid diagnosis process of abnormal noise in stepper motor operation, the root cause can be effectively identified and addressed with target solutions. If the issue persists, it is recommended to consult professional technicians or seek support from the equipment supplier.

1. The setting of drive parameters will cause abnormal noise when the stepper motor is running. If the driver's current parameters are improperly configured, the stepper motor may produce rhythmic "clicking" noises due to insufficient output torque and resulting step loss. To eliminate such noise caused by improper current settings. The driver's output current should be calibrated—either via DIP switches or software—according to the motor's rated current specifications. Improper microstepping settings can lead to abnormal stepper motor performance. For example, if the microstepping value is too low, the motor may exhibit noticeable vibrations; if it is too high, the motor response speed may be reduced. A moderate microstepping mode (such as 1/4 or 1/8 step) should be selected to strike a balance between smooth operation and responsive performance. If the acceleration and deceleration curves are too steep, the stepper motor may lose steps during startup, stopping, or speed transitions, resulting in operational noise. To resolve this, the acceleration and deceleration time parameters should be increased, and the S-curve smoothing algorithm should be applied to optimize motion control.

1. The setting of drive parameters will cause abnormal noise when the stepper motor is running. If the driver's current parameters are improperly configured, the stepper motor may produce rhythmic "clicking" noises due to insufficient output torque and resulting step loss. To eliminate such noise caused by improper current settings. The driver's output current should be calibrated—either via DIP switches or software—according to the motor's rated current specifications. Improper microstepping settings can lead to abnormal stepper motor performance. For example, if the microstepping value is too low, the motor may exhibit noticeable vibrations; if it is too high, the motor response speed may be reduced. A moderate microstepping mode (such as 1/4 or 1/8 step) should be selected to strike a balance between smooth operation and responsive performance. If the acceleration and deceleration curves are too steep, the stepper motor may lose steps during startup, stopping, or speed transitions, resulting in operational noise. To resolve this, the acceleration and deceleration time parameters should be increased, and the S-curve smoothing algorithm should be applied to optimize motion control. 2. Mechanical structure problems cause abnormal noise when the stepper motor is running Loose or Improper installation can lead to mechanical resonance noise or abnormal component vibrations. The motor, coupling, and load-end mounting screws should be re-tightened, and the overall rigidity of the mechanical structure should be inspected simultaneously. Insufficient lubrication or worn components can lead to friction noise—such as a squeaking or periodic vibration sounds. To address this, lubrication should be replenished for guide rails, lead screws, and bearings, and any worn gears or bearings should be replaced.

3. Power supply and driver problems cause abnormal noise when the stepper motor runs Voltage fluctuations in the power supply can cause the motor to jitter or lose steps during operation. To resolve this, a voltage stabilizer should be installed, and the available power margin should be verified to ensure it meets the system's peek load requirements. If an internal fault in the driver results in abnormal current output (such as phase imbalance), the issue should be resolved either by replacing the entire unit or by diagnosing and repairing the driver chip and associated circuit modules. Poor contact at wiring terminals or electromagnetic interference may lead to control signal distortion/loss. The connections of motor and power line connectors should be inspected section by section, and the signal circuit should be upgraded to shielded cables with proper grounding to ensure signal integrity.

4. The problem of the motor body causes the stepper motor to make abnormal noise during operation Damage to internal motor components—such as short circuits between stator coil windings or fractured rotor bearing raceways, may result in persistent mechanical noise. In this case, the faulty motor should be either fully replaced or sent back for disassembly and factory repair to restore core functionality. If the selected motor operates under long-term overload due to insufficient torque, resulting in abnormal noise, the load torque parameters should be re-evaluated. Based on the findings, a higher-rated torque motor should be selected, or a reduction gearbox should be added to better match actual operating conditions.

5. Load problems cause abnormal noises during operation of the stepper motor Excessive load or mechanical jamming—such as blockage by foreign objects—can cause the motor to produce stall-relayed abnormal noise or periodic impact sounds. The running load should be reduced immediately, and any obstructions in the transmission chain should be identified and cleared. Excessive load inertia can lead to step loss and abnormal noise during motor startup or shutdown due to inertia imbalance. To achieve proper system inertia matching, the acceleration and deceleration time parameters should be extended, or an inertia adaptation device—such as a gearbox—should be added on the mechanical side.

6. Environmental interference and temperature cause abnormal noise during operation of the stepper motor The presence of strong electromagnetic interference source (such as an inverters/high-power equipment) can cause irregular step loss or high-frequency parasitic vibration in the motor. In such cases, the interfering equipment should be spatially isolated, magnetic ring filter should be installed on the signal cables, and sensitive wiring should be enclosed in metal shielding. Prolonged exposure to high temperatures may lead to motor magnet demagnetization or trigger the driver's thermal protection mechanisms. To prevent this, heat dissipation should be improved—such as by adding air cooling or heat sinks—and long-term overload operation of the equipment should be avoided.

Rapid diagnosis process of abnormal noise during operation of stepper motor. 1. Sound-Based Diagnosis: Regular "clicking" noise→ Step loss (check current, microstepping, load); high-frequency vibration sound comes from mechanical resonance (check installation, lubrication); random noise comes from interference or wiring problems. 2. Step-by-Step Troubleshooting: first adjust the drive parameters (current, subdivision) to observe whether it improves; check for issues in mechanical installation and verify that the load is appropriate; test and replace the drive or motor to confirm whether the hardware faults are present. 3. Diagnostic Tools: use an oscilloscope to detect whether the drive signal is functioning correctly; use a multimeter to measure the power supply voltage and check motor coil resistance.

By following the above rapid diagnosis process of abnormal noise in stepper motor operation, the root cause can be effectively identified and addressed with target solutions. If the issue persists, it is recommended to consult professional technicians or seek support from the equipment supplier.