Causes of Stepper Motor Stalling

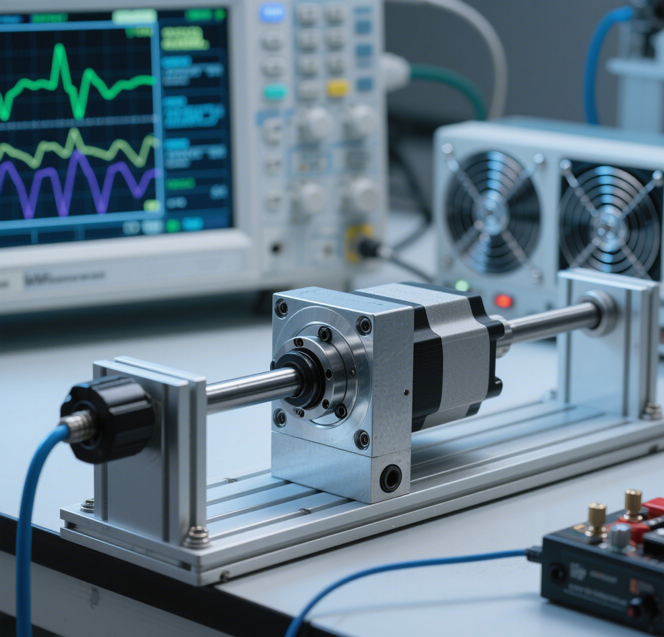

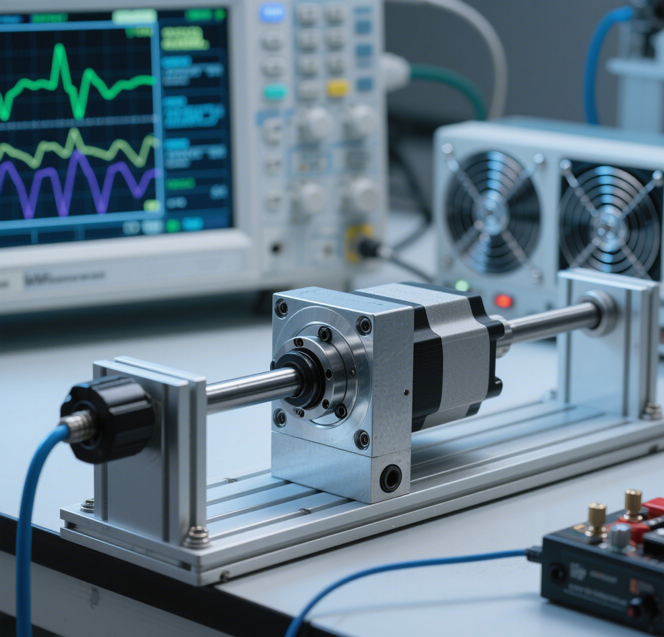

Stepper motor stalling refers to a condition where the rotor fails rotate properly due to excessive load or control anomalies. More specifically, stalling typically occurs when the motor's speed exceeds its maximum allowable threshold. When stalling, the motor often emits a high-pitched whine and is unable to function normally. The root causes of stalling can be classified into the following five categories:

The methods outlined above can help quickly identify the root cause of stepper motor stalling. For complex systems, a modular testing approach is recommended. First verify the independent operation of the stepper motor and driver, then gradually integrate the mechanical transmission components and load. Combining regular maintenance with optimized control parameters can significantly reduce the risk of stalling and ensure stable, reliable operation of the equipment.

1. Mechanical-related reasons cause the stepper motor to stall

1) Excessive mechanical resistance or transmission system seizure: Mechanical faults such as guide rail deformation, bearing jamming, or transmission component wear can significantly increase resistance to motion. These issues are particularly problematic when the natural frequency of the transmission system approaches the drive frequency, potentially leading to resonance. This may result in conditions like output shaft seizure, gear or screw transmission failure, or other mechanical breakdown that prevent the motor from overcoming frictional forces. 2) Load mismatch or imbalance: A sudden increase in load or prolonged operation under overload conditions can exceed the motor's rated torque capacity, easily resulting in load imbalance and causing the motor to stall.2. Electrical and drive factors cause stepper motor stalls

1) Abnormal drive signals: The quality of the drive signal directly affects the performance of the motor. If the pulse frequency is too high or the control signals are incorrect, the rotor's inertia may prevent it from keeping up with changes in the magnetic field. 2) Power supply and wiring issues: Fluctuations in Power supply voltage can cause unstable torque output. Insufficient voltage, low current limit, or poor electrical contact in the power supply lines can all weaken the motor's driving capability, increasing the likelihood of stalling. 3) Driver malfunction: Overheating, chip damage or improper current distribution within the driver can disrupt normal output, impairing the motor's performance and potentially leading to stalling.3. Improper control parameter settings leading to stepper motor stalling

1) Inadequate acceleration and deceleration time: If the acceleration and deceleration curves are improperly configured, particularly with overly short transition times. It can easily trigger motor stalling. A sudden spike in pulse frequency during acceleration may cause the motor speed to momentarily exceed the load's capacity, resulting in loss of synchronization and stalling. 2) Improper microstepping settings: Microstepping must strike a balance between positioning accuracy and available torque. Setting the micro step resolution too high can lead to insufficient starting torque, while setting it too low may result in excessively high speeds that increase the risk of stalling.4. The stepper motor is blocked due to problems with the motor itself

1) Internal structure failure: Worn bearings can significantly increase rotational resistance, while issues such as bearing damage, winding short circuits, or rotor eccentricity can directly obstruct the motor's operation and lead to stalling. Phase misconnection or motor selection error: Aging insulation in the windings can lead to current imbalances, while incorrect phase sequencing may disrupt the magnetic field, both of which can impair motor function. Additionally, using a motor model that is mismatched with the load requirements can result in inefficient operation or stalling.5. Environmental and maintenance factors cause stepper motor stalling

1) Abnormal temperature condition: high ambient temperature environment can degrade motor performance by intensifying internal heating and reducing the efficiency of the magnetic circuit, ultimately increasing the risk of stalling or failure. 2) Inadequate maintenance: A lack of regular cleaning and lubrication can lead to the gradual buildup of mechanical resistance and stalling. It is recommended to establish a fault log to record key data such as load status and current waveform at the time of stalling to support future diagnostics and analysis.The methods outlined above can help quickly identify the root cause of stepper motor stalling. For complex systems, a modular testing approach is recommended. First verify the independent operation of the stepper motor and driver, then gradually integrate the mechanical transmission components and load. Combining regular maintenance with optimized control parameters can significantly reduce the risk of stalling and ensure stable, reliable operation of the equipment.