Precautions for Using Ball Screw Linear Actuators

Ball screw linear actuators are precision transmission components widely used in CNC machine tools, automation equipment, precision instruments and other fields. To ensure their accuracy, lifespan and reliability, it is essential to follow these precautions:

Precautions for Using Lubricants for ball screw linear actuators

Ball screw linear actuators require lubricant (oil or grease) to be applied to the screw surface during operation. Insufficient lubrication can increase frictional loss, potentially leading to failure or shortened lifespan. MOONS' ball screw linear actuators come pre-greased (#2 lithium-based grease) on the screw surface at the factory. We recommend inspecting the lubricant on the screw surface after 2-3 months of operation. If the grease is noticeably contaminated, wipe away the old lubricant and apply fresh grease.Precautions for Using Ball Screw Linear Actuators

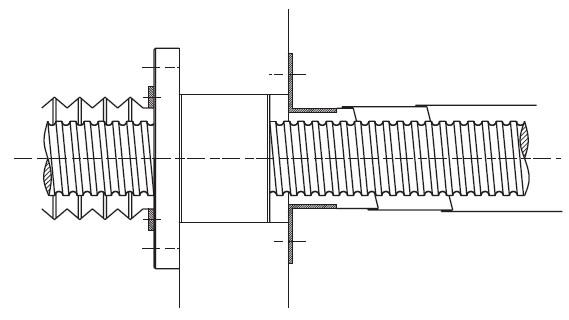

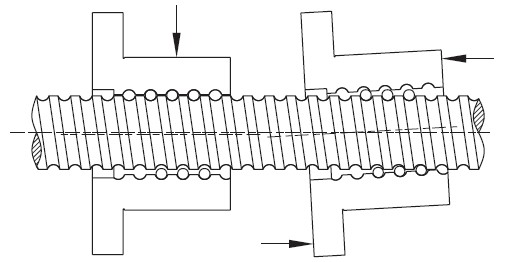

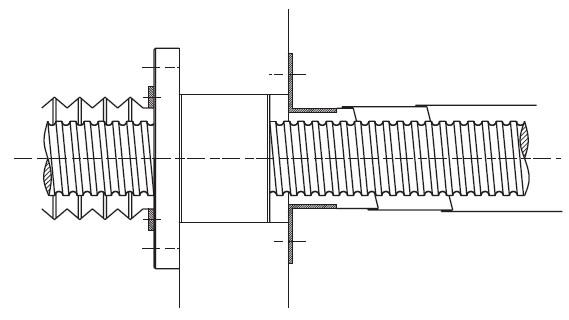

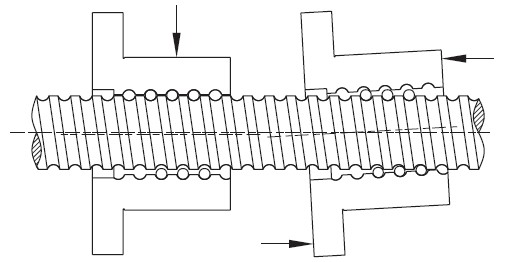

1. When installing or removing the ball screw nut, secure it to prevent it from falling due to its own weight. Never operate it beyond its effective travel range, as this can cause damage. 2. Misalignment or poor perpendicularity between the ball screw, bearing, guideway, and nut mount can cause the ball screw to deform. This can result in problems such as poor operation (sticking), abnormal noise, and shortened lifespan. Therefore, precise installation is critical. You must ensure the concentricity and perpendicularity of all components. 3. A ball screw is a mechanical component that generates axial thrust. Its structure cannot withstand radial and moment loads. Otherwise, this may cause the screw to bend and shorten its lifespan.

Ball Screw Linear Actuator Protection Precautions

1. Always operate ball screw linear actuators in a clean environment to prevent the intrusion of foreign matter such as dust and impurities. Contamination can lead to binding, malfunctions, or component damage. 2. Avoid using ball screw linear actuators in corrosive environments, as this may cause screw corrosion and result in operational failure. 3. When there is a risk of foreign matter intrusion, effective protective devices (such as protective covers) must be installed.