- Home

- Technical College

- STEPPER MOTORS

- How to Make a Stepper Motor Rotate According to a Sine Wave Pattern?

How to Make a Stepper Motor Rotate According to a Sine Wave Pattern?

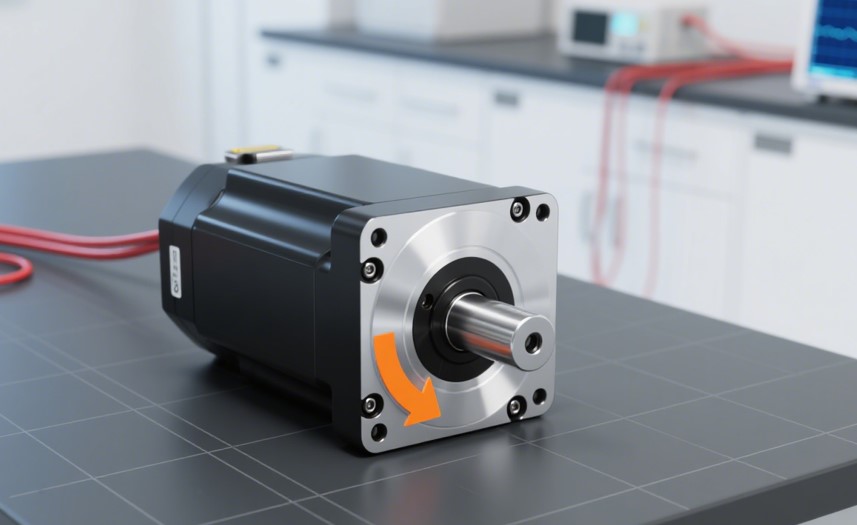

To make a stepper motor rotate according to a sine wave pattern, the sinusoidal speed curve must be converted into step control signals for the motor. This motion can be understood as acceleration and deceleration on the positive half of the Y-axis, and reverse acceleration and deceleration on the negative half. The following is the specific implementation method.

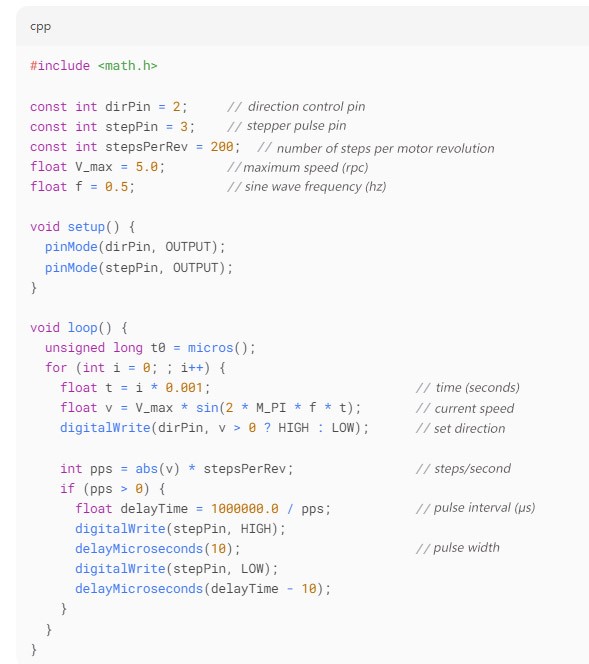

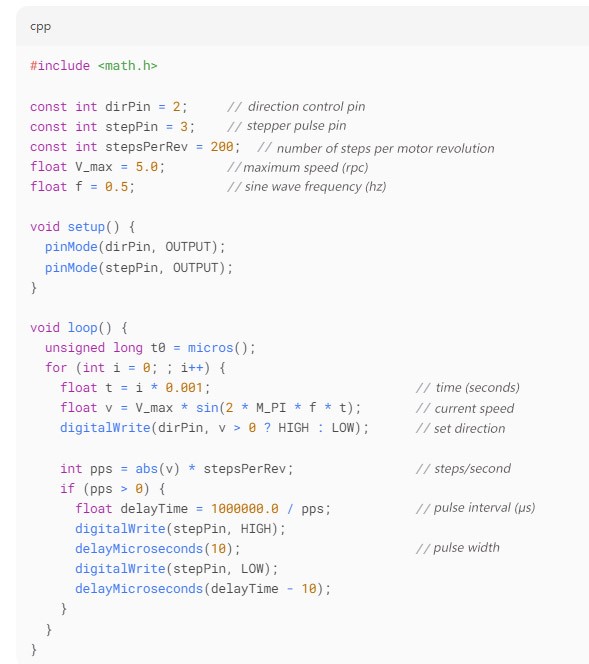

Microcontroller Code Example (Arduino) The key points are to use the sin() function to calculate speed in real time, and to dynamically adjust the step interval with delayMicroseconds() to achieve acceleration and deceleration. (4) Optimization and Precautions Improve Motion Smoothness with Microstepping: Enable microstepping mode on the stepper drive (1/16 recommended) for smoother motion. Use Timer Interrupts: For high-speed motion, use hardware timers to generate pulses to avoid blocking delays. Limiting speed: Ensure that Vmax does not exceed the maximum PPS of the motor and drives. Constrain Acceleration: If the motor does not start and stop smoothly, apply an acceleration constraint (e.g., S-curve) on top of the sine wave.

Microcontroller Code Example (Arduino) The key points are to use the sin() function to calculate speed in real time, and to dynamically adjust the step interval with delayMicroseconds() to achieve acceleration and deceleration. (4) Optimization and Precautions Improve Motion Smoothness with Microstepping: Enable microstepping mode on the stepper drive (1/16 recommended) for smoother motion. Use Timer Interrupts: For high-speed motion, use hardware timers to generate pulses to avoid blocking delays. Limiting speed: Ensure that Vmax does not exceed the maximum PPS of the motor and drives. Constrain Acceleration: If the motor does not start and stop smoothly, apply an acceleration constraint (e.g., S-curve) on top of the sine wave.

Using the above method, the stepper motor can accurately track the sinusoidal velocity curve and achieve smooth sinusoidal rotational motion.

Core Principle of Stepper Motor Sinusoidal Rotation

Generation of a Sinusoidal Speed Curve: Based on a sine function, the required speed command (frequency) is calculated in real time, ensuring the motor speed undergoes periodic acceleration and deceleration. Synchronous Direction Control: During the positive half-cycle of the sine wave (positive speed command), the motor rotates forward; during the negative half-cycle (negative speed command), the motor rotates in reverse. Improving Motion Smoothness: By using microstepping or increasing the step pulse frequency, the stepping sensation is significantly reduced, resulting in smoother motion that closely follows a sinusoidal trajectory.Steps to Realize Sinusoidal Rotation

(1) Generate a sinusoidal speed curve First, perform mathematical modeling and define the target speed curve as a sinusoidal speed function: v(t) = Vmax * sin(2πft), where Vmax is the maximum motor speed (steps/second) and f is the sine wave frequency (Hz), determining the duration of a full cycle (acceleration → deceleration → reverse acceleration → reverse deceleration). Then discretize time into small intervals Δt, giving tn=n*Δt, and compute v(tn) at each step. (2) Stepper Motor Control Speed Command Mapping: The discrete speed values v(tn) (unit: rps) are converted into the step pulse frequency output (PPS, unit: steps/second): PPS(tn)=v(tn) * steps_per_rev, where steps_per_rev is the motor's step angle resolution (steps/rev), representing the number of pulses required for one full revolution. Example: If steps_per_rev=200 and Vmax = 5rps, the maximum pulse frequency is: PPSmax = 5 * 200 = 1000 steps/second. Rotation direction control: The motor's rotation direction is determined in real time according to the sign of v(tn). When v(tn) > 0, the DIR pin is set to a forward level, driving the motor to rotate forward. When v(tn) < 0, the DIR pin is set to the reverse level, driving the motor to rotate backward. (3) Finally, achieve real-time control Microcontroller Code Example (Arduino) The key points are to use the sin() function to calculate speed in real time, and to dynamically adjust the step interval with delayMicroseconds() to achieve acceleration and deceleration. (4) Optimization and Precautions Improve Motion Smoothness with Microstepping: Enable microstepping mode on the stepper drive (1/16 recommended) for smoother motion. Use Timer Interrupts: For high-speed motion, use hardware timers to generate pulses to avoid blocking delays. Limiting speed: Ensure that Vmax does not exceed the maximum PPS of the motor and drives. Constrain Acceleration: If the motor does not start and stop smoothly, apply an acceleration constraint (e.g., S-curve) on top of the sine wave.

Microcontroller Code Example (Arduino) The key points are to use the sin() function to calculate speed in real time, and to dynamically adjust the step interval with delayMicroseconds() to achieve acceleration and deceleration. (4) Optimization and Precautions Improve Motion Smoothness with Microstepping: Enable microstepping mode on the stepper drive (1/16 recommended) for smoother motion. Use Timer Interrupts: For high-speed motion, use hardware timers to generate pulses to avoid blocking delays. Limiting speed: Ensure that Vmax does not exceed the maximum PPS of the motor and drives. Constrain Acceleration: If the motor does not start and stop smoothly, apply an acceleration constraint (e.g., S-curve) on top of the sine wave. Hardware Connection for Sinusoidal Rotation

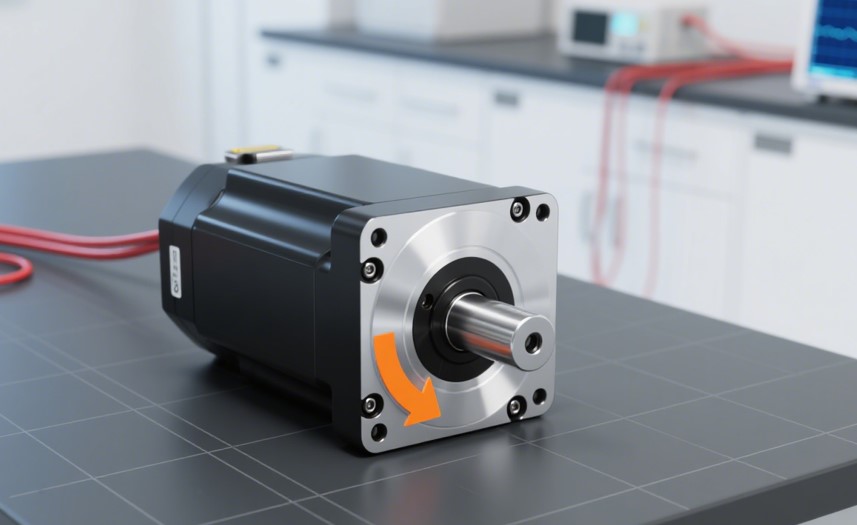

To achieve sinusoidal rotation of a stepper motor, a drive is required. The drive's DIR pin receives direction signals from the microcontroller (e.g., Arduino), and the STEP pin receives step pulse signals. The drive must also be connected to a power supply matching the motor's rated voltage, while the microcontroller provides the necessary logic control signals.To improve system performance, consider the following enhancements:

Precomputed Sine Tables — Precompute and store arrays of sinusoidal speed curve values offline, significantly reducing real-time computational load. Closed-Loop Feedback Control — Install a rotary encoder to obtain the actual motor position, and apply a PID algorithm to dynamically correct the drive signal, ensuring the actual motion trajectory precisely follows the theoretical sine curve.Using the above method, the stepper motor can accurately track the sinusoidal velocity curve and achieve smooth sinusoidal rotational motion.